Peter Lobner

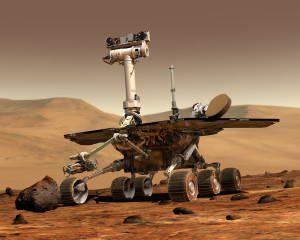

The Opportunity rover landed on Mars on January 25, 2004. It originally was designed for a 90 Sol mission (a Sol, one Martian day, is slightly longer than an Earth day at 24 hours and 37 minutes). The rover has proven to be far more durable than expected. A marathon is a long-distance running event with an official distance of 42.195 kilometers (26 miles and 385 yards). The rover Opportunity is the first extraterrestrial rover to complete this distance. The record time for this event was 11 years and 2 months.

Rover Opportunity; source: NASA

Rover Opportunity; source: NASA

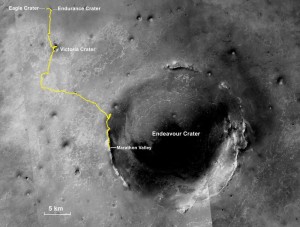

Map of the marathon trek; source: NASA

Map of the marathon trek; source: NASA

8 July 2015 Update:

On 2 July 2015, NASA/JPL uploaded an 8-minute time-lapse video of rover Opportunity’s marathon road trip on Mars. This compilation of images from the low-resolution, wide-field-of-view hazard-avoidance cameras on rover Opportunity between January 2004 and April 2015 shows the rover’s-eye-view of the Martian marathon from its landing location to the rim of Endeavour Crater. The sound in the video is synthesized from accelerometers on rover Opportunity. You can view this video using the link below. The view from the rover is in the left-hand panel, and a map of the rover’s path is on the right-hand panel of the video.

The URL for this embedded video is:

https://www.youtube.com/watch?v=3b1DxICZbGc&feature=youtu.be