Peter Lobner

1. Introduction

National Submarine Day, which occurs each year on 11 April, honors the anniversary of the day in 1900 when the U.S. Navy acquired the Holland VI submarine, which has been generally recognized as the world’s first modern submarine.

Similar, though slightly larger variants of the original Holland VI design also were acquired by the UK (1901 – 1904) and Japan (1904).

2. The Holland VI and the original U.S. Holland-class submarines

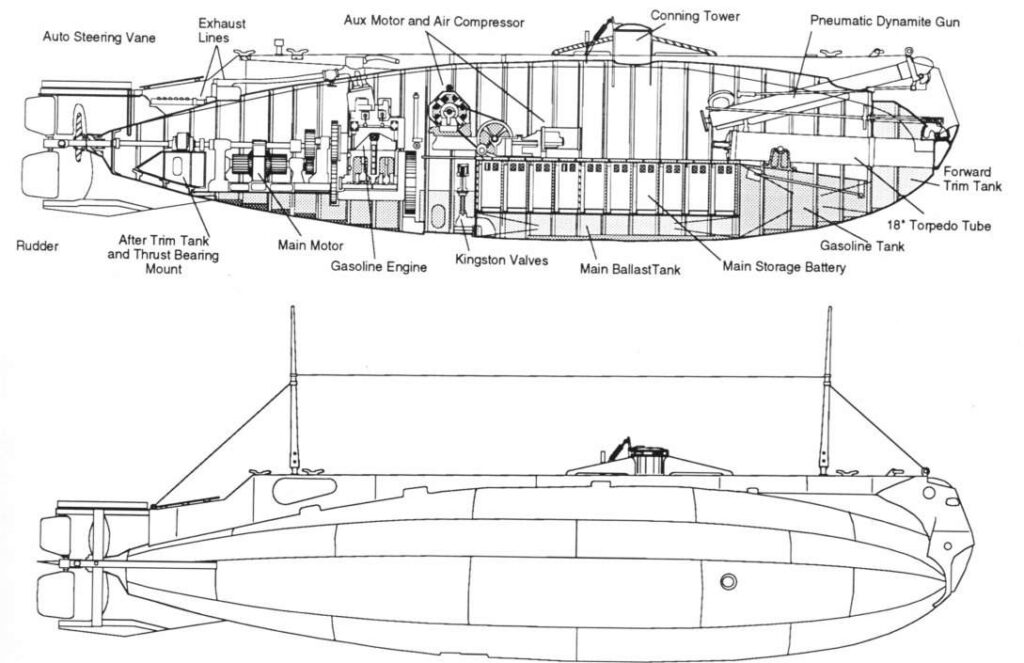

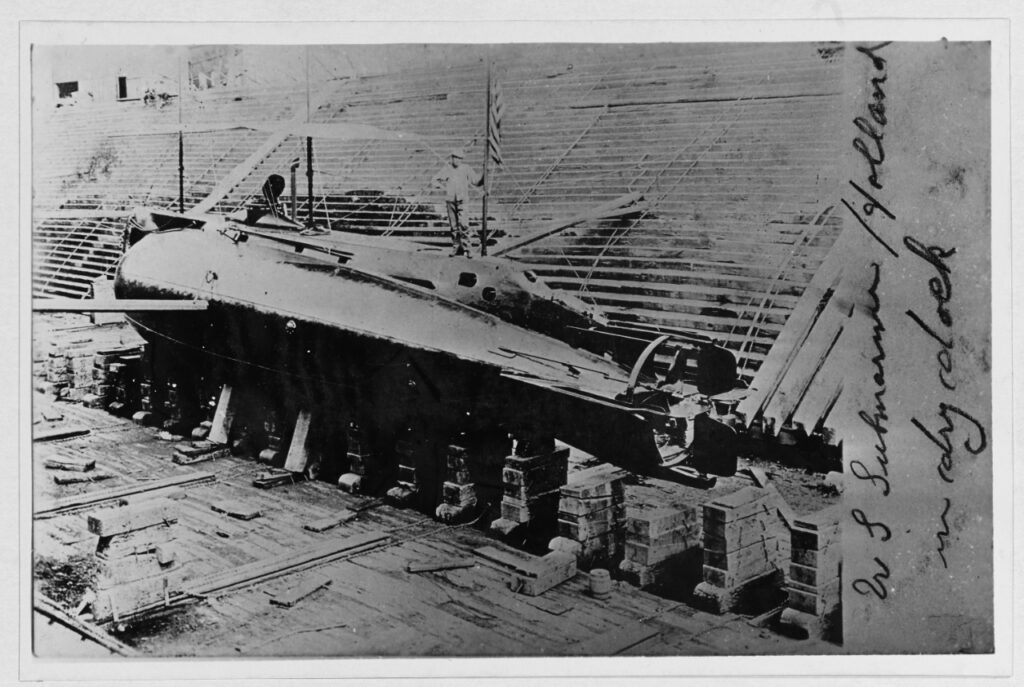

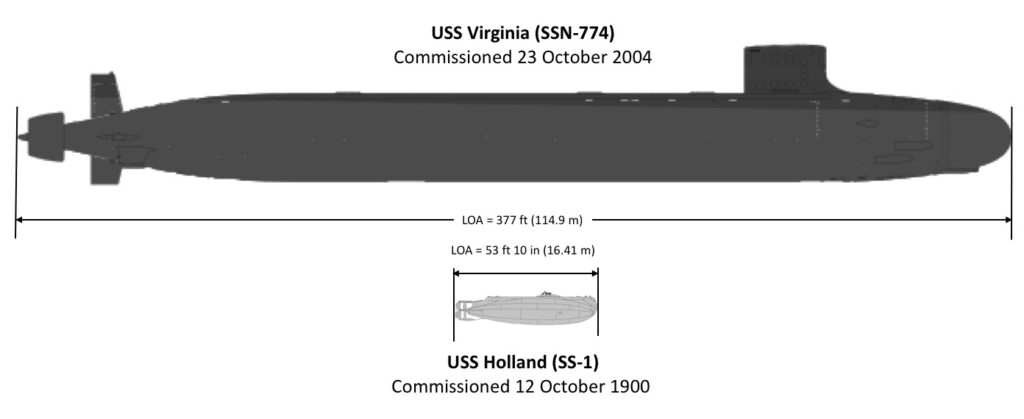

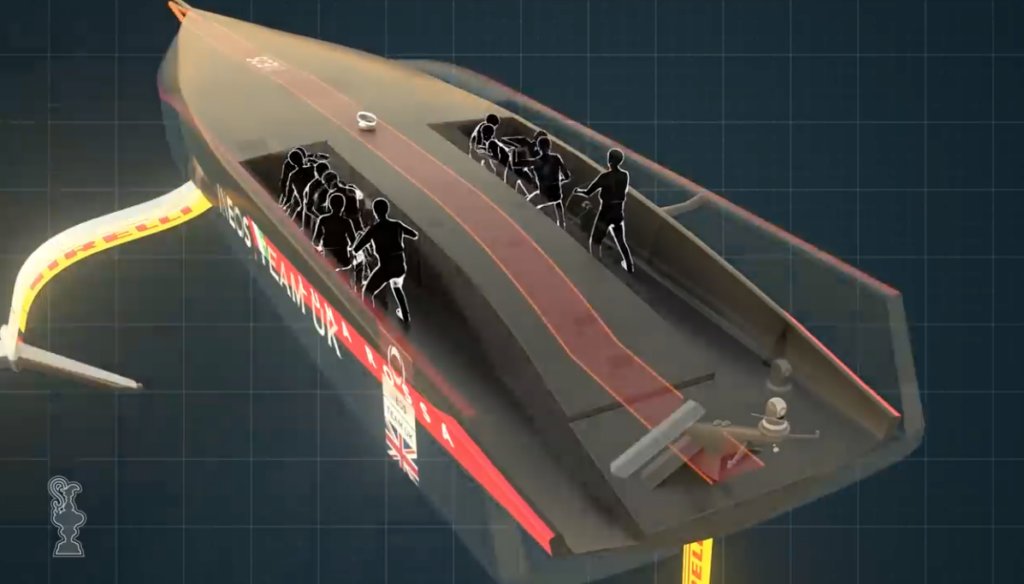

Designed in 1896 by Irish-American inventor John Phillip Holland and his Holland Torpedo Boat Company, the Holland VI was built at the Crescent Shipyard in Elizabeth, New Jersey, where Arthur Leopold Busch was the chief constructor / naval architect. The Holland VI was launched on 17 May 1897. This diminutive submarine (by today’s standards) had an overall length of 53 ft 10 in (16.41 m), displacements of 65 tons surfaced / 75 tons submerged, and was operated by a crew of six.

Source: Universal Ship Cancellation Society (USCS #3608)

The Holland VI brought together a host of impressive features for the first time in one vessel, including:

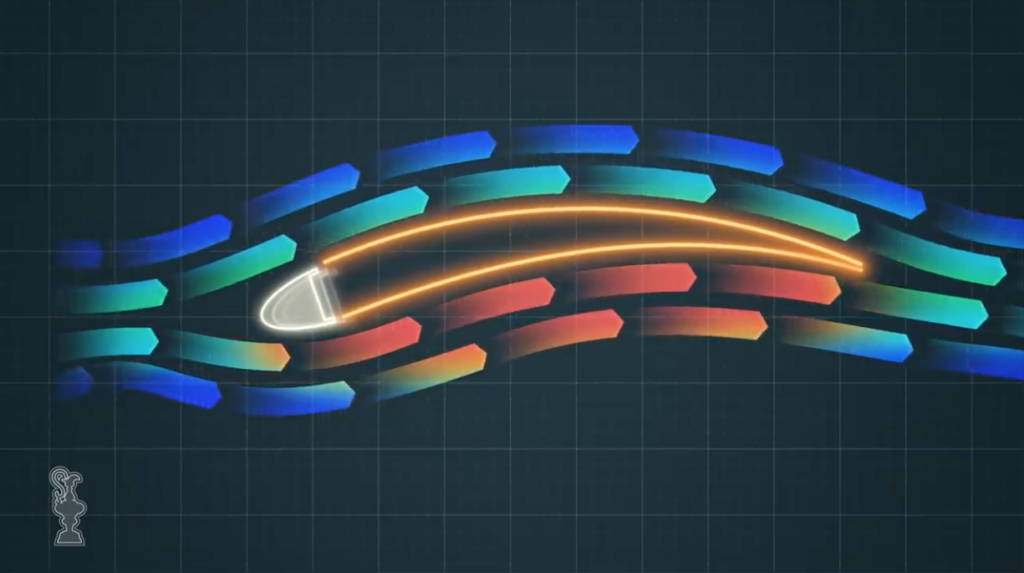

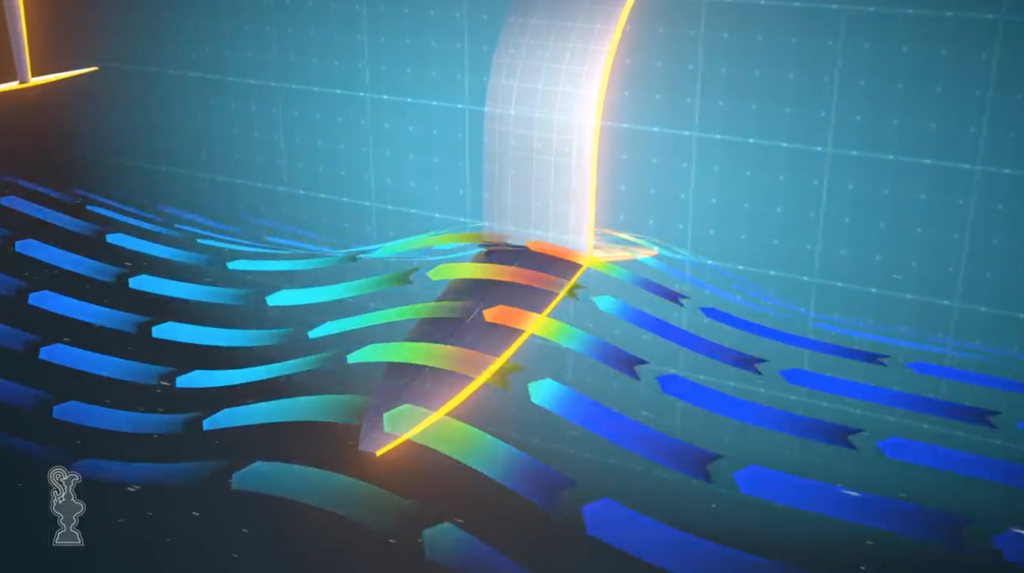

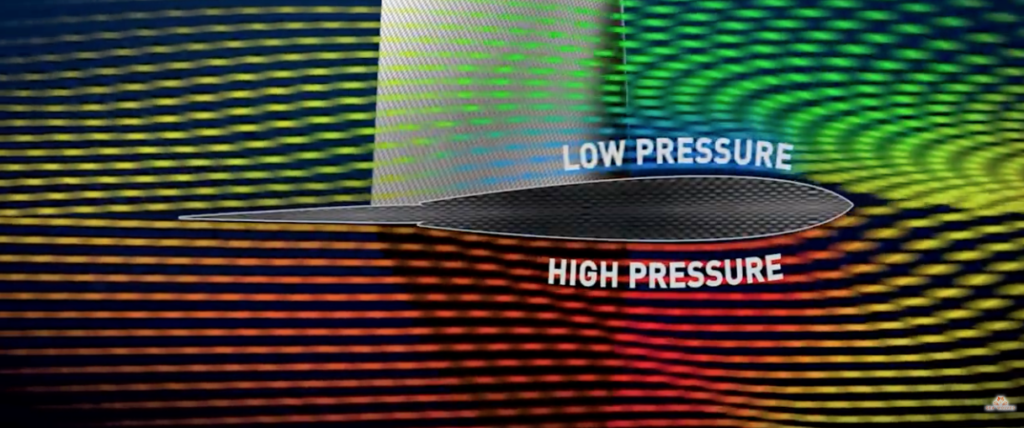

- Efficient hydrodynamic hull shape [teardrop-shape with bulbous bow and tapered stern] with good seakeeping ability on the open ocean.

- Separate main and auxiliary ballast systems enable rapid diving and surfacing with minimial changes to the longitudinal center of gravity while underway.

- Accomplished by operating with full or nearly full ballast tanks when submerged.

- Allowed precise control of trim angle while submerged.

- Able to dive to and accurately maintain a significant depth [up of 75 feet (23 m)].

- Diving planes provide the means to precisely control depth [stern planes only, located behind the propeller].

- Dual propulsion systems driving a single propeller at the stern.

- Internal combustion engine provides reliable power on the surface, enabling long transits while charging the batteries [up to 200 nautical miles (370 km) at 6 knots]

- Lead-acid storage batteries provide power to run submerged for a considerable distance [about 30 nautical miles (56 km) at 5.5 knots].

- Conning tower for directing ship and weapons activities on the surface or semi-submerged.

- No periscope. View ports around the top of the conning tower provided the commander with intermittent views while “porpoising” semi-submerged near the surface.

- Offensive weapons systems.

- One reloadable torpedo tube at the bow, with three self-propelled torpedoes carried internally.

- One pneumatic dynamite gun at the bow that, on the surface, fired large projectiles, sometimes called “aerial torpedoes.” [This was subsequently removed].

John P. Holland first demonstrated the Holland VI to the U.S. Navy on 17 March 1898. It appears that Submarine Day originally was celebrated to mark anniversaries of this date.

The interior space was one contiguous compartment. Source: Navsource.com

The U.S. Navy purchased the Holland VI for $150,000 on 11 April 1900. The Navy renamed and commissioned the submarine as the USS Holland on 12 October 1900. While the Navy previously owned and operated two submarines, Alligator (1862 – 63) and Intelligent Whale (1869 – 73), the USS Holland was the first commissioned submarine in the fleet. Lieutenant H.H. Caldwell became the first commanding officer of a modern commissioned submarine.

On 25 August 1905, the USS Holland made history by being the first American submarine to carry a U.S. President, Theodore Roosevelt, while she ran submerged for 55 minutes.The Navy ordered six more Holland-class submarines from the Electric Boat Company, which was founded in 1899 and had acquired the Holland Torpedo Boat Company and the continuing services of John P. Holland as Manager. Patent US702729 was granted on 17 June 1902 for Holland’s submarine design and assigned to Electric Boat Company.

Source: Naval Institute photo archive

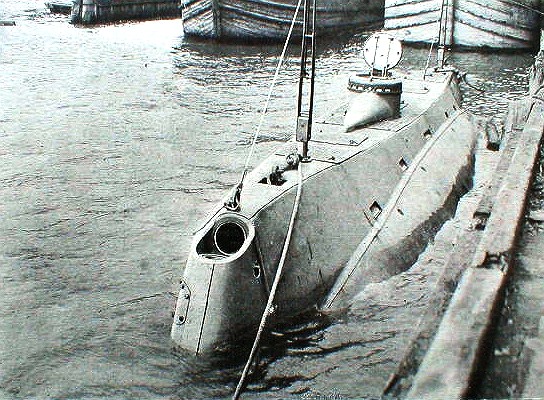

Source: Naval History and Heritage Command

pneumatic dynamite gun at the bow and the open conning tower amidships.

Source: Scientific American 1898 via Wikimedia Commons

Source: screenshot from “Submarine #1” video (2022)

The U.S. Navy’s Holland-class subs rapidly became obsolete as submarine technology advanced. USS Holland finished out her naval career in Norfolk, VA, was stricken from the Navy Register of Ships on 21 November 1910, and was sold for scrap in 1913. The USS Holland did not receive its “SS-1” designation until the Navy’s modern hull classification system was instituted on 17 July 1920.

3. The UK Holland-class submarines

In their online history, BAE Systems reports, “Following meetings with the Admiralty, an agreement was made on 27th October 1900 between the Electric Boat Company and Vickers Sons & Maxim Ltd of Barrow-in-Furness, giving Vickers 25-year license to manufacture the Holland-class of submarines, using Electric Boats patents.”

Vickers built five Holland-class subs for the Royal Navy. These were somewhat larger than their U.S. counterparts, with a length of 63 ft 4 in (19.3 m), a submerged displacement of 107 tons and a crew of eight.

The first sub, designated Holland 1, was launched in 1901. After 12 years of service, it was decommissioned in 1913 and sank at sea while under tow near Plymouth, on its way to be scrapped. The location of the sunken sub was discovered in 1981 and the largely intact vessel was raised in 1983. Today, the Holland 1 is on display at the Royal Navy’s Submarine Museum in Gosport, UK, in a climate-controlled environment designed to arrest further corrosion.

Source: screenshot from The National Museum of the Royal Navy video (2022)

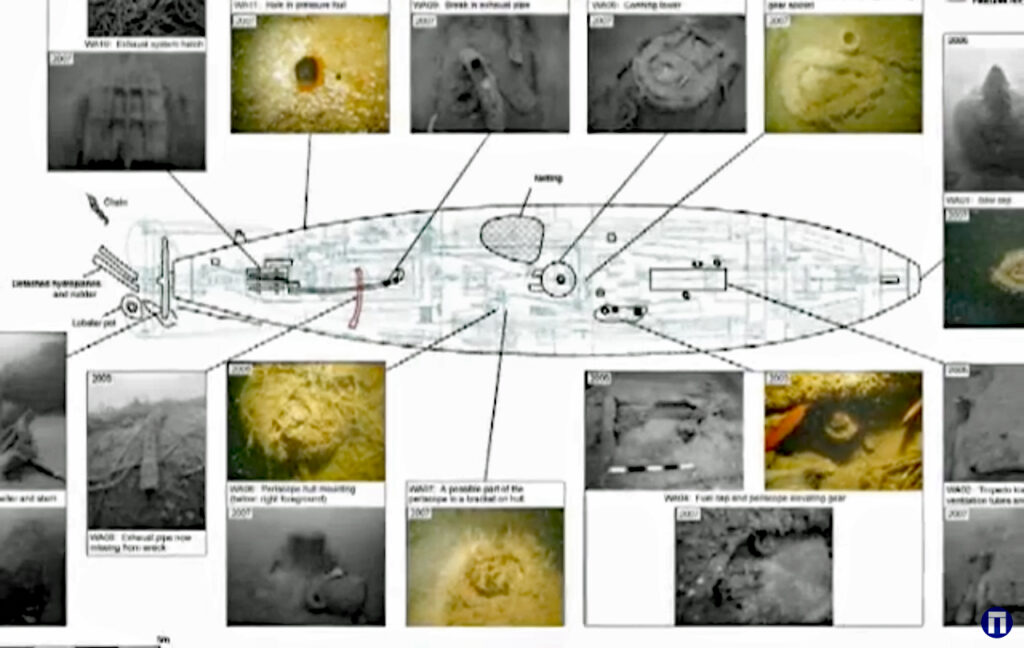

The last of the UK’s Holland-class submarines, Holland 5, was launched in 1904. After eight years in service, Holland 5 sank off the coast of Sussex in 1912 while being towed for decommissioning. In 1985, the intact, but encrusted, submarine was located on the seabed at a depth of 35 meters (115 ft), where it remains today, subject to the Protection of Wrecks Act 1973.

Source: screenshot from Wessex Archaeology video (2010)

4. The Japanese Holland-class submarines

Japanese representatives had sailed aboard Holland IV during early testing in 1898 and during trials on the Potomac River in 1900. During the Russo-Japanese War, the Japanese government purchased five “improved” Holland-class submarines from the Electric Boat Company in great secrecy, since the U.S. was a “neutral” nation. These submarines had a length of 67 ft (20.4 m) and a submerged displacement of 126 tons. They were delivered to Japan partially assembled in December 1904. Assembly was completed at the Yokosuka Naval Arsenal, the crews were trained, and the submarines were ready for combat operations in August 1905. None saw action before the war ended in September 1905. They served as training boats until being retired from service 1920.

(Type 7-P) subs. Source: Dynamic America, edited by J. Niven, 1960,

via Gary McCue

5. Comparison with today’s nuclear-powered submarines

Since the first production run of Holland-class submarines built for the U.S. Navy, Electric Boat Company (now General Dynamics Electric Boat) has been delivering submarines to the Navy for more than 120 years.

The Navy’s Virginia-class SSNs, which started entering the fleet in 2004 with USS Virginia(SSN-774), are 7,800 ton behemoths in comparison to the USS Holland.

Sources: composite adapted from Wikiwand (SSN-774) & Navsource (SS-1)

Almost 20 years later, the latest Virginia-class Block V SSNs are even bigger, with an overall length of 460 ft (140 m) and a submerged displacement of over 10,000 tons. The largest submarines currently in the Navy’s fleet are the aging Ohio-class SSBNs (strategic missile submarines) and SSGNs (cruise missile submarines). With an overall length of 560 ft (170 m) and a submerged displacement of about 18,750 tons, the Ohio-class subs dwarf all the other U.S. subs.

Since 2018, the U.S. Navy has been testing a large, autonomous, unmanned underwater vehicle (UUV), Echo Voyager, which is 51 feet (15.5 meters) long and has a displacement of about 50 tons. This is approximately the same size as the USS Holland (SS-1).

John P. Holland would be amazed at the progress made in submarine design and operation over the 123 years since the USS Holland was acquired by the U.S. Navy in 1990 and commissioned that same year.

Enjoy National Submarine Day on 11 April, and remember that, in the U.S., it’s pronounced “sub-marine-er,” not “sub-mariner,” as they say in the UK and in Marvel Comics. If you’re going to dress up for the occasion, may I suggest this stylish T-shirt.

For more information

- “USS Holland SS-1 – Some facts and History,” USS Holland AS-32 Association: https://www.ussholland.org/usshollandss1.html

- Carol Johnk, “National Submarine Day,” Lichtenberger Engineering Library, University of Iowa, 10 April 2015: https://blog.lib.uiowa.edu/eng/national-submarine-day/

- “Navy Virginia (SSN-774) Class Attack Submarine Procurement: Background and Issues for Congress,” Congressional Research Service report RL32418, updated 21 December 2022: https://sgp.fas.org/crs/weapons/RL32418.pdf

- “Navy Large Unmanned Surface and Undersea Vehicles: Background and Issues for Congress,” Congressional Research Service report R45757, updated 21 December 2022: https://sgp.fas.org/crs/weapons/R45757.pdf

- “RN Subs – 1901 – 1913: Holland Class,” RN Subs in Association with the Barrow Submariners Association: http://rnsubs.co.uk/boats/subs/holland-class.html

- “Holland-class Submarines – The Royal Navy’s first submarines,” BAE Systems: https://www.baesystems.com/en/heritage/holland-class-submarines

- Gary McCue, “Japanese ‘Holland’ Submarines (Type 7-P),” Military Honors: http://militaryhonors.sid-hill.us/history/gwmjh_archive/Submarines/Holland_7J.html

Patent

- Patent US702729, “Submarine Boat,” Inventor: John P. Holland, Filed 5 October 1900, Granted 17 June 1902, Assigned to Electric Boat Company: https://patents.google.com/patent/US702729A/en?oq=US702729

Videos – USS Holland

- “‘No Deck to Strut Upon’ 1971 U.S. Navy Film, John P. Holland and Development of the Submarine, 80114,” (28.06 min), Periscope Films, posted online 7 June 2022: https://www.youtube.com/watch?v=mVzhn3X93Hg

- “First US Navy Submarine: USS Holland,” (4.49 min), posted by Military History Visualized, 5 April 2016: https://www.youtube.com/watch?v=iBx1qyEILLk

- “Uncovering Middlesex County August 2018: USS Holland (SS 1),” (1.00 min), posted by Middlesex County NJ Gov’t, 14 August 2018: https://www.youtube.com/watch?v=NHHmVCcSYGo

- “Submarine #1,” (10.26 min), posted by Dark Seas, 11 April 2022: https://www.youtube.com/watch?v=FOeZJieYqRE

- “USS Holland (Submarine) Trials,” (7.10 min), posted by AP Archives, 28 July 2015: https://www.youtube.com/watch?v=44EB6xcWxKg

- “HISTORY 1904! United States Navy’s first modern submarine..USS Holland,” (7.00 min), posed by Sam Ash, 3 February 2023: https://www.youtube.com/watch?v=oANnFeIz10k

- “1/350 USS Holland (SS-1) 1,” (15.41 min, 3-D scale modeling project), posted by Sooo, 28 June 2022: https://www.youtube.com/watch?v=Qvrgpk7cHRE

- “The Story of John Philip Holland,” (8.23 min), posted by Cliffs of Moher Experience, 16 August 2000: https://www.youtube.com/watch?v=kklHONpO_z0

Videos – Royal Navy Holland-class submarines

- “Holland-class submarines – The Royal Navy’s first submarines,” BAE Systems: https://www.baesystems.com/en/heritage/holland-class-submarines

- “The Royal Navy’s first submarine, Holland 1, turns 120 years old in 2021,” (2:56 min), posted by The National Museum of the Royal Navy, 27 September 2021:https://www.youtube.com/watch?v=KgzHUFc4aQM

- “HMS/m Holland V: Diving on an early Royal Navy submarine,” (7.27 min), posted by Wessex Archaeology, 8 July 2010: https://www.youtube.com/watch?v=aRx3-ofgqK0

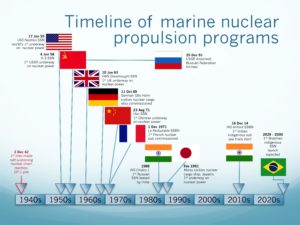

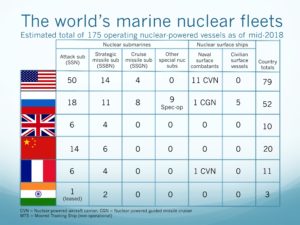

Source: two charts by author

Source: two charts by author

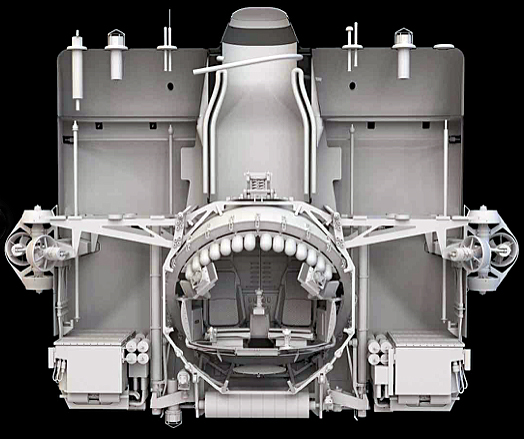

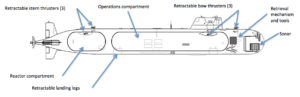

Kashalot notional diagram showing deployed positioning thrusters, landing legs and tools for working on the bottom. Source: http://nvs.rpf.ru/nvs/forum

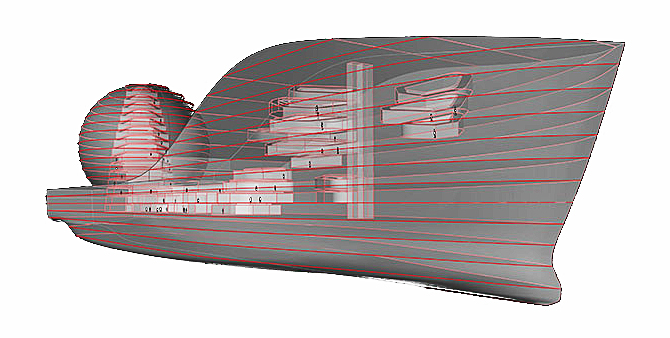

Kashalot notional diagram showing deployed positioning thrusters, landing legs and tools for working on the bottom. Source: http://nvs.rpf.ru/nvs/forum General arrangement of a Russian mothership carrying a small special operations submarine. Source: http://gentleseas.blogspot.com/2015/08/russias-own-jimmy-carter-special-ops.html

General arrangement of a Russian mothership carrying a small special operations submarine. Source: http://gentleseas.blogspot.com/2015/08/russias-own-jimmy-carter-special-ops.html

Harpsichord-2R-PM. Source: http://vpk-news.ru/articles/30962

Harpsichord-2R-PM. Source: http://vpk-news.ru/articles/30962 Source: https://russianmilitaryanalysis.wordpress.com/tag/9m730/

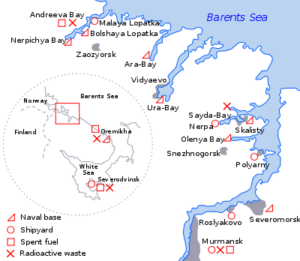

Source: https://russianmilitaryanalysis.wordpress.com/tag/9m730/ Olenya Bay is near Murmansk. Source: Google Maps

Olenya Bay is near Murmansk. Source: Google Maps

Mothership BS-136 Orenburg at Oleyna Bay. Source: Source: http://www.air-defense.net/

Mothership BS-136 Orenburg at Oleyna Bay. Source: Source: http://www.air-defense.net/

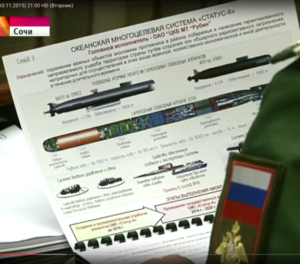

The Russian TV “reveal” of the Oceanic Multipurpose System Status-6 November 2015. Source: https://russianmilitaryanalysis.wordpress.com/tag/9m730/

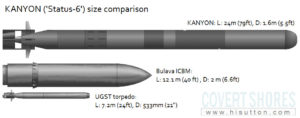

The Russian TV “reveal” of the Oceanic Multipurpose System Status-6 November 2015. Source: https://russianmilitaryanalysis.wordpress.com/tag/9m730/ Source: http://www.hisutton.com/

Source: http://www.hisutton.com/