Peter Lobner

1. Background

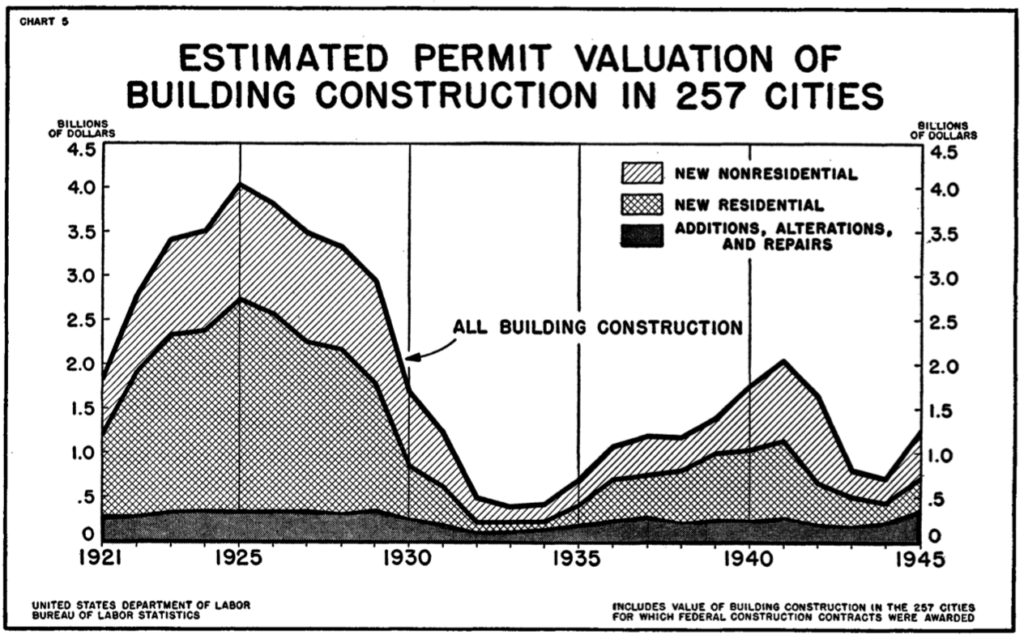

At the start of World War II (WW II), US home ownership had dropped to a low of 43.6% in 1940, largely as a consequence of the Great Depression and the weak US economy in its aftermath. During WW II, the War Production Board issued Conservation Order L-41 on 9 April 1942, placing all construction under rigid control. The order made it necessary for builders to obtain authorization from the War Production Board to begin construction costing more than certain thresholds during any continuous 12-month period. For residential construction, that limit was $500, with higher limits for business and agricultural construction. The impact of these factors on US residential construction between 1921 and 1945 is evident in the following chart, which shows the steep decline during the Great Depression and again after Order L-41 was issued.

US Department of Labor, Bulletin No. 915

By the end of WW II, the US had an estimated 7.6 million troops overseas. The War Production Board revoked L-41 on 15 October 1945, five months after V-E (Victory in Europe) day on 8 May 1945 and six weeks after WW II ended when Japan formally surrendered on 2 September 1945. In the five months since V-E day, about three million soldiers had already returned to the US. After the war’s end, the US was faced with the impending return of several millions more veterans. Many in this huge group of veterans would be seeking to buy homes in housing markets that were not prepared for their arrival. Within the short span of a year after Order L-41 was revoked, the monthly volume of private housing expenditures increased fivefold. This was just the start of the post-war housing boom in the US.

In a March 1946 Popular Science magazine article entitled “Stopgap Housing,” the author, Hartley Howe, noted, “ Even if 1,200,000 permanent homes are now built every year – and the United States has never built even 1,000,000 in a single year – it will be 10 years before the whole nation is properly housed. Hence, temporary housing is imperative to stop that gap.” To provide some immediate relief, the Federal government made available many thousands of war surplus steel Quonset huts for temporary civilian housing.

Facing a different challenge in the immediate post-war period, many wartime industries had their contracts cut or cancelled and factory production idled. With the decline of military production, the U.S. aircraft industry sought other opportunities for employing their aluminum, steel and plastics fabrication experience in the post-war economy.

2. Post-WW II prefab aluminum and steel houses in the US

In the 2 September 1946 issue of Aviation News magazine, there was an article entitled “Aircraft Industry Will Make Aluminum Houses for Veterans,” that reported the following:

- “Two and a half dozen aircraft manufacturers are expected soon to participate in the government’s prefabricated housing program.”

- “Aircraft companies will concentrate on FHA (Federal Housing Administration) approved designs in aluminum and its combination with plywood and insulation, while other companies will build prefabs in steel and other materials. Designs will be furnished to the manufacturers.”

- “Nearly all war-surplus aluminum sheet has been used up for roofing and siding in urgent building projects; practically none remains for the prefab program. Civilian Production Administration has received from FHA specifications for aluminum sheet and other materials to be manufactured, presumably under priorities. Most aluminum sheet for prefabs will be 12 to 20 gauge – .019 – .051 inch.”

In October 1946, Aviation News magazine reported, “The threatened battle over aluminum for housing, for airplanes and myriad postwar products in 1947 is not taken too seriously by the National Housing Agency, which is negotiating with aircraft companies to build prefabricated aluminum panel homes at an annual rate as high as 500,000.”……”Final approval by NHA engineers of the Lincoln Homes Corp. ‘waffle’ panel (aluminum skins over a honeycomb composite core) is one more step toward the decision by aircraft companies to enter the field.…..Aircraft company output of houses in 1947, if they come near meeting NHA proposals, would be greater than their production of airplanes, now estimated to be less than $1 billion for 1946.”

In late 1946, the FHA Administrator, Wilson Wyatt, suggested that the War Assets Administration (WAA), which was created in January 1946 to dispose of surplus government-owned property and materials, temporarily withhold surplus aircraft factories from lease or sale and give aircraft manufacturers preferred access to surplus wartime factories that could be converted for mass-production of houses. The WAA agreed.

Under the government program, the prefab house manufacturers would have been protected financially with FHA guarantees to cover 90% of costs, including a promise by Reconstruction Finance Corporation (RFC) to purchase any homes not sold.

Many aircraft manufacturers held initial discussions with the FHA, including: Douglas, McDonnell, Martin, Bell, Fairchild, Curtis-Wright, Consolidated-Vultee, North American, Goodyear and Ryan. Boeing did not enter those discussions and Douglas, McDonnell and Ryan exited early. In the end, most aircraft manufacturer were unwilling to commit themselves to the postwar prefab housing program, largely because of their concerns about disrupting their existing aircraft factory infrastructure based on uncertain market estimates of size and duration of the prefab housing market and lack of specific contract proposals from the FHA and NHA.

The original business case for the post-war aluminum and steel pre-fabricated houses was that they could be manufactured rapidly in large quantities and sold profitably at a price that was less than conventional wood-constructed homes. Moreover, the aircraft manufacturing companies restored some of the work volume lost after WW II ended and they were protected against the majority of their financial risk in prefab house manufacturing ventures.

Not surprisingly, building contractors and construction industry unions were against this program to mass-produce prefabricated homes in factories, since this would take business away from the construction industry. In many cities the unions would not allow their members to install prefabricated materials. Further complicating matters, local building codes and zoning ordnances were not necessarily compatible with the planned large-scale deployment of mass-produced, prefabricated homes.

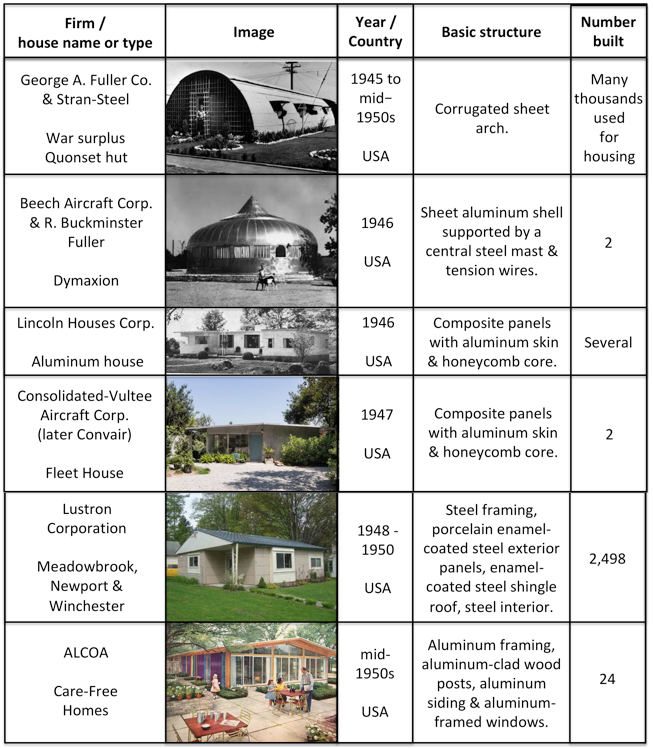

The optimistic prospects for manufacturing and erecting large numbers of prefabricated aluminum and steel homes in post-WW II USA never materialized. Rather than manufacturing hundreds of thousands of homes per year, the following five US manufacturers produced a total of less than 2,600 new aluminum and steel prefabricated houses in the decade following WW II: Beech Aircraft, Lincoln Houses Corp., Consolidated-Vultee, Lustron Corp. and Aluminum Company of America (Alcoa). In contrast, prefabricators offering more conventional houses produced a total of 37,200 units in 1946 and 37,400 in 1947. The market demand was there, but not for aluminum and steel prefabricated houses.

US post-WW II prefabricated aluminum and steel houses

These US manufacturers didn’t play a significant part in helping to solve the post-WW II housing shortage. Nonetheless, these aluminum and steel houses still stand as important examples of affordable houses that, under more favorable circumstances, could be mass-produced even today to help solve the chronic shortages of affordable housing in many urban and suburban areas in the US.

Some of the US post-WW II housing demand was met with stop gap, temporary housing using re-purposed, surplus wartime steel Quonset huts, military barracks, light-frame temporary family dwelling units, portable shelter units, trailers, and “demountable houses,” which were designed to be disassembled, moved and reassembled wherever needed. You can read more about post-WW II stop gap housing in the US in Hartley Howe’s March 1946 article in Popular Science (see link below).

The construction industry ramped up rapidly after WW II to help meet the housing demand with conventionally-constructed permanent houses, with many being built in large-scale housing tracts in rapidly expanding suburban areas. Between 1945 and 1952, the Veterans Administration reported that it had backed nearly 24 million home loans for WW II veterans. These veterans helped boost US home ownership from 43.6% in 1940 to 62% in 1960.

Two post-WW II US prefabricated aluminum and steel houses have been restored and are on public display in the following museums:

- The only remaining Dymaxion House is exhibited at the Henry Ford Museum of American Innovation in Dearborn, Michigan. A link to that exhibit is here: https://www.thehenryford.org/visit/henry-ford-museum/exhibits/dymaxion-house/

- Lustron #549, a Westchester Deluxe 02 model, is on display in the Ohio History Center Museum in Columbus, Ohio. The museum website is here: https://www.ohiohistory.org/visit/exhibits/ohio-history-center-exhibits

In addition, you can visit several WW II Quonset huts at the Seabees Museum and Memorial Park in North Kingstown, Rhode Island. None are outfitted like a post-WW II civilian apartment. The museum website is here: https://www.seabeesmuseum.com

You’ll find more information in my articles on specific US post-WW II prefabricated aluminum and steel houses at the following links:

- War surplus steel Quonset huts: https://lynceans.org/wp-content/uploads/2020/06/Quonset-huts-converted.pdf

- Beech Aircraft & R. Buckminster Fuller’s aluminum Dymaxion house: https://lynceans.org/wp-content/uploads/2020/06/Beech-Aircraft-Buckminster-Fuller-Dymaxion-house-converted.pdf

- Lincoln Houses Corp’s aluminum panel houses: https://lynceans.org/wp-content/uploads/2020/06/Lincoln-Houses-Corp-aluminum-panel-house-converted.pdf

- Consolidated Vultee’s aluminum panel houses: https://lynceans.org/wp-content/uploads/2020/06/Consolidated-Vultee-aluminum-panel-Fleet-House-converted.pdf

- Lustron Corp’s steel houses: https://lynceans.org/wp-content/uploads/2020/06/Lustron-Corporation-steel-house-converted.pdf

- Alcoa’s Care-Free aluminum houses: https://lynceans.org/wp-content/uploads/2020/06/Alcoa-aluminum-Care-Free-Home-converted.pdf

3. Post-WW II prefab aluminum and steel houses in the UK

By the end of WW II in Europe (V-E Day is 8 May 1945), the UK faced a severe housing shortage as their military forces returned home to a country that had lost about 450,000 homes to wartime damage.

On 26 March 1944, Winston Churchill made an important speech promising that the UK would manufacture 500,000 prefabricated homes to address the impending housing shortage. Later in the year, the Parliament passed the Housing (Temporary Accommodation) Act, 1944, charging the Ministry of Reconstruction with developing solutions for the impending housing shortage and delivering 300,000 units within 10 years, with a budget of £150 million.

The Act provided several strategies, including the construction of temporary, prefabricated housing with a planned life of up to 10 years. The Temporary Housing Program (THP) was officially known as the Emergency Factory Made (EFM) housing program. Common standards developed by the Ministry of Works (MoW) required that all EFM prefabricated units have certain characteristics, including:

- Minimum floor space of 635 square feet (59 m2)

- Maximum width of prefabricated modules of 7.5 feet (2.3 m) to enable transportation by road throughout the country

- Implement the MoW’s concept of a “service unit,” which placed the kitchen and bathroom back-to-back to simplify routing plumbing and electrical lines and to facilitate factory manufacture of the unit.

- Factory painted, with “magnolia” (yellow-white) as the primary color and gloss green as the trim color.

In 1944, the UK Ministry of Works held a public display at the Tate Gallery in London of five types of prefabricated temporary houses.

- The original Portal all-steel prototype bungalow

- The AIROH (Aircraft Industries Research Organization on Housing) aluminum bungalow, made from surplus aircraft material.

- The Arcon steel-framed bungalow with asbestos concrete panels. This deign was adapted from the all-steel Portal prototype.

- Two timber-framed prefab designs, the Tarran and the Uni-Seco

This popular display was held again in 1945 in London.

Supply chain issues slowed the start of the EFM program. The all-steel Portal was abandoned in August 1945 due to a steel shortage. In mid-1946, a wood shortage affected other prefab manufacturers. Both the AIROH and Arcon prefab houses were faced with unexpected manufacturing and construction cost increases, making these temporary bungalows more expensive to build than conventionally constructed wood and brick houses.

Under a Lend-Lease Program announced in February 1945, the US agreed to supply the UK with US-built, wood frame prefabricated bungalows known as the UK 100. The initial offer was for 30,000 units, which subsequently was reduced to 8,000. This Lend-Lease agreement came to an end in August 1945 as the UK started to ramp up its own production of prefabricated houses. The first US-built UK 100 prefabs arrived in late May/early June 1945.

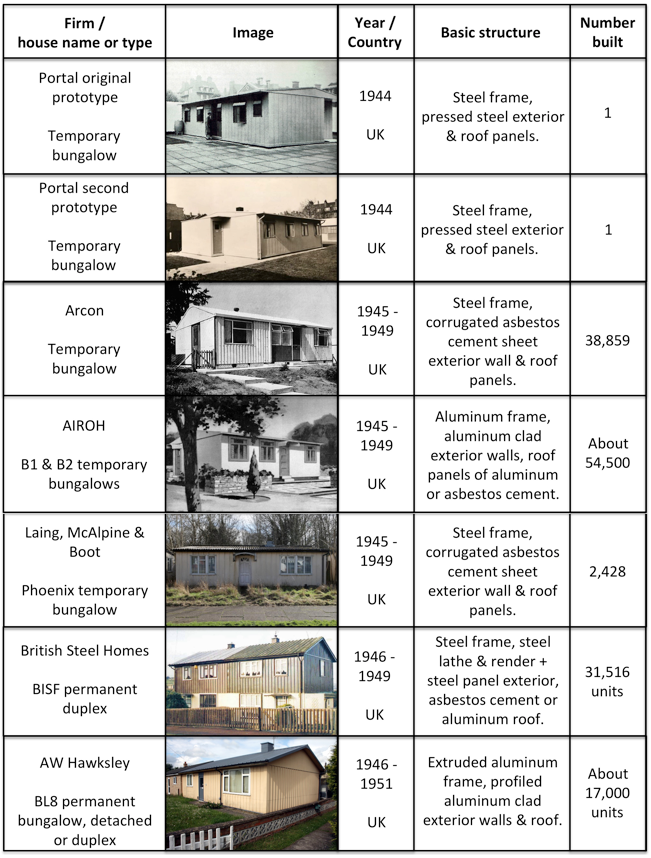

The UK’s post-war housing reconstruction program was quite successful, delivering about 1.2 million new houses between 1945 and 1951. During this reconstruction period, 156,623 temporary prefabricated homes of all types were delivered under the EFM program, which ended in 1949, providing housing for about a half million people. Over 92,800 of these were temporary aluminum and steel bungalows. The AIROH aluminum bungalow was the most popular EFM model, followed by the Arcon steel frame bungalow and then the wood frame Uni-Seco. In addition, more than 48,000 permanent aluminum and steel prefabricated houses were built by AW Hawksley and BISF during that period.

In comparison to the very small number of post-war aluminum and steel prefabricated houses built in the US, the post-war production of aluminum and steel prefabs in the UK was very successful.

UK post-WW II prefabricated aluminum and steel houses

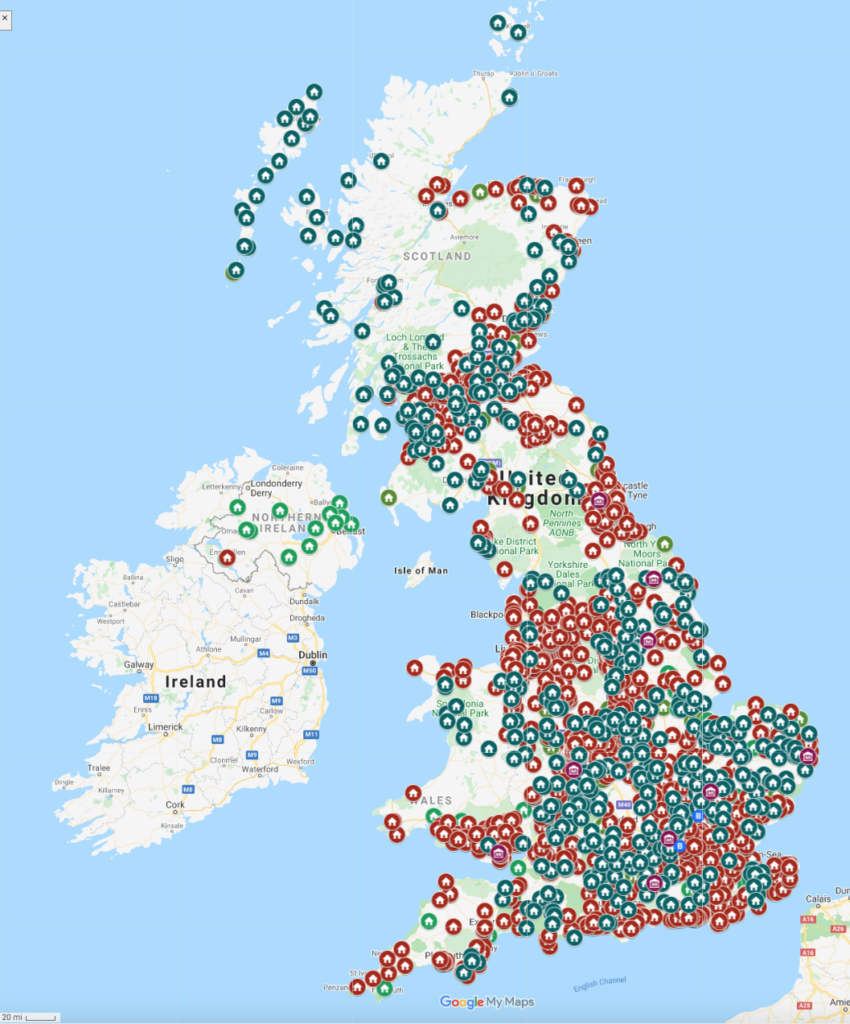

In a 25 June 2018 article in the Manchester Evening News, author Chris Osuh reported that, “It’s thought that between 6 or 7,000 of the post-war prefabs remain in the UK…..” The Prefab Museum maintains a consolidated interactive map of known post-WW II prefab house locations in the UK at the following link: https://www.prefabmuseum.uk/content/history/map

In the UK, Grade II status means that a structure is nationally important and of special interest. Only a few post-war temporary prefabs have been granted the status as Grade II listed properties:

- In an estate of Phoenix steel frame bungalows built in 1945 on Wake Green Road, Moseley, Birmingham, 16 of 17 homes were granted Grade II status in 1998.

- Six Uni-Seco wood frame bungalows built in 1945 – 46 in the Excalibur Estate, Lewisham, London were granted Grade II status in 2009. At that time, Excalibur Estates had the largest number of WW II prefabs in the UK: 187 total, of several types.

Several post-war temporary prefabs are preserved at museums in the UK and are available to visit.

- St. Fagans National Museum of History in Cardiff, South Wales: An AIROH B2 originally built near Cardiff in 1947 was dismantled and moved to its current museum site in 1998 and opened to the public in 2001. You can see this AIROH B2 here: https://museum.wales/stfagans/buildings/prefab/

- Avoncroft Museum of Historic Buildings in Stoke Heath, Bromsgrove, Worcestershire: You can see a 1946 Arcon Mk V here: https://avoncroft.org.uk/avoncrofts-work/historic-buildings/

- Rural Life Living Museum in Tilford, Farnham, Surrey: Their exhibits include an Arcon Mk V here: https://rural-life.org.uk/explore-discover/our-exhibits/

- Chiltern Open Air Museum (COAM) in Chalfont St. Giles, Buckinghamshire: Their collection includes a wood frame Universal House Mark 3 prefab manufactured by Universal Housing Company of Rickmansworth, Hertfordshire. This prefab was built in 1947 in the Finch Lane Estate in Amersham. You can see the “Amersham Prefab” here: https://www.coam.org.uk/museum-buckinghamshire/historic-buildings/amersham-prefab/

- Imperial War Museum in Duxford, Cambridgeshire: The collection includes a Uni-Seco wood frame prefab that was relocated from London: https://www.iwm.org.uk/collections/item/object/30084361

I think the Prefab Museum is best source for information on UK post-WW II prefabs. When it was created in March 2014 by Elisabeth Blanchet (author of several books and articles on UK prefabs) and Jane Hearn, the Prefab Museum had its home in a vacant prefab on the Excalibur Estate in south London. After a fire in October 2014, the physical museum closed but has continued its mission to collect and record memories, photographs and memorabilia, which are presented online via the Prefab Museum’s website at the following link: https://www.prefabmuseum.uk

You’ll find more information in my articles on specific UK post-WW II prefabricated aluminum and steel houses at the following links:

- Portal steel prototype temporary bungalows: https://lynceans.org/wp-content/uploads/2020/06/Portal-steel-bungalow-converted.pdf

- Arcon steel frame temporary bungalows: https://lynceans.org/wp-content/uploads/2020/06/Arcon-steel-frame-bungalow-converted.pdf

- AIROH aluminum temporary bungalows: https://lynceans.org/wp-content/uploads/2020/06/AIROH-aluminum-bungalow-converted.pdf

- Phoenix steel frame temporary bungalows: https://lynceans.org/wp-content/uploads/2020/06/Phoenix-steel-frame-bungalow-converted.pdf

- BISF steel frame permanent duplex houses: https://lynceans.org/wp-content/uploads/2020/06/British-Iron-Steel-Federation-BISF-house-converted.pdf

- AW Hawksley aluminum permanent houses: https://lynceans.org/wp-content/uploads/2020/06/AW-Hawksley-aluminum-bungalow-converted.pdf

4. Post-WW II prefab aluminum and steel houses in France

At the end of WW II, France, like the UK, had a severe housing shortage due to the great number of houses and apartments damaged or destroyed during the war years, the lack of new construction during that period, and material shortages to support new construction after the war.

To help relieve some of the housing shortage in 1945, the French Reconstruction and Urbanism Minister, Jean Monnet, purchased the 8,000 UK 100 prefabricated houses that the UK had acquired from the US under a Lend-Lease agreement. These were erected in the Hauts de France (near Belgium), Normandy and Brittany, where many are still in use today.

The Ministry of Reconstruction and Town Planning established requirements for temporary housing for people displaced by the war. Among the initial solutions sought were prefabricated dwellings measuring 6 x 6 meters (19.6 x 19.6 feet); later enlarged to 6 × 9 meters (19.6 x 29.5 feet).

About 154,000 temporary houses (the French called then “baraques”), in many different designs, were erected in France in the post-war years, primarily in the north-west of France from Dunkirk to Saint-Nazaire. Many were imported from Sweden, Finland, Switzerland, Austria and Canada.

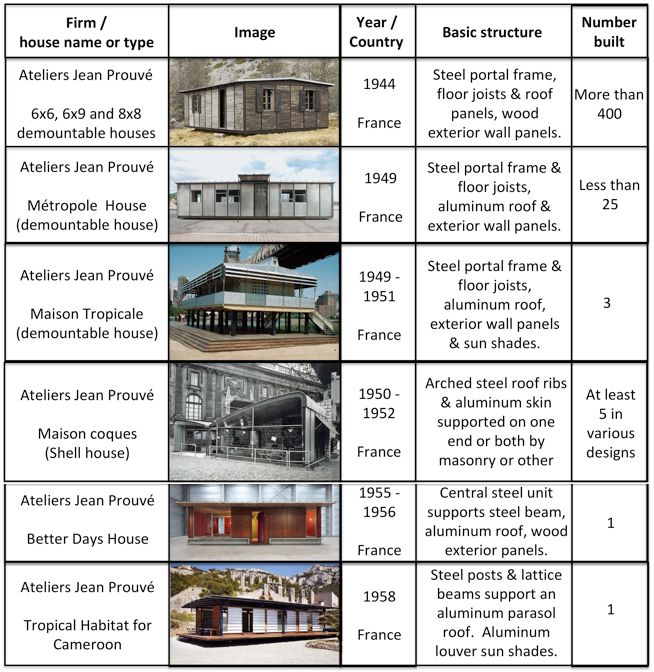

The primary proponent of French domestic prefabricated aluminum and steel house manufacturing was Jean Prouvé, who offered a novel solution for a “demountable house,” which could be easily erected and later “demounted” and moved elsewhere if needed. A steel gantry-like “portal frame” was the load-bearing structure of the house, with the roof usually made of aluminum, and the exterior panels made of wood, aluminum or composite material. Many of these were manufactured in the size ranges requested by Ministry of Reconstruction. During a visit to Prouvé’s Maxéville workshop in 1949, Eugène Claudius-Petit, then the Minister of Reconstruction and Urbanism, expressed his determination to encourage the industrial production of “newly conceived (prefabricated) economical housing.”

French post-WW II prefabricated aluminum and steel houses

Today, many of Prouvé’s demountable aluminum and steel houses are preserved by architecture and art collectors Patrick Seguin (Galerie Patrick Seguin) and Éric Touchaleaume (Galerie 54 and la Friche l’Escalette). Ten of Prouvé’s Standard Houses and four of his Maison coques-style houses built between 1949 – 1952 are residences in the small development known as Cité “Sans souci,” in the Paris suburbs of Muedon.

Prouvé’s 1954 personal residence and his relocated 1946 workshop are open to visitors from the first weekend in June to the last weekend in September in Nancy, France. The Musée des Beaux-Arts de Nancy has one of the largest public collections of objects made by Prouvé.

Author Elisabeth Blanchet reports that the museum “Mémoire de Soye has managed to rebuild three different ‘baraques’: a UK 100, a French one and a Canadian one. They are refurbished with furniture from the war and immediate post-war era. Mémoire de Soye is the only museum in France where you can visit post-war prefabs.” The museum is located in Lorient, Brittany. Their website (in French) is here: http://www.soye.org

You’ll find more information on French post-WW II prefabricated aluminum and steel houses in my article on Jean Prouvé’s demountable houses at the following link: https://lynceans.org/wp-content/uploads/2020/06/Jean-Prouvé-demountable-houses-converted.pdf

5. In conclusion

In the U.S., the post-war mass production of prefabricated aluminum and steel houses never materialized. Lustron was the largest manufacturer with 2,498 houses. In the UK, over 92,800 prefabricated aluminum and steel temporary bungalows were built as part of the post-war building boom that delivered a total of 156,623 prefabricated temporary houses of all types between 1945 and 1949, when the program ended. In France, hundreds of prefabricated aluminum and steel houses were built after WW II, with many being used initially as temporary housing for people displaced by the war. Opportunities for mass production of such houses did not develop in France.

The lack of success in the U.S. arose from several factors, including:

- High up-front cost to establish a mass-production line for prefabricated housing, even in a big, surplus wartime factory that was available to the house manufacturer on good financial terms.

- Immature supply chain to support a house manufacturing factory (i.e., different suppliers are needed than for the former aircraft factory).

- Ineffective sales, distribution and delivery infrastructure for the manufactured houses.

- Diverse, unprepared local building codes and zoning ordnances stood in the way of siting and erecting standard design, non-conventional prefab homes.

- Opposition from construction unions and workers that did not want to lose work to factory-produced homes.

- Only one manufacturer, Lustron, produced prefab houses in significant numbers and potentially benefitted from the economics of mass production. The other manufacturers produced in such small quantities that they could not make the transition from artisanal production to mass production.

- Manufacturing cost increases reduced or eliminated the initial price advantage predicted for the prefabricated aluminum and steel houses, even for Lustron. They could not compete on price with comparable conventionally constructed houses.

- In Lustron’s case, charges of corporate corruption led the Reconstruction Finance Corporation to foreclose on Lustron’s loans, forcing the firm into an early bankruptcy.

From these post-WW II lessons learned, and with the renewed interest in “tiny homes”, it seems that there should be a business case for a modern, scalable, smart factory for the low-cost mass-production of durable prefabricated houses manufactured from aluminum, steel, and/or other materials. These prefabricated houses could be modestly-sized, modern, attractive, energy efficient (LEED-certified), and customizable to a degree while respecting a basic standard design. These houses should be designed for mass production and siting on small lots in urban and suburban areas. I believe that there is a large market in the U.S. for this type of low-price housing, particularly as a means to address the chronic affordable housing shortages in many urban and suburban areas. However, there still are great obstacles to be overcome, especially where construction industry labor unions are likely to stand in the way and, in California, where nobody will want a modest prefabricated house sited next to their McMansion.

You can download a pdf copy of this post, not including the individual articles, here:

6. For additional information

US post-WW II housing crisis and prefabricated homes:

- Construction in the War Years – 1942 – 45, US Department of Labor, Bureau of Labor Statistics, Bulletin No. 915: https://fraser.stlouisfed.org/files/docs/publications/bls/bls_0915_1948.pdf

- Hartley Howe, “Stopgap Housing,” Popular Science, pp. 66-71, March 1946: https://books.google.com/books?id=PSEDAAAAMBAJ&printsec=frontcover&source=gbs_ge_summary_r&cad=0#v=onepage&q&f=false

- William Remington, “The Veterans Emergency Housing Program,” Law and Contemporary Problems, December 1946: https://scholarship.law.duke.edu/cgi/viewcontent.cgi?article=2295&context=lcp

- “Veterans Emergency Housing Report,” National Housing Agency, Office of the Housing Expediter, Vol. 1, Nos. 2 to 8, July 1946 to January 1947, available to read online via Google Books: https://play.google.com/books/reader?id=Q_jjCy0570QC&hl=en&pg=GBS.RA1-PA1

- Blaine Stubblefield, “Aircraft Industry Will Make Aluminum Houses for Veterans,” Aviation News, Vol. 6, No. 10, 2 September 1946 (available in the Aviation Week & Space Technology magazine online archive)

- “Battle for Aluminum Discounted by NHA,” Aviation News magazine, p. 22, 14 October 1946 (available in the Aviation Week & Space Technology magazine online archive)

- Ante Lee (A. L.) Carr, “A Practical Guide to Prefabricated Houses”, Harper & Brothers, 1947, available online in text via the Internet Archive at the following link: https://archive.org/stream/ALCarrApracticalguidetoprefabricatedhouses0001/ALCarrApracticalguidetoprefabricatedhouses0001_djvu.txt

- Burnham Kelly, “The Prefabrication of Houses – A Study by the Albert Farwell Bemis Foundation of the Prefabrication Industry in the United States,” Technology Press of MIT and John Wiley & Sons, 1951: http://www.survivorlibrary.com/library/the_prefabrication_of_houses_1951.pdf

- “Catalogue of House Building Construction Systems,” Central Mortgage and Housing Corporation, Ottawa, Canada,1960: https://dahp.wa.gov/sites/default/files/Catalogue_of_House_Building_Construction_Systems_1960_0.pdf

- Keller Easterling and Richard Prelinger, “Call it Home: The House That Private Enterprise Built,” The Voyager Company 1992: http://www.columbia.edu/cu/gsapp/projs/call-it-home/html/

UK post-WW II housing crisis and prefabricated home:

- Elisabeth Blanchet, “Prefab Homes,” Shire Library (Book 788), 21 October 2014, ISBN-13: 978-0747813576

- Elisabeth Blanchet, “A Fond Farewell to Britain’s Prefab WWII Bungalows,” Atlas Obscure, 26 April 2017: https://www.atlasobscura.com/articles/excalibur-estate-prefab-homes

- Elisabeth Blanchet, Sonia Zhuravlyova, “Prefabs – A social and architectural history, “ Historic England, 15 September 2018, ISBN-13: 978-1848023512

- Jane Hearn, “The Prefab Museum Education Pack – Post War Prefabs,” The Prefab Museum, 2018: https://www.prefabmuseum.uk/content/history/education-pack-2

- Chris Osuh, “Return of the prefab: Could ‘flat-pack’ homes solve Manchester’s housing crisis?,” Manchester Evening News, 25 June 2018: https://www.manchestereveningnews.co.uk/news/greater-manchester-news/return-prefab-could-flat-pack-14818763

- “Prefabs in the United Kingdom,” 12 April 2018: https://wikiaboutdoll.blogspot.com/2018/04/prefabs-in-united-kingdom.html

- “Prefabulous,” Historic England and Google Arts & Culture, https://artsandculture.google.com/exhibit/1QLyNUcHxjFSIA

- “The History of Council Housing,” Section 3, “Meeting the Post-war Housing Shortage,” University of the West of England, Bristol, UK: http://fet.uwe.ac.uk/conweb/house_ages/council_housing/print.htm

French post-WW II housing crisis and prefabricated homes:

- Elisabeth Blanchet, “Prefabs in France,” Prefab Museum (UK), 2016: https://www.prefabmuseum.uk/content/history/prefabs-in-france

- Nicole C. Rudolph, “At Home in Postwar France – Modern Mass Housing and the Right to Comfort,” Berghahn Monographs in French Studies (Book 14), Berghahn Books, March 2015, ISBN-13: 978-1782385875. The introduction to this book is available online at the following link: https://berghahnbooks.com/downloads/intros/RudolphAt_intro.pdf

- Kenny Cupers, “The Social Project: Housing Postwar France,” University Of Minnesota Press, May 2014, ISBN-13: 978-0816689651