Peter Lobner, updated 18 October 2024 (post-Rev. 6)

1. Introduction

Modern Airships is a three-part document that contains an overview of modern airship and aerostat technology in Part 1 and links in Parts 1, 2 and 3 to more than 275 individual articles on historic and advanced airship designs. This is Part 1. Here are the links to the other two parts:

- Modern Airships – Part 2: https://lynceans.org/all-posts/modern-airships-part-2/

- Modern Airships – Part 3: https://lynceans.org/all-posts/modern-airships-part-3/

To help you navigate the large volume of material in these three documents, please refer to following indexes. The first index simply lists the article titles in alphabetic order within each Part.

Parts 1 & 2 address similar types of airships and unpowered aerostats. The following airship type index enables you to see all of the airships and aerostats addressed in Parts 1 & 2, grouped by type, with direct links to the relevant articles.

The airships described in Part 3 are relatively exotic concepts in comparison to the more utilitarian and heavy-lift airships that dominate Parts 1 and 2. As shown in the following index, the airships in Part 3 are organized by function rather than airship type, which sometimes is difficult to determine with the information available.

Modern Airships – Part 1 begins with an overview of modern airship and aerostat technology, continues with a graphic table that identifies the airships addressed in this part, and concludes by providing links to more than 100 individual articles on these airships. A downloadable pdf copy of Part 1 is available here:

If you have any comments or wish to identify errors in this document, please send me an e-mail to: [email protected].

I hope you’ll find the Modern Airships series to be informative, useful, and different from any other single document on this subject.

Best regards,

Peter Lobner

18 October 2024

Record of revisions to Part 1

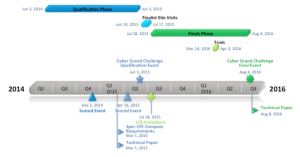

- Original Modern Airships post, 26 August 2016: addressed 14 airships in a single post.

- Expanded the Modern Airships post and split it into three parts, 18 August 2019: Part 1 included 22 linked articles.

- Part 1, Revision 1, 21 December 2020: Added 15 new articles, split the existing Aeros article into two articles and updated all of the original articles. Part 1 now had 38 articles.

- Part 1, Revision 2, 3 April 2021: Updated the main text and 10 existing articles, and expanded and reorganized the graphic tables. Part 1 still had 38 articles

- Part 1, Revision 3, 26 August 2021: Added 34 new articles, split the existing Helistat article into five articles and the Aereon article into two articles, and expanded and reorganized the graphic tables. Also updated 23 existing articles. Part 1 now had 77 articles.

- Part 1, Revision 4, 12 February 2022: Added 12 new articles, split the existing Airlander article into two updated articles (prototype, production), moved Halo to Part 3, expanded the graphic tables and updated 17 additional existing articles. A detailed summary of changes incorporated in Part 1 Rev 4 is listed here. Part 1 now had 89 articles.

- Part 1, Revision 5, 10 March 2022: Added 2 new articles, split rigid & semi-rigid airships in the graphic tables, and updated 58 existing articles. With this revision, all Part 1 linked articles have been updated in February or March 2022. A detailed summary of changes incorporated in Part 1 Rev 5 is listed here. Part 1 now has 91 articles.

- Part 1, Revision 6, 17 March 2024: This revision includes a major reorganization of Parts 1 & 2 to better aggregate airships and unpowered aerostats by type, with a corresponding reorganization of the graphic tables. Over the past two years, 15 new articles were added to Part 1 and 28 articles were updated. In the final changes for Rev. 6, several articles were moved between Parts 1 & 2. A detailed summary of changes incorporated in Part 1 Rev 6 is listed here. Part 1 now has 107 articles.

Part 1, changes since Rev. 6 (17 March 2024)

New articles:

- None yet

Updated articles:

- LTA Research and Exploration – 8 July 2024

- AT2 Aerospace – 17 September 2024

- Lockheed Martin – P-791 – 30 September 2024

- Lockheed Martin – Sky Tug and LMH-1 – 30 September 2024

- Hybrid Air Vehicles (HAV) / Northrop Grumman – HAV-3 and HAV-304 (LEMV) – 2 October 2024

- Hybrid Air Vehicles (HAV) – Airlander 10 prototype – 2 October 2024

- Walden Aerospace / LTAS / LTASI – Lenticular, toroidal, variable buoyancy airships – 18 October 2024

2. Well-established benefits and opportunities, but a risk-averse market

For several decades, there has been significant interest in the use of modern lighter-than-air craft and hybrid airships in a variety of military, commercial and other roles, including:

- Heavy cargo carriers operating point-to-point between manufacturer and end-user, eliminating inter-modal load transfers enroute

- Heavy cargo carriers serving remote and/or unimproved sites not adequately served by other modes of transportation

- Disaster relief, particularly in areas not easily accessible by other means

- Persistent optionally-manned surveillance platforms for military intelligence, surveillance & reconnaissance (ISR), maritime surveillance, border patrol, search and rescue

- Passenger airships

- Commercial flying cruise liner / flying hotel

- Airship yacht

- Personal airship

- Drone carrier

- High altitude regional communications node

One of the very significant factors driving interest in modern airships is that they offer the potential to link isolated regions with the rest of the world while doing so in a way that should have lower environmental impacts than other transportation alternatives for those regions. This target market for airships exists in more than two-thirds of the world’s land area where more than half the world’s population live without direct access to paved roads and reliable ground transportation.

This matter is described well in a 21 February 2016 article by Jeanne Marie Laskas, “Helium Dreams – A new generation of airships is born,” which is posted on The New Yorker website at the following link: https://www.newyorker.com/magazine/2016/02/29/a-new-generation-of-airships-is-born

In spite of the significant interest and the development of many promising airship designs, an actual worldwide airship cargo and passenger transportation industry has been very slow in developing. To give you an example of how slow:

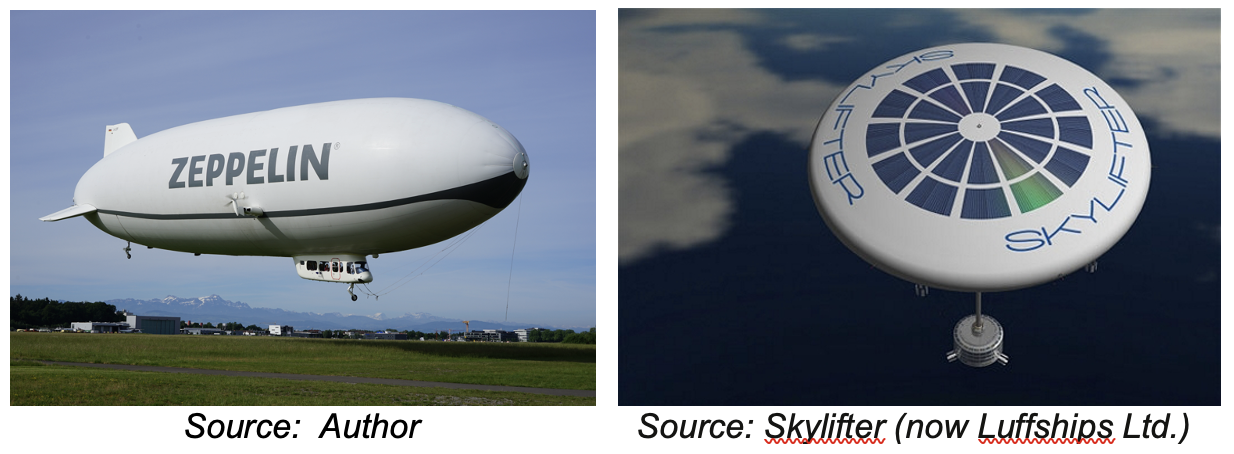

- As of November 2023, other than a modest number of commercially certified blimps used largely as advertising platforms, the Zeppelin NT 07 is the only advanced airship that has been certified and is flying regularly in commercial passenger service.

- At the March 2019 Aviation Innovations Conference – Cargo Airships in Toronto, Canada, Solar Ship CEO Jay Godsall proposed an industry-wide challenge to actually demonstrate by July 2021 airships that can move a 3 metric ton (6,614 lb) standard 20 foot intermodal container configured as a mobile medical lab 300 km (186 mi) to a remote location. Godsall noted that this capability would be of great value if it did exist, for example, in support of relief efforts in Africa and other regions of the world.

So in spite of the airship industry having developed many designs capable of transporting 10’s to 100’s of tons of cargo thousands of miles, today there is not a single airship than can transport a 3 metric ton (6,614 lb) payload 300 km (186 mi).

Why has the airship industry been so slow to develop? The bottom line has been a persistent lack of funding. With many manufacturers having invested in developing advanced designs in varying levels of detail, the first to secure adequate funding will be able to take the next steps to build and certify a manufacturing facility, build and flight test a full-scale prototype airship, complete the airship type certification process, and start offering a certified airship for sale.

There are some significant roadblocks in the way:

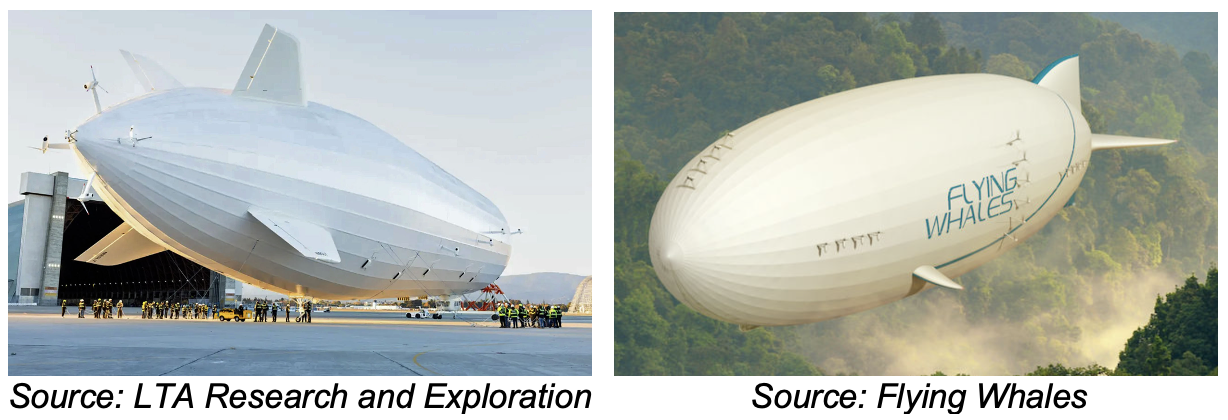

- No full-scale prototypes are flying: Many airship firms currently have little more than slide presentations to show to potential investors and customers. There are few sub-scale airship demonstrators, but no full-scale prototypes. The airship firms are depending on potential investors and customers making a “leap of faith” that the “paper” airship actually can be delivered. However, this situation will change significantly in the next few years as several airship manufacturers (i.e., LTA Research and Exploration, Flying Whales and Hybrid Air Vehicles) finally complete their full-scale, large airship prototypes and commence flight testing.

- Immature manufacturing capability: While the airship industry has been good at developing many advanced designs, some claiming to exist as “construction-ready” plans, few airship firms are in the process of building an airship factory. The industrial scale-up factor for an airship firm to go from the design and engineering facilities existing today to the facilities needed for series production of full-scale airships is huge. LTA Research and Exploration is one of the few firms with access to modernized large airship hangars (the former Goodyear Airdock in Akron OH and the former Navy airship hangars at Moffett Field, CA) for use as manufacturing facilities. In 2016, Russian airship manufacturer Augur RosAeroSystems proposed building a new factory to manufacture up to 10 ATLANT airships per year. The funding requirement for that factory was estimated at $157 million. The exact amount isn’t important. No matter how you look at it, it’s a big number. Large investments are needed for any airship firm to become a viable manufacturer.

- Significant financial risk: The amount of funding needed by airship firms to make the next steps toward becoming a viable manufacturer exceeds the amount available from venture capitalists who are willing to accept significant risk. Private equity sources typically are risk averse. Public sources, or public-private partnerships, have been slow to develop an interest in the airship industry. The French airship firm Flying Whales appears to be the first to have gained access to significant funding from public institutions.

- Significant regulatory risk: Current US, Canadian and European airship regulations were developed for non-rigid blimps and they fail to address how to certify most of the advanced airships currently under development. This means that the first airship manufacturers seeking type certificates for advanced airships will face uphill battles as they have to deal with aviation regulatory authorities struggling to fill in the big gaps in their regulatory framework and set precedents for later applicants. It is incumbent on the aviation regulatory authorities to get updated regulations in place in a timely manner and make the regulatory process predictable for existing and future applicants.

- No airship operational infrastructure: There is nothing existing today that is intended to support the operation of new commercial airships tomorrow. The early airship operators will need to develop operating bases, hangar facilities, maintenance facilities, airship routes, and commercial arrangements for cargo and passengers. While many airship manufacturers boast that their designs can operate from unimproved sites without most or all of the traditional ground infrastructure required by zeppelins and blimps, the fact of the matter is that not all advanced airships will be operating from dirt fields and parked outside when not flying. There is real infrastructure to be built, and this will require a significant investment by the airship operators.

- Steep learning curve for potential customers: Only the operators of the Zeppelin NT have experience in operating a modern airship today. The process for integrating airship operations and maintenance into a customer’s business work flow has more than a few unknowns. With the lack of modern airship operational experience, there are no testimonials or help lines to support a new customer. They’ll have to work out the details with only limited support. Ten years from now, the situation should be vastly improved, but for the first operators, it will be a challenge.

- Few qualified pilots and crew: The airship manufacturers will need to work with the aviation regulatory authorities and develop programs for training and licensing new pilots and crew. The British airship manufacturer Varialift has stated that one of the roles of their ARH-PT prototype will be to train future pilots.

This uncertain business climate for airships seems likely to change in the mid-to-late 2020s, when several different heavy-lift and passenger airships are expected to be certified by airworthiness authorities and ready for series production and sale to interested customers. If customers step up and place significant orders, we may be able to realize the promise of airship travel and its potential to change our world in many positive ways.

3. Status of current aviation regulations for airships

As noted previously, current aviation regulations have not kept pace with the development of modern airship technology. In this section, we’ll take a look at the current regulations.

US Federal Aviation Administration (FAA)

In the US, the FAA’s current requirements for airships are defined in the document FAA-P-8110-2, Change 2, “Airship Design Criteria (ADC),” dated 6 February 1995, which is available here:

The ADC applies to non-rigid, near-equilibrium, conventional airships with seating for nine passengers or less, excluding the pilot, and it serves as the basis for issuing the type certificate required before a particular airship type can enter commercial service in the US. The limited scope of this current regulation is highlighted by the following definitions contained in the ADC:

- Airship: an engine-driven, lighter-than-air aircraft, than can be steered.

- Non-rigid: an airship whose structural integrity and shape is maintained by the pressure of the gas contained within the envelope.

- Near-equilibrium: an airship that is capable of achieving zero static heaviness during normal flight operations.

Supplementary guidance for non-rigid, near-equilibrium, conventional airships is provided in FAA Advisory Circular (AC) No. 21.17-1A, “Type Certification – Airships,” dated 25 September 1992, which is available here:

https://www.faa.gov/documentlibrary/media/advisory_circular/ac_21-17-1a.pdf

The FAA’s ADC and the associated AC were written for blimps, not for the range of modern airships under development today. For example, aerostatic lift is only one component of lift in modern hybrid airships, which also depend on powered lift from engines and aerodynamic lift during forward flight. Hybrid airships are not “lighter-than-air” and cannot achieve zero static heaviness during normal operations, yet they are an important class of airships being developed in several countries. In addition, almost all modern airships, except blimps, have rigid or semi-rigid structures that enable them to carry heavy loads and mount powerful engines on locations other than the gondola of a non-rigid airship.

On March 12, 2012 the FAA announced that Lockheed Martin Aeronautics submitted an application for type certification for their model LMZ1M (LMH-1), which is “a manned cargo lifting hybrid airship incorporating a number of advanced features.” The FAA assigned that application to their docket number FAA-2013-0550.

To address the gap in airship regulations head-on, Lockheed Martin submitted to the FAA their recommended criteria document, “Hybrid Certification Criteria (HCC) for Transport Category Hybrid Airships,” which is a 206 page document developed specifically for the LMZ1M (LMH-1). The HCC is also known as Lockheed Martin Aeronautics Company Document Number 1008D0122, Rev. C, dated 31 January 2013. You can download the HCC document and related public docketed items on the FAA website here:

https://www.regulations.gov/docket/FAA-2013-0550/document

In November 2015, Lockheed Martin announced that the FAA’s Seattle Aircraft Certification Office had approved the project-specific certification plan for the LMZ1M (LMH-1). At the time Lockheed Martin transitioned their hybrid airship business to AT2 Aerospace in May 2023, their hybrid airship had not yet been type certified.

Germany & Netherlands

Recognizing the absence of an adequate regulatory framework for modern airships, civil aviation authorities of Germany and Netherlands developed supplementary guidance to the European Joint Aviation Requirements (JAR-25) and the FAA’s ADC for a category of airships called “Transport Airships,” which they define as follows:

“The transport category is defined for multi-engine propeller driven airships that have a capacity of 20 or more passengers (excluding crew), or a maximum take-off mass of 15,000 kg or more, or a design lifting gas volume of 20,000 m3 or more, whichever is greater.”

These supplementary requirements are contained in the document “Transport Airship Requirements” (TAR), dated March 2000, which you will find at the following link: https://www.faa.gov/aircraft/air_cert/design_approvals/airships/airships_regs/media/aceAirshipTARIssue1.pdf

European Union Aviation Safety Agency (EASA)

On 11 February 2021, the European Union Aviation Safety Agency (EASA) proposed a new regulatory framework for the certification of large airships. The proposed document went through a public review and comment period before the final document was issued on 21 January 2022 as Doc. No. SC GAS, “Special Condition ‘SC GAS’ Gas Airships,” which is available here: https://www.easa.europa.eu/downloads/134946/en

EASA explained their rationale for this special condition document:

“EASA has received applications for the type certification of large Airships but has not yet published Certification Specifications (CS) for these products…… In the absence of agreed and published certification specifications for Airships by EASA…….a complete set of dedicated technical specifications in the form of a Special Condition for Gas Airships has been developed. This Special Condition addresses the unique characteristics of Airships and defines airworthiness specifications that may be used to demonstrate compliance with the essential requirements in Annex II of regulation (EU) 2018/1139 of the European Parliament and Council. That is required before the issuance of the EASA type certificate, as well as for the approval of later changes to type certificate.”

“The Special Condition is a high-level set of objective driven and performance-based requirements. It was developed in close cooperation with the industry working group. The Special Condition addresses two designs, one being a 260,000 m3 rigid equilibrium Airship for cargo operations, the other one a 45,000 m3 non-rigid hybrid Airship for up to 100 passengers. However, the authors believe the SC can be applied to all manned Airships with non-pressurized crew or passenger compartments. It will be subject to EASA Certification Team agreement whether this Special Condition can be deemed sufficient as a Certification Basis, for example unmanned designs are not sufficiently addressed by this proposal. Due to the low number of projects no categories have been established. The different safety levels applicable to specific Airship designs will be addressed through the Means of Compliance (MOC).”

The EASA is ahead of the FAA in terms of having published usable interim regulations for advanced airships. However, both EASA and FAA regulators are lagging the development of advanced civilian airship designs that may be submitted for type certification in the next decade. The lack of mature regulations for advanced airship designs will increase the regulatory risk for the designers / manufacturers of those airships.

4. Lifting gas

In the US, Europe and Canada, the following aviation regulations only allow the use of non-flammable lifting gas:

- FAA ADC: “The lifting gas must be non-flammable.” (4.48)

- TAR: “The lifting gas must be non-flammable, non-toxic and non-irritant.” (TAR 893)

- Canadian Air Regulations: “Hydrogen is not an acceptable lifting gas for use in airships.” (541.7)

The EASA proposed Special Condition issued on 21 January 2022 creates an opportunity to use flammable lifting gases, subject to the following conditions:

- SC GAS.2355 Lifting gas system

- Lifting gas systems required for the safe operation of the Airship must:

- withstand all loading conditions expected in operation including emergency conditions

- monitor and control lifting performance and degradation

- If the lifting gas is toxic, irritant or flammable, adequate measures must be taken in design and operation to ensure the safety of the occupants and people on the ground in all envisaged ground and flight conditions including emergency conditions.

- Lifting gas systems required for the safe operation of the Airship must:

- SC GAS.2340 Electrostatic Discharge

- There must be appropriate electrostatic discharge means in the design of each Airship whose lift-producing medium contains a flammable gas to ensure that the effects of electrostatic discharge will not create a hazard.

- SC GAS.2325 Fire Protection

- The design must minimize the risk of fire initiation caused by:

- Anticipated heat or energy dissipation or system failures or overheat that are expected to generate heat sufficient to ignite a fire;

- Ignition of flammable fluids, gases or vapors; and

- Fire propagating or initiating system characteristics (e.g. oxygen systems); and

- A survivable emergency landing.

- The design must minimize the risk of fire initiation caused by:

Without hydrogen, the remaining practical choices for lifting gas are helium and hot air. A given volume of hot air can lift only about one-third as much as the same volume of helium, making helium the near-universal choice, with hot air being relegated to a few, small thermal airships and larger thermal-gas (Rozière) airships.

The current high price of helium is a factor in the renewed interest in hydrogen as a lifting gas. It’s also a key selling point for thermal airships. Most helium is produced as a byproduct from natural gas production, hence, helium is not “rare.” However, only a very small fraction of helium available in natural gas currently is recovered, on the order of 1.25%. The remainder is released to the atmosphere. The helium recovery rate could be higher, but is not warranted by the current market for helium. Helium is difficult to store. The cost of transportation to end-users is a big fraction of the market price of helium.

Hydrogen provides 10% more lift than helium. It can be manufactured easily at low cost and can be stored. If needed, hydrogen can be produced with simple equipment in the field. This could be an important capability for recovering an airship damaged and grounded in a remote region. One airship concept described in Modern Airships – Part 3, the Aeromodeller II, is designed for using hydrogen as the lifting gas and as a clean fuel (zero greenhouse gases produced) for its propulsion engines. A unique feature of this airship concept is an on-board system to generate more hydrogen when needed from the electrolysis of water ballast.

A technique for preventing hydrogen flammability is described in Russian patent RU2441685C2, “Gas compound used to prevent inflammation and explosion of hydrogen-air mixtures,” which was filed in 2010 and granted in 2012. This technique appears to be applicable to an airship using hydrogen as its lifting gas. You can read the patent at the following link: https://patents.google.com/patent/RU2441685C2/en

The Canadian airship firm Buoyant Aircraft Systems International (BASI) is a proponent of using hydrogen lifting gas. Anticipating a future opportunity to use hydrogen, they have designed their lifting gas cells to be able to operate with either helium or hydrogen.

Additional regulatory changes will be required to permit the general use of hydrogen in aviation. With the growing interest in the use of hydrogen fuel in aviation, it seems only a matter of time before it is approved for use as a lifting gas in commercial airships.

Even with the needed regulatory changes, the insurance industry will have to deal with the matter of insuring a hydrogen-filled airship.

5. Types of modern airships and aerostats

The term “aerostat” broadly includes all lighter than air vehicles that gain lift through the use of a buoyant gas. Aerostats include unpowered balloons (tethered or free-flying) and powered airships. The following types of airships are described in the Modern Airships series of documents:

- Conventional airships

- Rigid airships

- Semi-rigid airships

- Non-rigid airships (blimps)

- Variable buoyancy airships

- Variable buoyancy, fixed volume airships

- Variable buoyancy, fixed volume, variable vacuum airships

- Variable buoyancy, variable volume airships

- Variable buoyancy, hybrid thermal-gas (Rozière) airships

- Variable buoyancy propulsion airships / aircraft

- Semi-buoyant hybrid air vehicles

- Semi-buoyant, hybrid airships

- Semi-buoyant, airplane / airship hybrids (Dynairship, Dynalifter, Megalifter)

- Semi-buoyant, helicopter / airship hybrids (helistats, Dynastats, rotostats)

- Stratospheric airships / High-Altitude Platform Stations (HAPS)

- Personal gas airships

- Thermal (hot air) airships

- Hybrid rocket / balloon (Rockoon) airships

- Electro-kinetically (EK) propelled airships

- LTA drones

- Unpowered aerostats

- Tethered aerostats (kite balloons)

- Tethered manned aerostats

- Tethered LTA wind turbines

- Tethered heavy lift balloons

- Hybrid tethered aerostat / free-flying powered airships

- Free-flying high-altitude balloons

- Free-flying manned high-altitude balloons

5.1 Conventional airships

Conventional airships are lighter-than-air (LTA) vehicles that operate at or near neutral buoyancy. The lifting gas (helium) generates approximately 100% of the lift at low speed, thereby permitting vertical takeoff and landing (VTOL) operations and hovering with little or no lift contribution from the propulsion / maneuvering system. Various types of propulsors may be used for cruise flight propulsion and for low-speed maneuvering and station keeping.

Airships of this type include rigid zeppelins, semi-rigid airships and non-rigid blimps.

- Rigid airships: These airships have a lightweight, rigid airframe with an outer skin that defines their exterior shape. The airframe supports the gondola, engines and payload. Most have atmospheric pressure lifting gas cells located within the rigid airframe. A special case is a metal-clad rigid airship, with a metal hull that is self-supporting at atmospheric pressure, but typically operates with a slightly positive internal pressure.

- Semi-rigid airships: These airships have a rigid structural framework (i.e., a keel or an internal framework) that supports loads and is connected via a load distribution system to a flexible, pressure-stabilized envelope that defines the exterior shape and typically contains air ballonets.

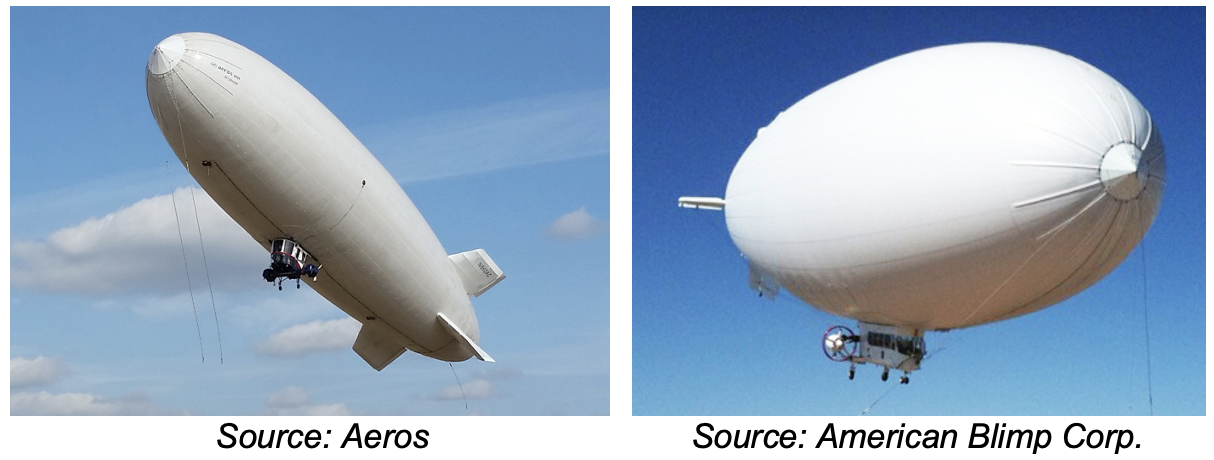

- Non-rigid airships (blimps): These airships have a pressure-stabilized, flexible envelope that defines the exterior shape of the airship and typically contains air ballonets. There is no keel or internal structure. Most loads are attached to the gondola and are transferred via a load distribution system to the envelope.

The LTA Research and Exploration Pathfinder 1 and the Flying Whales LCA60T are examples of conventional rigid airships.

The Zeppelin NT and the SkyLifter are examples of conventional semi-rigid airships.

The Aeros 40D Sky Dragon and the American Blimp Corporation MZ-3A (A-170G) are examples of conventional non-rigid airships (blimps).

After being loaded and ballasted before flight, conventional airships have various means to exercise in-flight control over their aerostatic buoyancy, internal pressure and trim. Buoyancy control is exercised with ballast and lifting gas. Internal pressure is controlled with air ballonets and lifting gas vents. Trim is adjusted with the air ballonets or moveable ballast.

Conventional airships with thrust vectoring propulsors have the ability to operate with some degree of net aerostatic heaviness or lightness that can be compensated for with the dynamic thrust (lift or downforce) from the adjustable propulsors.

Controlling buoyancy with ballast

Many conventional airships require adjustable ballast (i.e., typically water or sand) that can be added or removed as needed to establish a desired net buoyancy before flight. Load exchanges (i.e., taking on or discharging cargo or passengers) can change the overall mass of an airship and may require a corresponding ballast adjustment during or after the load exchange.

In-flight use of fuel and other consumables can change the overall mass of an airship. The primary combustion products of diesel fuel are water and carbon dioxide. To reduce the loss of mass from fuel consumption, some airships use a rather complex system to recover water from the engine exhaust. A modern diesel engine water recovery system being developed for the Aerovehicles AV-10 blimp is expected to recover 60% to 70% of the weight of the fuel burned, significantly reducing the change in airship mass during a long mission.

Some Navy blimps and other long-range airships have had a hoist system that could be used in flight to retrieve water from the ocean or any other body of water to increase the amount of on-board ballast.

If an airship becomes heavy, ballast can be dumped in flight to increase aerostatic buoyancy.

Controlling buoyancy with lifting gas

The lifting gas inside an airship may be at atmospheric pressure (most rigid airships) or at a pressure slightly greater than atmospheric (semi-rigid and non-rigid airships). Normally, there is no significant loss (leakage) of lifting gas to the environment. A given mass of lifting gas will create a constant lift force, regardless of pressure or altitude, when the lifting gas is at equal pressure and temperature with the surrounding air. Therefore, a change in altitude will not change the aerostatic lift.

However, temperature differentials between the lifting gas and the ambient air will affect the aerostatic lift produced by the lifting gas. To exploit this behavior, some airships can control buoyancy using lifting gas heaters / coolers to manage gas temperature.

The lifting gas heaters are important for operation in the Arctic, where a cold-soak in nighttime temperatures may result in the lifting gas temperature lagging behind daytime ambient air temperature. This temperature differential would result in a loss of lift until lifting gas and ambient air temperatures were equal.

Conversely, operating an airship in hot regions can result in the lifting gas temperature rising above ambient air temperature (the lifting gas becomes “superheated”), thereby increasing buoyancy. To restore buoyancy in this case, some airships have coolers (i.e., helium-to-air heat exchangers) in the lifting gas cells to remove heat from the lifting gas.

As described by Boyle’s Law, pressure (P) and gas volume (V) are inversely proportional at a constant temperature according to the following relationship: PV = K, where K is a constant. As an airship ascends, atmospheric pressure decreases. This means that a fixed mass of lifting gas will expand within the lifting gas cells during ascent, and will contract within the lifting gas cells during descent. As described previously, this lifting gas expansion and contraction does not affect the magnitude of the aerostatic lift as long as the lifting gas is at equal pressure and temperature with the surrounding air.

If an airship is light and the desired buoyancy cannot be restored with lifting gas coolers, it is possible to vent some lifting gas to the atmosphere to decrease aerostatic lift. Usually there are two types of vents: a manually-operated vent controlled by the pilot and an automatically-operated safety vent designed to protect the envelope from overpressure.

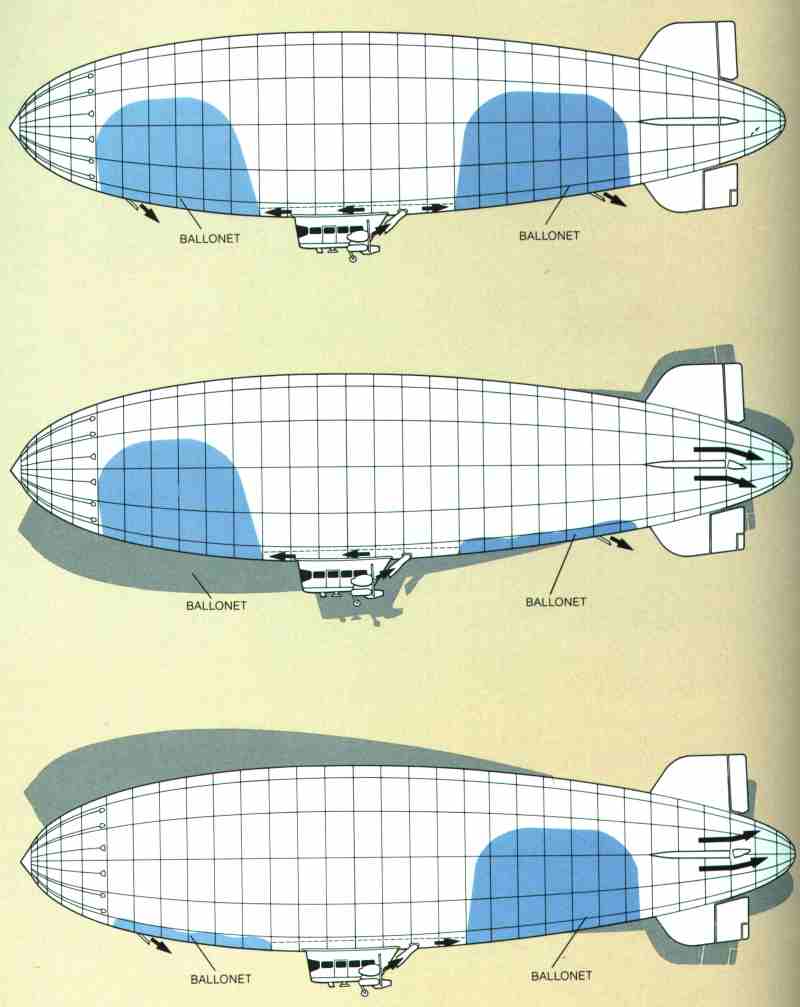

Role of the ballonets

The airship hull / envelope is divided into one or more sealed lifting gas volumes and separate gas volumes called “ballonets” that contain air at ambient, or near-ambient pressure. The ballonets serve as the expansion space that is available for the lifting gas cells as the airship ascends.

The ratio of the total envelope volume to the total ballonet volume is a measure of the expansion space for the lifting gas and is a key factor in determining the airship’s “pressure altitude.” This is the altitude at which the lifting gas cells are fully expanded, and the ballonets are empty. For example, with an envelope volume of 8,255 m3 (290,450 ft3) and a ballonet volume of 2,000 m3 (71,000 ft3), or about 24% of the envelope volume, a Zeppelin NT semi-rigid airship has a reported maximum altitude of 3,000 m (9,842 ft), with the envelope positive pressure of 5 mbar. With a smaller ballonet volume, the Zeppelin NT would have a lower maximum altitude at the specified internal pressure.

In semi-rigid and non-rigid airships with pressure-stabilized hulls, the ballonets are part of the airship’s pressure control system, which automatically maintains the envelope pressure in a desired range. Pressure control is accomplished by changing the volume of the ballonets. An air induction system draws atmospheric air and delivers it at a slight positive pressure (relative to envelope pressure) to increase ballonet volume. An air vent system will discharge air from the ballonets to the ambient atmosphere. While there is a change in mass during these ballonet operations, it is relatively small and does not significantly affect the aerostatic buoyancy of the airship.

Fore and aft ballonets can be operated individually to adjust the trim (pitch angle) of the airship. Inflating only the fore or aft ballonet, and allowing the opposite ballonet to deflate, will make the bow or stern of the airship slightly heavier and change the pitch angle of the airship without significantly affecting the overall aerostatic buoyancy. These ballonet operating principles are shown in the following diagrams of a blimp with two ballonets, which are shown in blue.

5.2 Variable buoyancy airships

Variable buoyancy airships can change their net lift, or “static heaviness,” to become lighter-than-air, neutrally buoyant or heavier-than-air as the circumstances require. Basic characteristics of variable buoyancy airships include the following:

- Variable buoyancy airships are capable of VTOL operations and hovering, usually with a full load.

- The buoyancy control system may enable in-flight load exchanges from a hovering airship without the need for external ballast.

- On the ground, variable buoyancy airships can make themselves heavier-than-air to facilitate load exchanges without the need for external infrastructure or ballast.

- It is not necessary for a “light” airship to vent the lifting gas to the atmosphere.

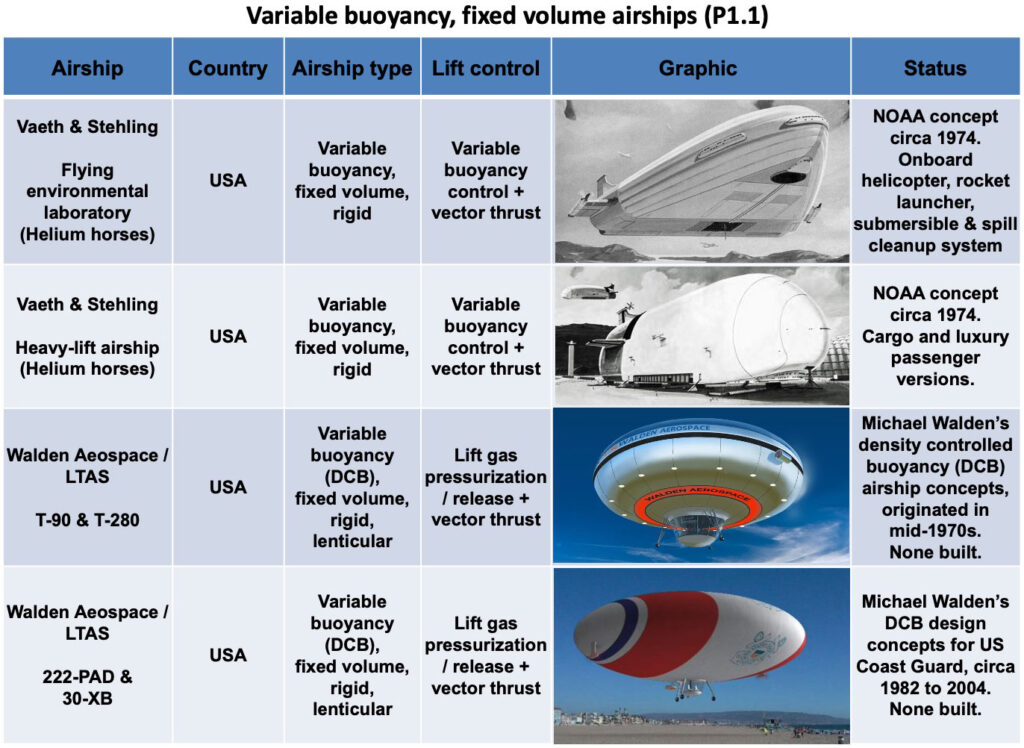

Variable buoyancy, fixed volume airships

Variable buoyancy commonly is implemented by adjusting the density of the lifting gas or a ballast gas, and thereby changing the static heaviness of a fixed volume airship. This also is referred to as density-controlled buoyancy (DCB). For example, a variable buoyancy / fixed volume airship can become heavier by compressing the helium lifting gas or ambient air ballast:

- Compressing some of the helium lifting gas into smaller volume tanks aboard the airship reduces the total mass of helium available to generate aerostatic lift.

- Compressing ambient air into pressurized tanks aboard the airship adds mass (ballast) to the airship and thus decreases the net lift.

The airship becomes lighter by venting the pressurized gas tanks:

- Compressed helium lifting gas is vented back into the helium lifting gas cells, increasing the mass of helium available to generate aerostatic lift.

- Compressed air is vented to the atmosphere, reducing the mass of the airship and thus increasing net lift.

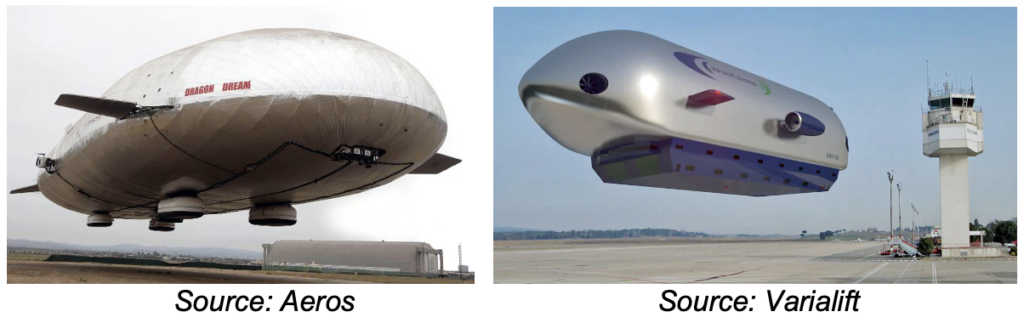

The Aeros Aeroscraft Dragon Dream and the Varilift ARH-50 are examples of variable buoyancy / fixed volume airships.

Variable buoyancy, fixed volume, variable vacuum airships

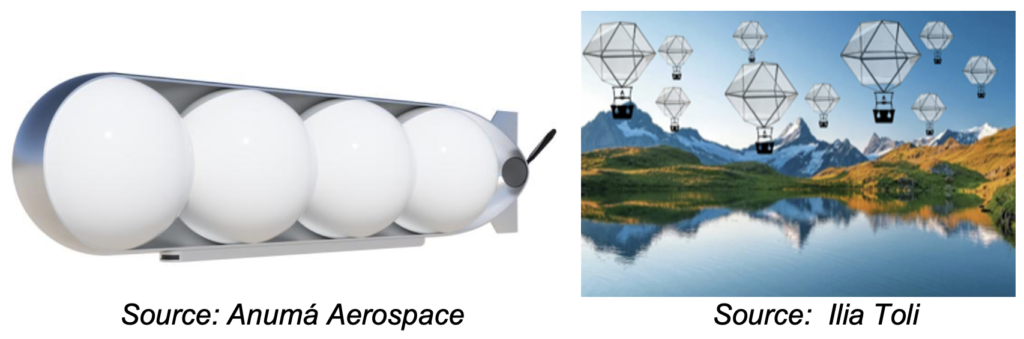

Instead of using a low-density gas to generate aerostatic lift, a vacuum airship uses very low-density air (a partial vacuum) to generate lift, which can be controlled by managing the vacuum conditions inside lightweight, fixed volume structures capable of retaining the vacuum. The key challenge is making the variable vacuum containment and associated systems light enough to generate net lift. Once that has been achieved, then the challenge will be to package that variable buoyancy / variable vacuum system into a functional airship. These challenges have been accepted by Anumá Aerospace and by engineer Ilia Toli.

Variable buoyancy, variable volume airships

Variable buoyancy also can be implemented by adjusting the total volume of the helium envelope without changing the mass of helium in the envelope.

- As the size of the helium envelope increases, the airship displaces more air and the buoyant force of the atmosphere acting on the airship increases. Static heaviness decreases.

- As the size of the helium envelope decreases, the airship displaces less air and the buoyant force of the atmosphere acting on the airship decreases. Static heaviness increases.

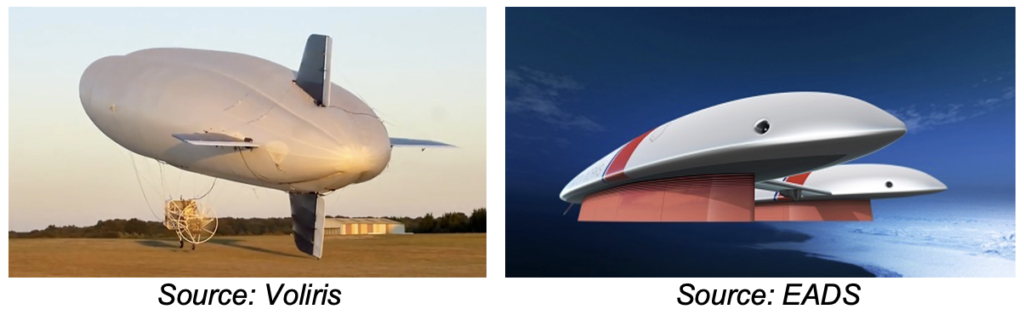

The concept for a variable buoyancy / variable volume airship seems to have originated in the mid-1970s with inventor Arthur Clyde Davenport and the firm Dynapods, Inc. The tri-lobe Voliris airships and the EADS Tropospheric Airship are modern examples of variable buoyancy / variable volume airships.

Variable buoyancy, hybrid thermal-gas (Rozière) airships

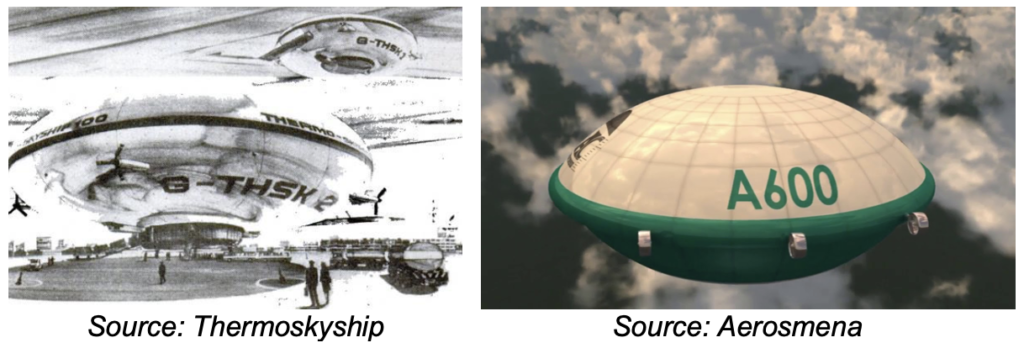

This buoyancy control concept was developed and applied in the 1700s in hybrid balloons designed by Jean-François Pilâtre de Rozière. Such “Rozière” balloons have separate chambers for a non-heated lift gas (hydrogen or helium) and a heated lift gas (air). This concept has been carried over into airships. With helium alone the airship is semi-buoyant (heavier-than-air). Buoyancy is managed by controlling the heating and cooling of the air in a separate “thermal volume.” Examples of hybrid thermal (Rozière) airships are the British Thermo-Skyship (circa 1970s to early 1980s), Russian Thermoplane ALA-40 (circa 1980s to early 1990s), and the heavy-lift Aerosmena (AIDBA) “aeroplatform” currently being developed in Russia. All are lenticular (lens-shaped) airships.

Variable buoyancy propulsion airships / aircraft

Back in the 1860s, Dr. Solomon Andrews invented the directionally maneuverable, hydrogen-filled airship named Aereon that used variable buoyancy (VB) and airflow around the airship’s gas envelope to provide propulsion without an engine.

VB propulsion airships / aircraft fly a repeating sinusoidal flight profile in which they gain altitude as positively buoyant hybrid airships, then decrease their buoyancy at some maximum altitude and continue to fly under the influence of gravity as a semi-buoyant glider. After gradually losing altitude during a long glide, the pilot increases buoyancy and starts the climb back to higher altitude in the next cycle.

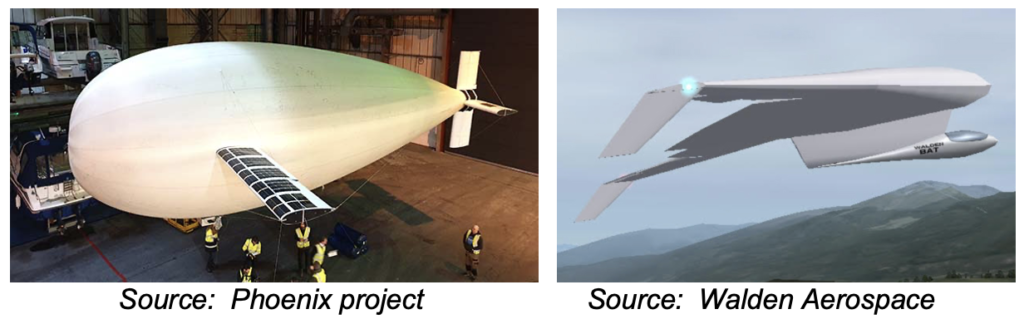

The UK’s Phoenix and Michael Walden’s HY-SOAR BAT concept are two examples of variable buoyancy propulsion airships / aircraft.

5.3 Semi-buoyant, hybrid air vehicles

Semi-buoyant, hybrid airships

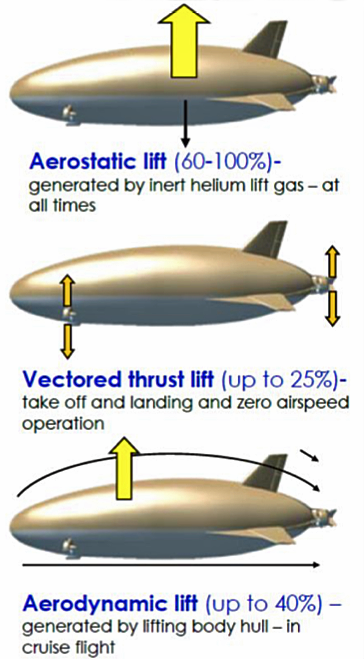

Hybrid airships are heavier-than-air (HTA) vehicles. The term “semi-buoyant” means that the lifting gas provides only a fraction of the needed lift (typically 60 – 80%) and the balance of the lift needed for flight is generated by other means, such as vectored thrust engines and aerodynamic lift from the fuselage and wings during forward flight.

Sources of lift for a semi-rigid, hybrid airship.

Source: DoD 2012

Basic characteristics of hybrid airships include the following:

- This type of airship requires some airspeed to generate aerodynamic lift. Therefore, it typically makes a short takeoff and landing (STOL).

- Some hybrid airships may be capable of limited VTOL operations (i.e., when lightly loaded, or when equipped with powerful vectored thrust engines).

- Like conventional airships, the gas envelope in hybrid airship is divided into one or more lifting gas volumes and separate ballonet volumes containing ambient air.

- Hybrid airships are heavier-than-air and are easier to control on the ground than conventional airships.

There are three types of hybrid airships: non-rigid, semi-rigid and rigid.

- Non-rigid hybrid airships: This type of hybrid airship has a pressure-stabilized, flexible, multi-layer fabric gas envelope that would collapse if the internal pressure were lost. Catenary curtains inside the gas envelope support a gondola and distribute loads into the upper surfaces of the envelope. Ballonets control the pressure inside the gas envelope and can be used to control pitch angle, as on conventional blimps. The wide hybrid airships may have separate ballonets on each side of the inflated envelope that can be used to adjust the roll angle.

- Semi-rigid hybrid airships: This type of hybrid airship has a substantial load-carrying, rigid structure, which may be a large keel or a more complex rigid framework inside the gas envelope, that is connected via a load distribution system to the flexible, pressurized envelope that defines the exterior shape and contains air ballonets.

- Rigid hybrid airships: This type of hybrid airship has a substantial rigid structure that defines the shape of the exterior aeroshell. The “hard” skin of the airship may be better suited for operation in Arctic conditions, where snow loads and high winds might challenge the integrity of a pressure-stabilized gas envelope on a non-rigid or semi-rigid airship.

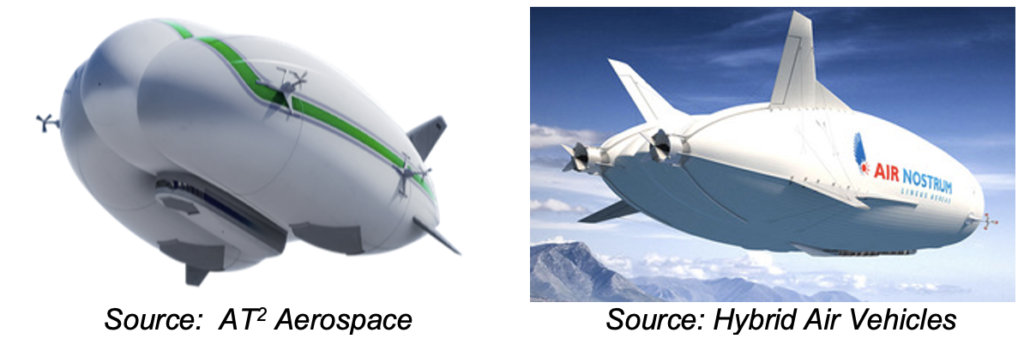

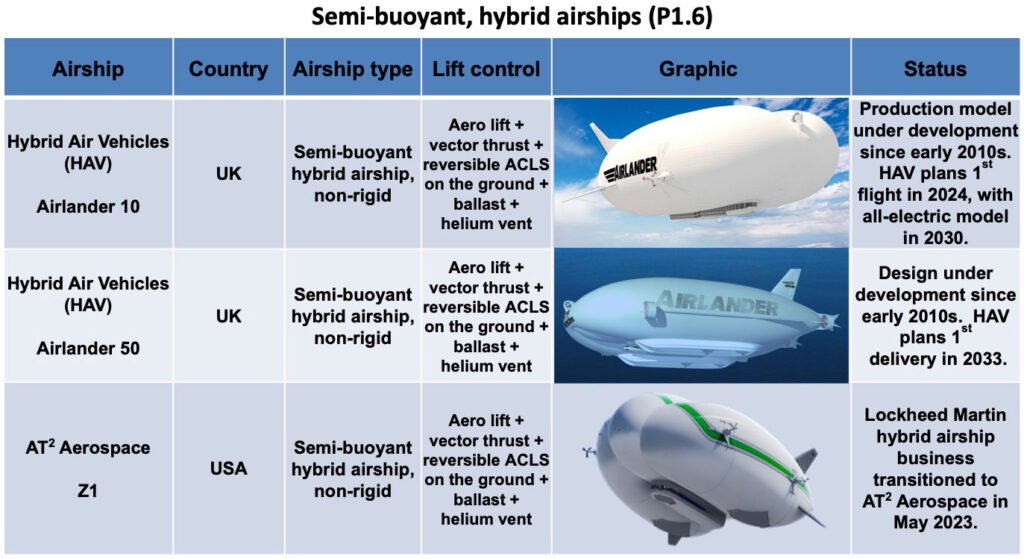

The AT2 Aerospace Z1 and the HAV Airlander 10 are examples of large hybrid airships that are under development in 2023. Their propulsion engines are attached directly to reinforced areas of the fabric gas envelope and are supported by localized load distribution systems (i.e., distributed cable stays). Their gas envelopes have no rigid internal structures, and in that respect they resemble blimps.

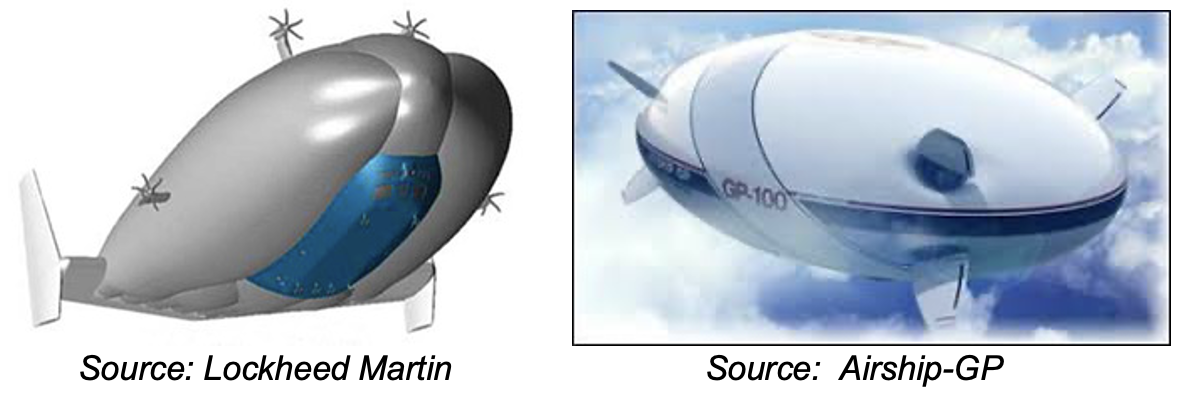

The Lockheed Martin Aerocraft is an example of a semi-rigid hybrid airship with a substantial, load-carrying, internal rigid structure that enabled the designers to support large propulsion engines in locations that may not otherwise be practical. The AeroTruck being developed by Russian firm Airship-GP is an example of a rigid hybrid airship. The rigid structure is designed for operating in extreme Arctic conditions and parking outdoors where snow loads and icing may be routine problems. Airship-GP also is developing a more complex variable buoyancy model of the AeroTruck.

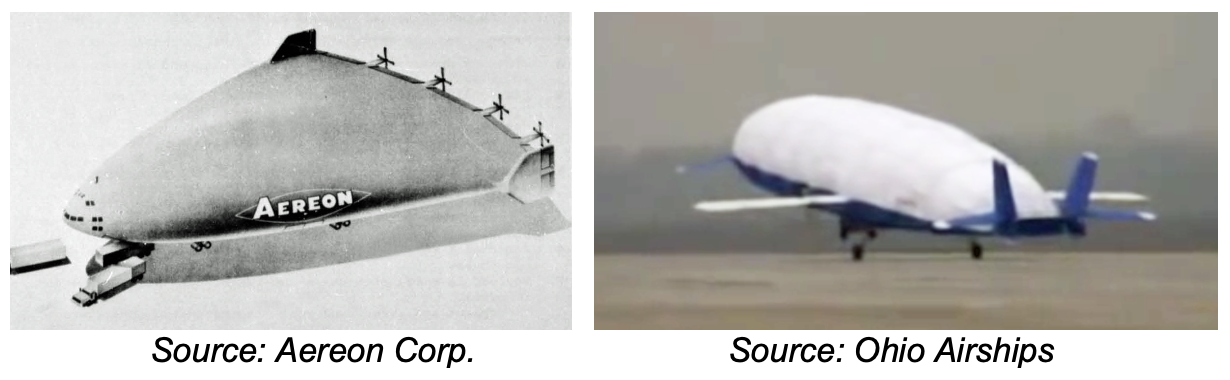

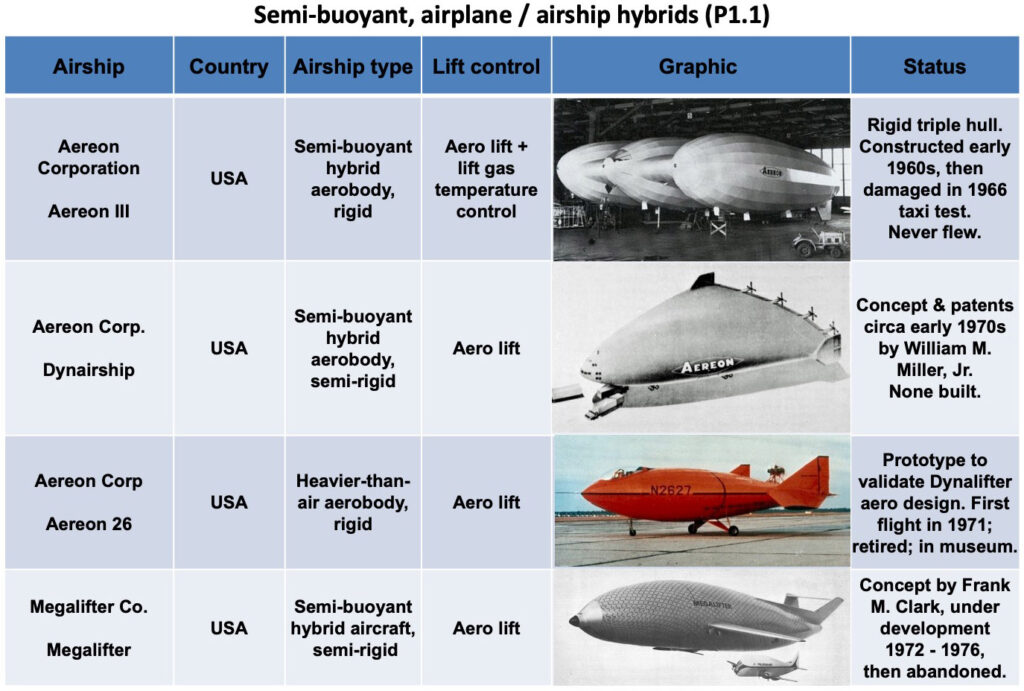

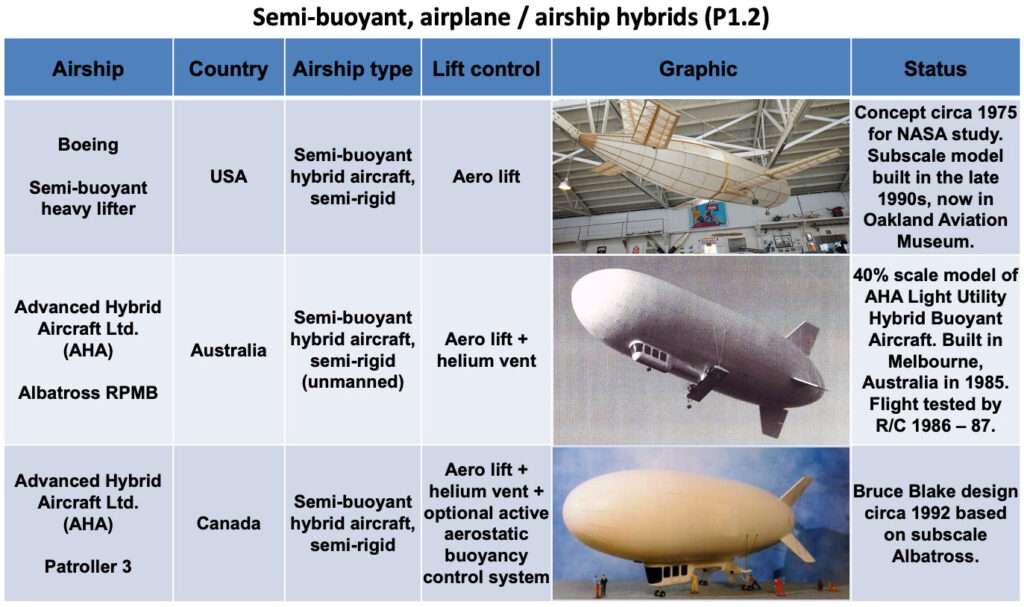

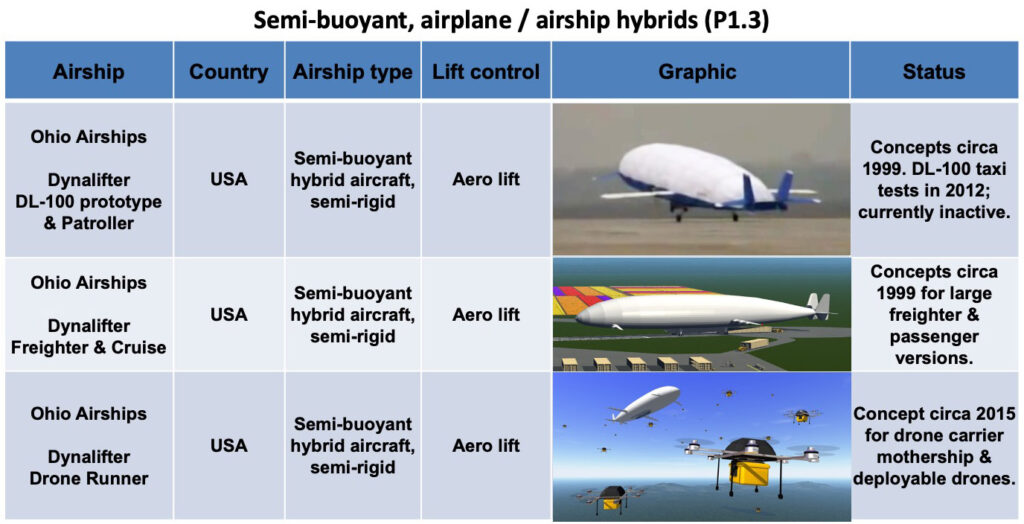

Semi-buoyant, airplane / airship hybrids

Semi-buoyant airplane / airship hybrids are heavier-than-air, rigid, winged aircraft that carry a large helium volume to significantly reduce the weight of the aircraft and improve its load-carrying capability. Aerostatic lift provides a smaller fraction of total lift for a semi-buoyant aircraft, like a Dynalifter, than it does for a semi-buoyant, hybrid airship.

A semi-buoyant airplane / airship hybrids behaves much like a conventional aircraft in the air and on the ground, and is less affected by wind gusts and changing wind direction on the ground than a hybrid airship.

The semi-buoyant airplane / airship hybrids has some flexibility for loading and discharging cargo without having to be immediately concerned about exchanging ballast, except in windy conditions.

The Aereon Corporation’s Dynairship and the Ohio Airships Dynalifter are examples of semi-buoyant airplane / airship hybrids.

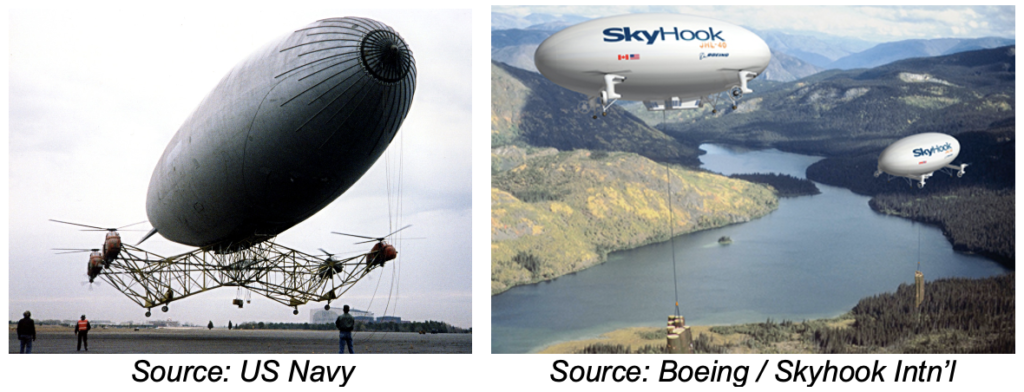

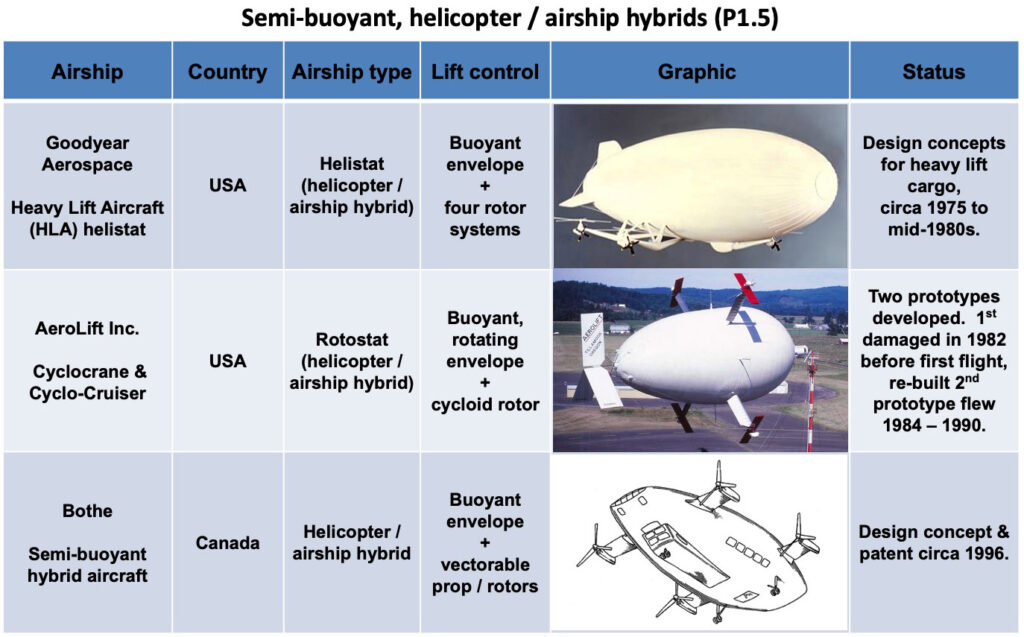

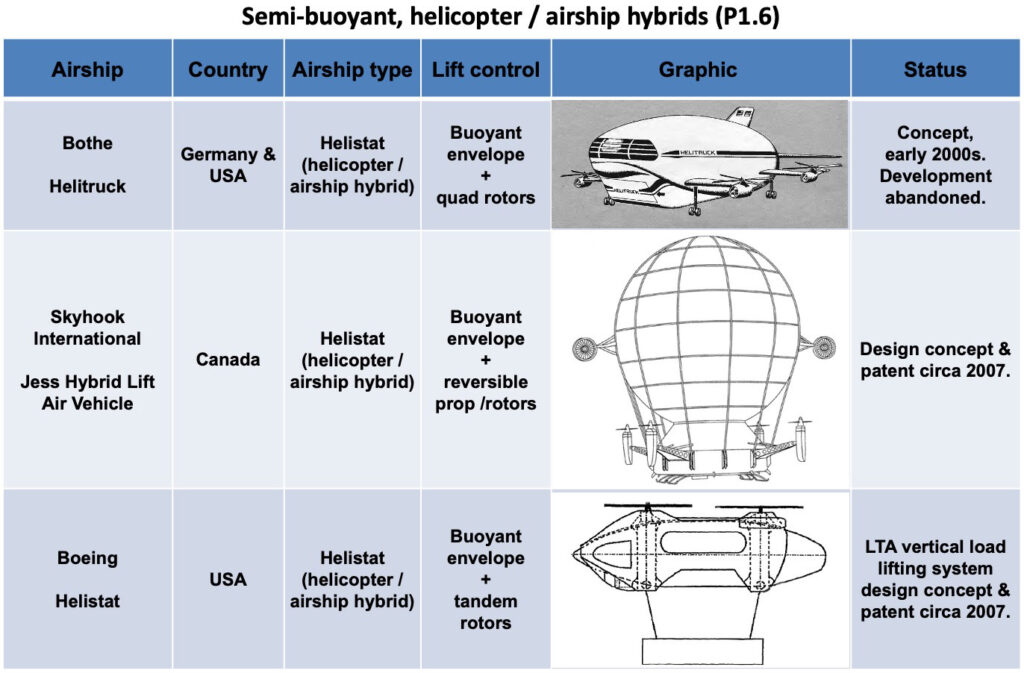

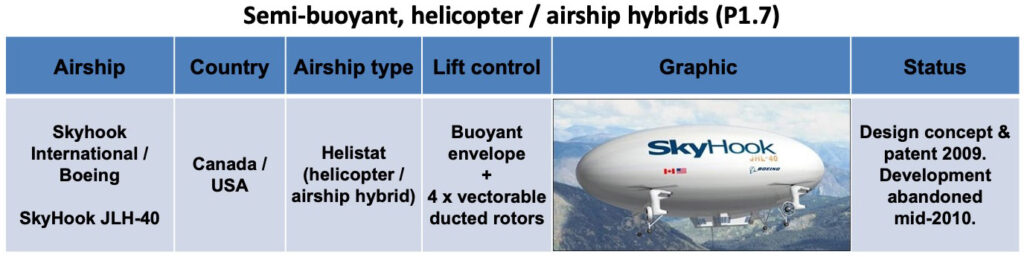

Semi-buoyant, helicopter / airship hybrids

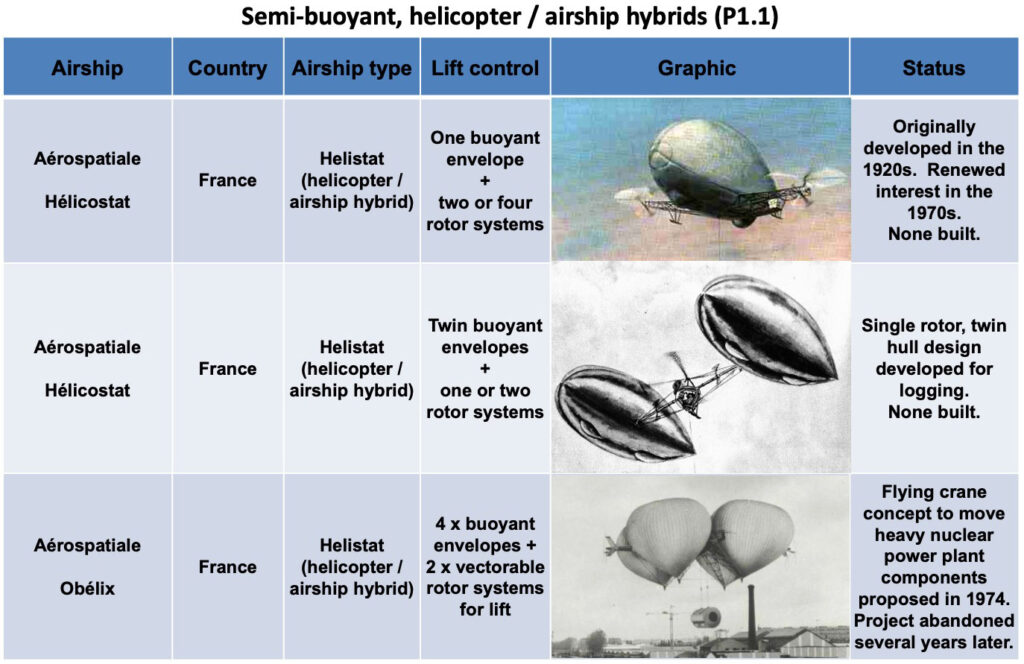

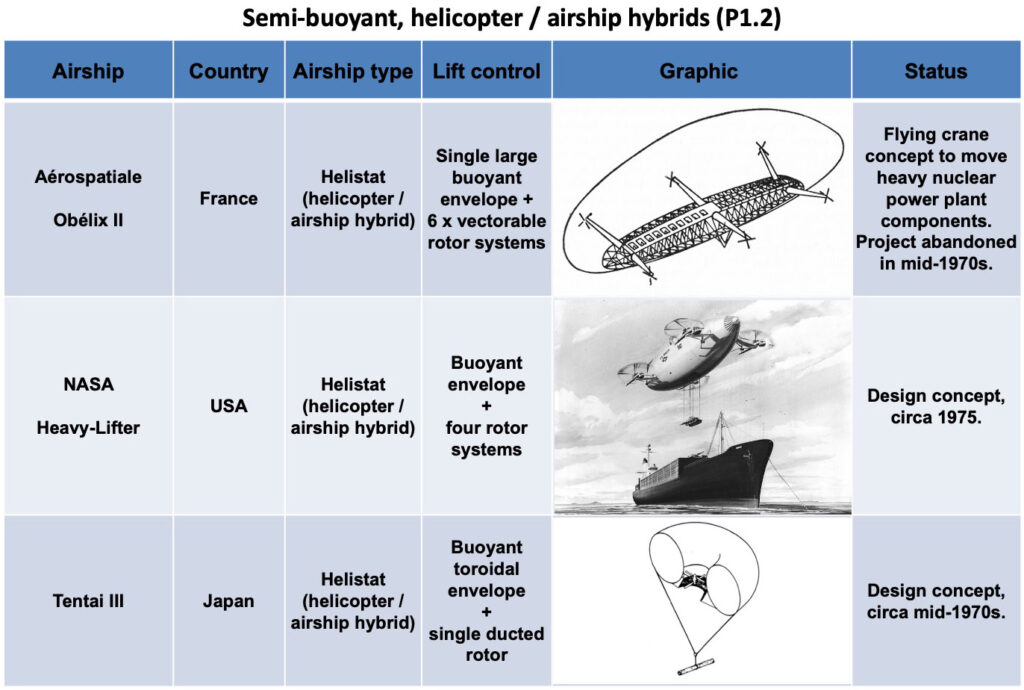

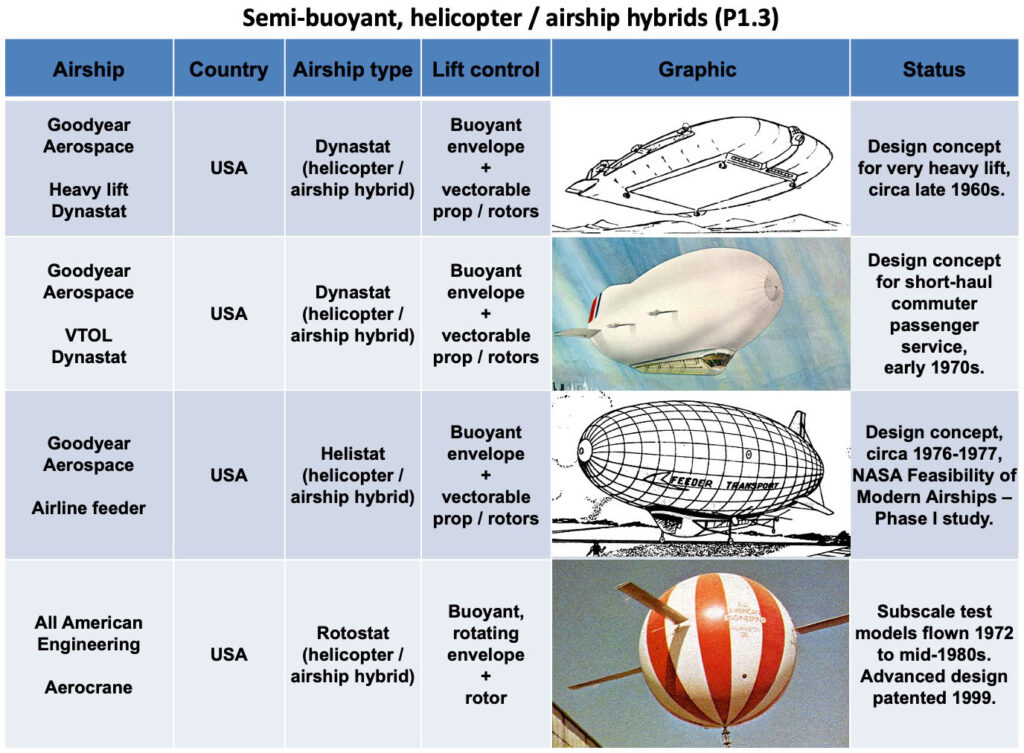

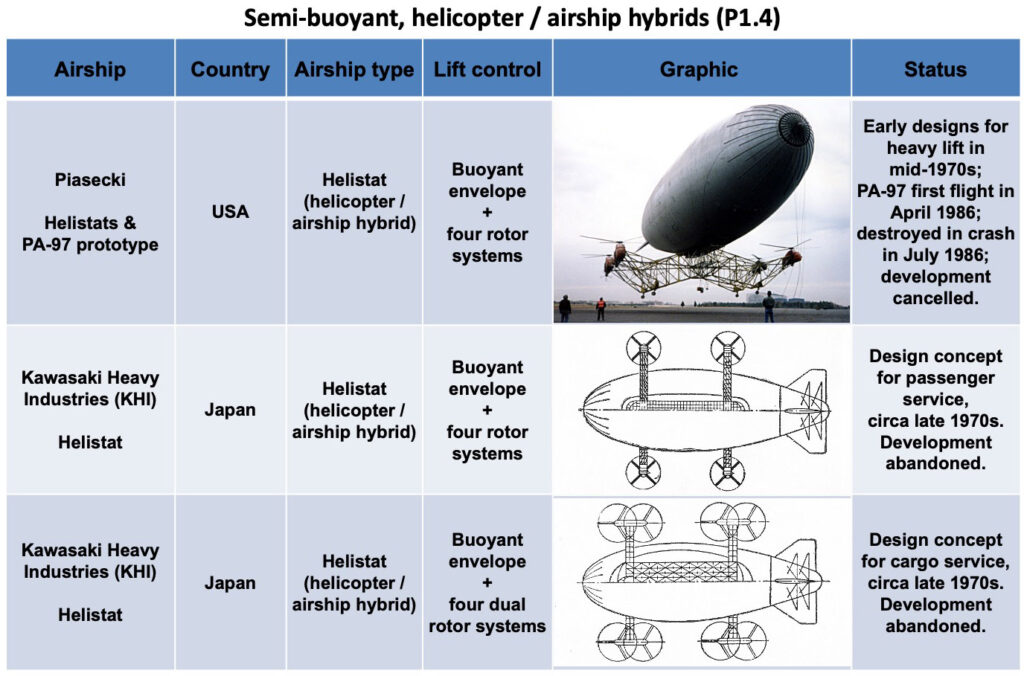

There have been many different designs of helicopter / airship hybrids, including helistats, Dynastats and rotostats. Typically, the airship part of the hybrid craft carries the weight of the craft itself and helicopter rotors deployed in some manner around the airship work in concert to propel the craft and lift and deliver heavy payloads without the need for an exchange of ballast.

The Piasecki PA-97-34J and the Boeing / Skyhook International SkyHook JLH-40 are examples of helistats.

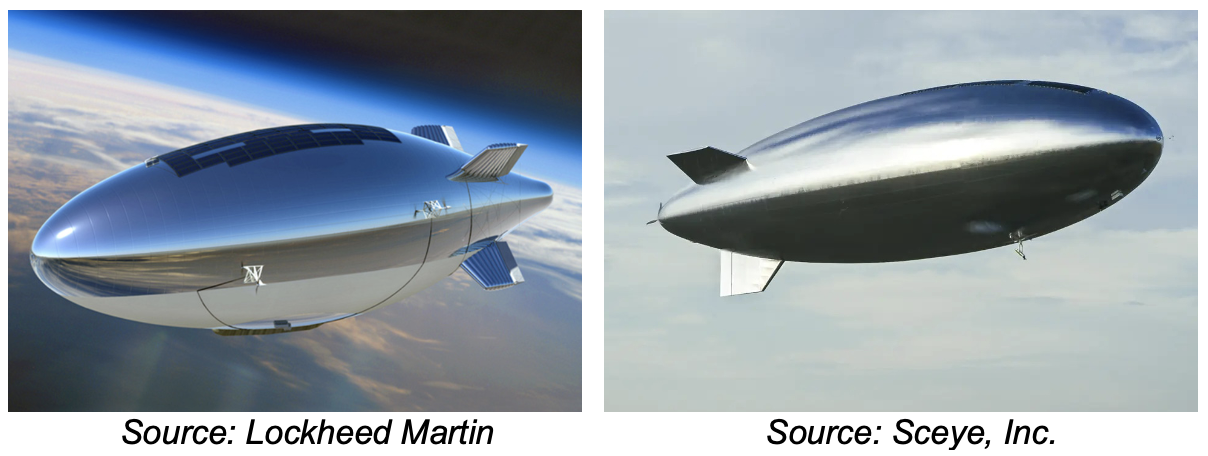

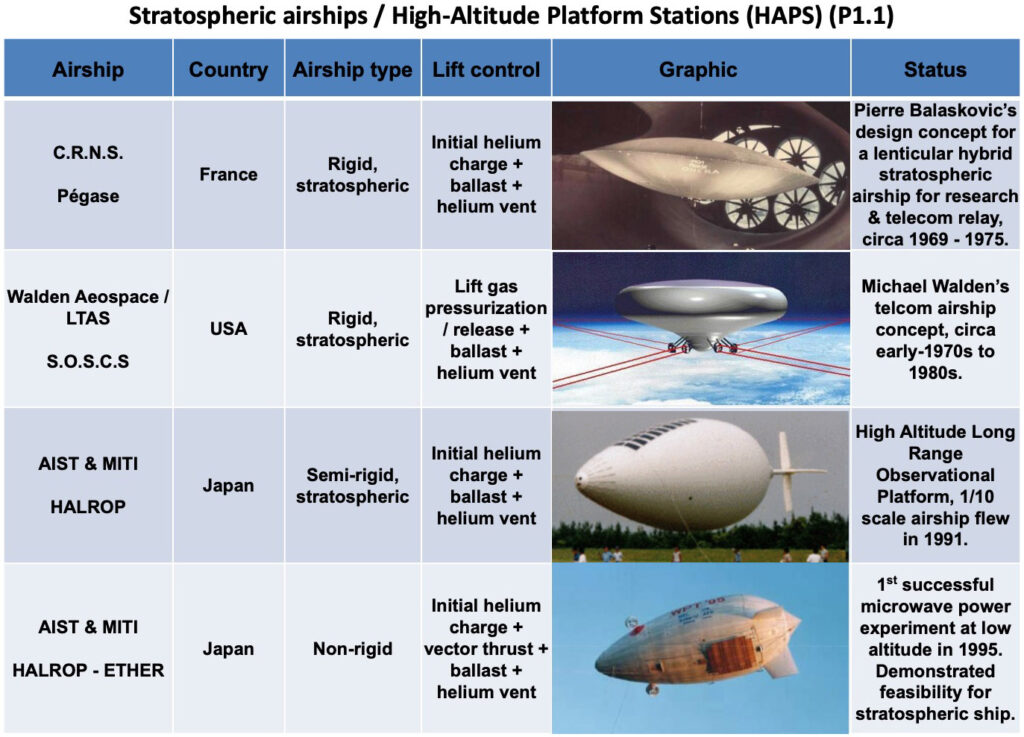

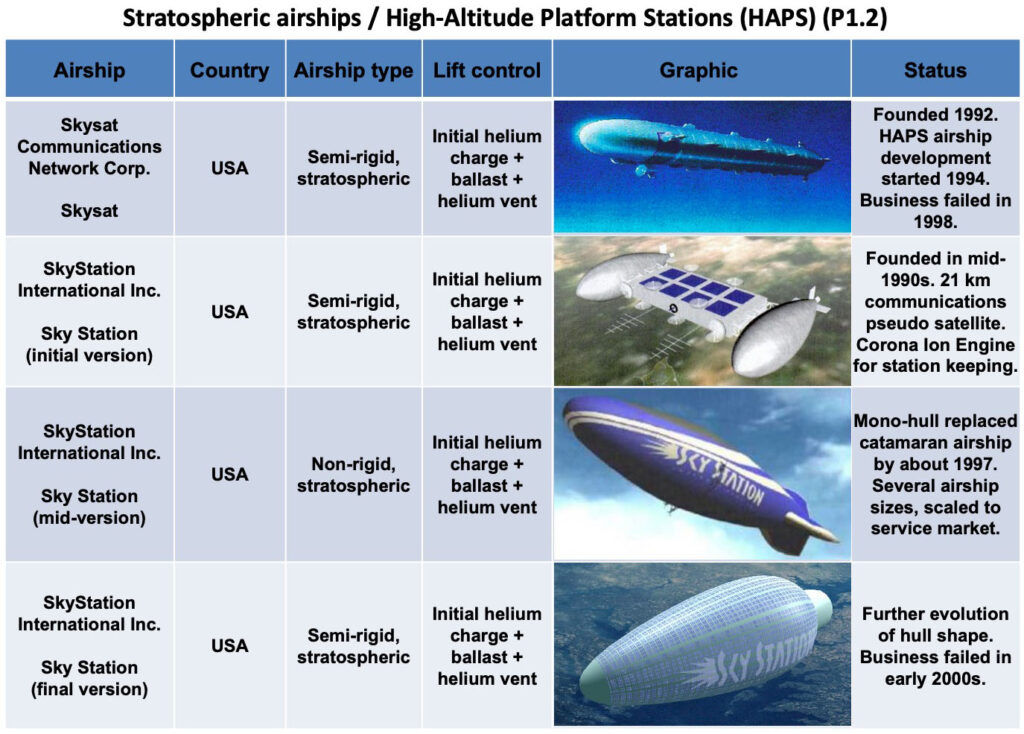

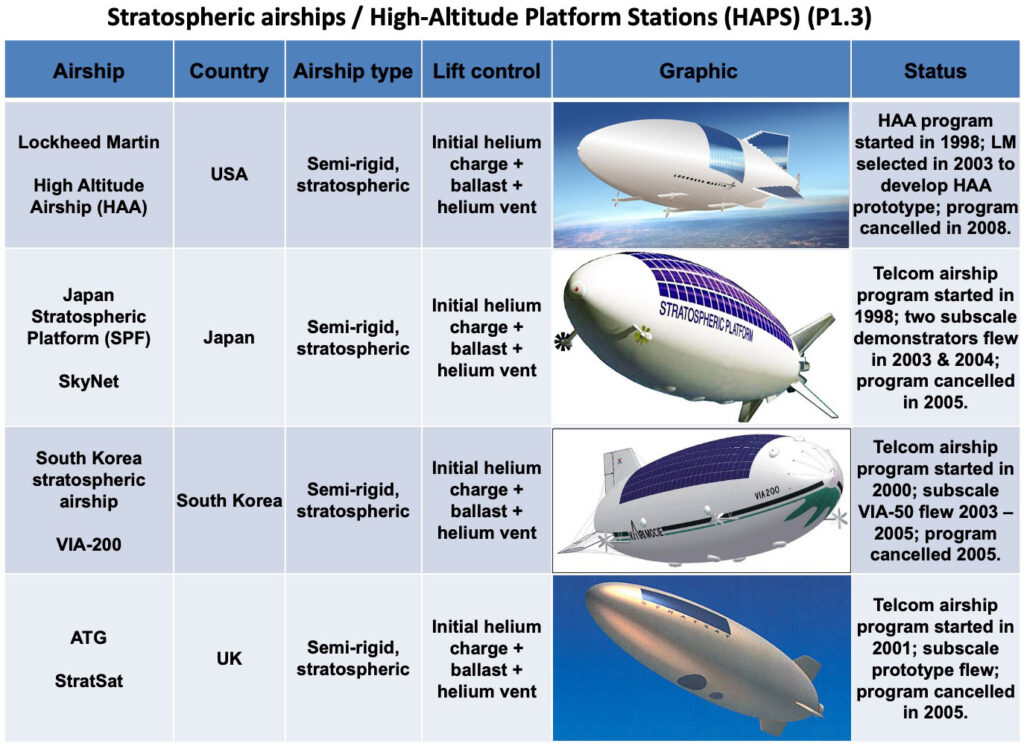

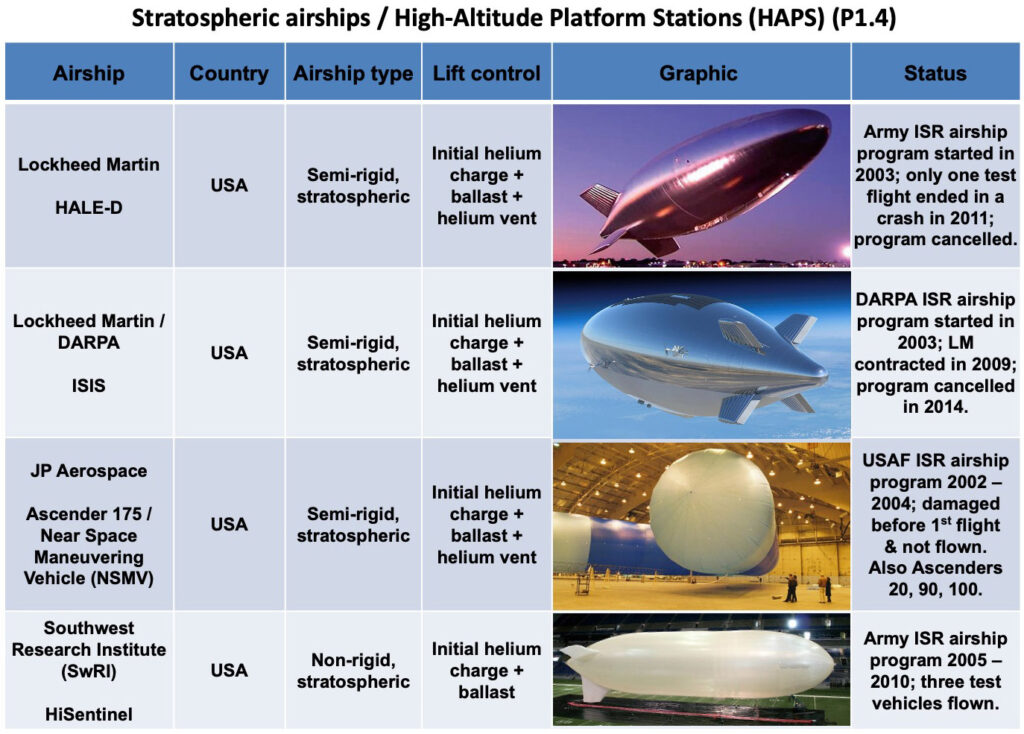

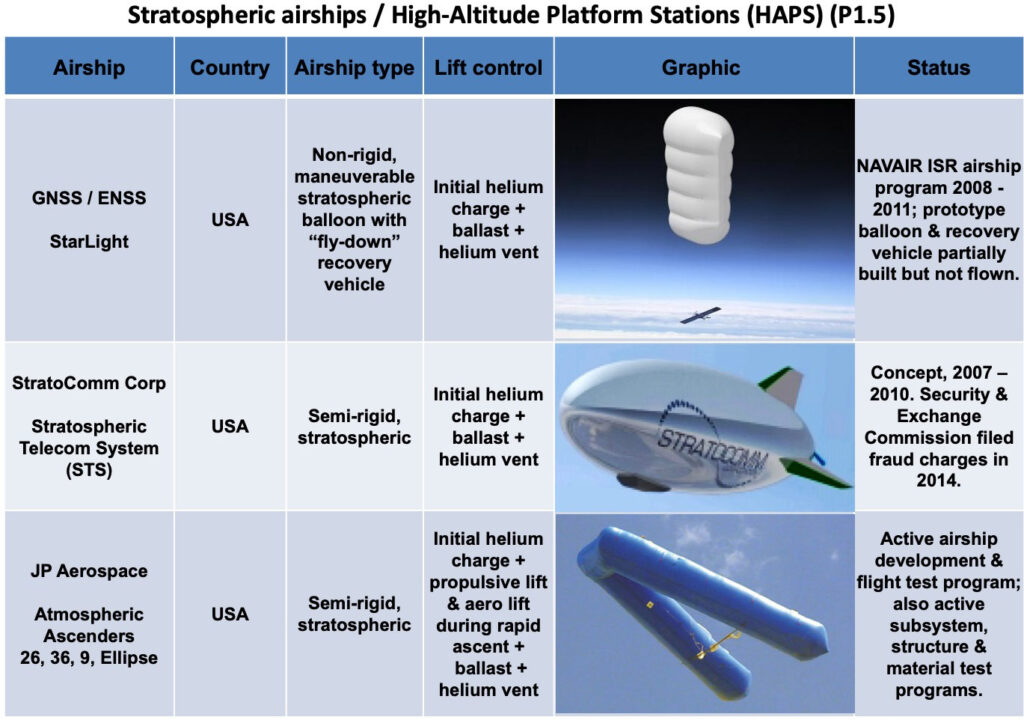

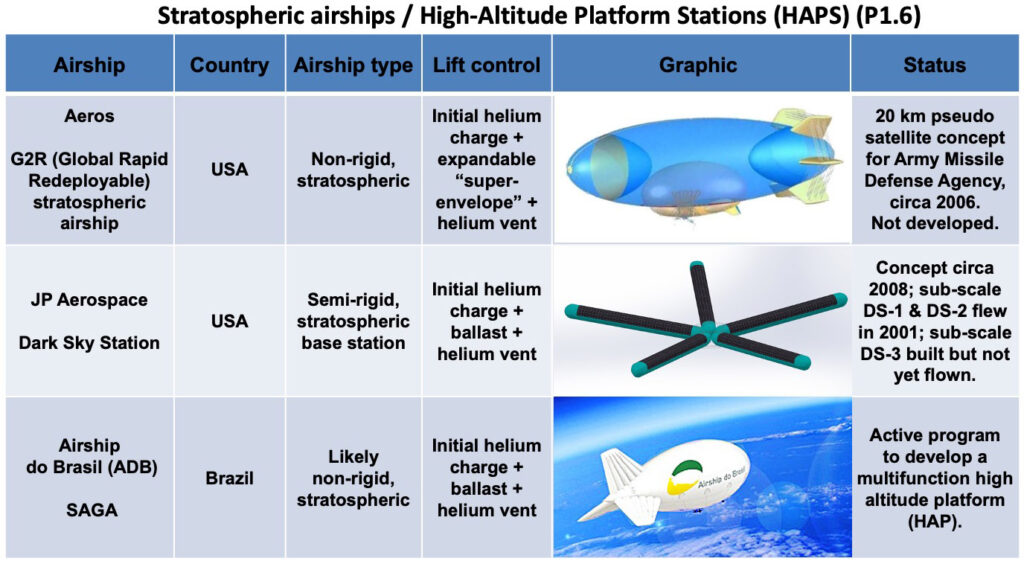

5.4 Stratospheric airships / High Altitude Platform Stations (HAPS)

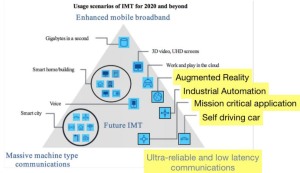

Stratospheric airships are designed to operate at very high-altitudes, well above the jet stream and in a region of relatively low prevailing winds typically found at altitudes of 60,000 to 75,000 feet (11.4 to 14.2 miles / 18.3 to 22.9 km). This is a harsh environment where airship materials are exposed to the damaging effects of ultraviolet radiation and corrosive ozone. These airships are designed as unmanned vehicles.

Applications for stratospheric airships include military intelligence, surveillance and reconnaissance (ISR) missions, civil environmental monitoring / resource management missions, military / civil telecommunications / data relay functions, and research missions such as high-altitude astronomy. All of these can be long term missions that can last weeks, months or even years.

Typically, the stratospheric airship will operate as a “pseudo-satellite” from an assigned geo-stationary position. Station keeping 24/7 is a unique challenge. Using a hybrid electric power system, these airships can be solar-powered during the day and then operate from an energy storage source (i.e., a battery or regenerative fuel cell) at night. Some propulsion systems, such as propellers that work well at lower altitudes, may have difficulty providing the needed propulsion for station keeping or transit in the very low atmospheric pressure at operating altitude.

The DARPA / Lockheed Martin ISIS airship and the Sceye Inc. high-altitude platform are two examples of stratospheric airships.

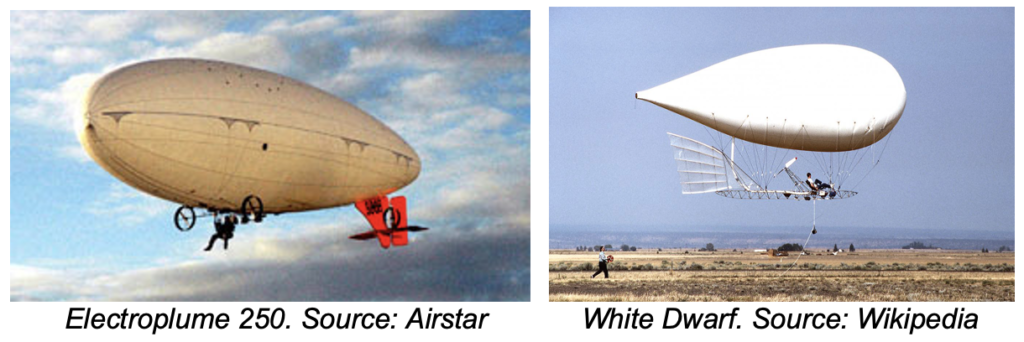

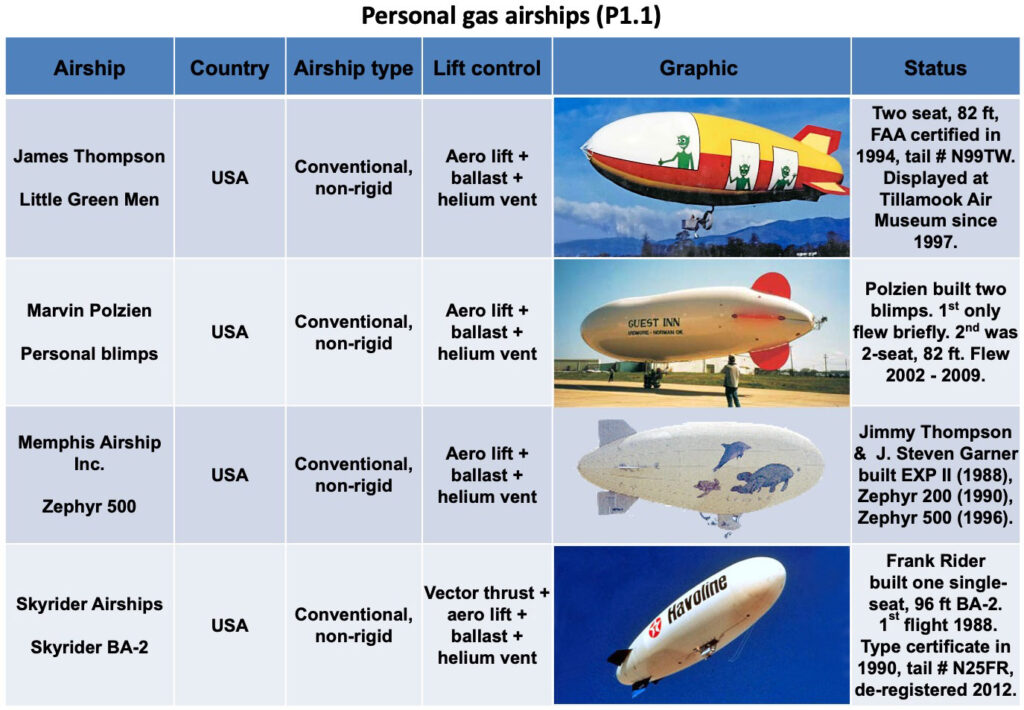

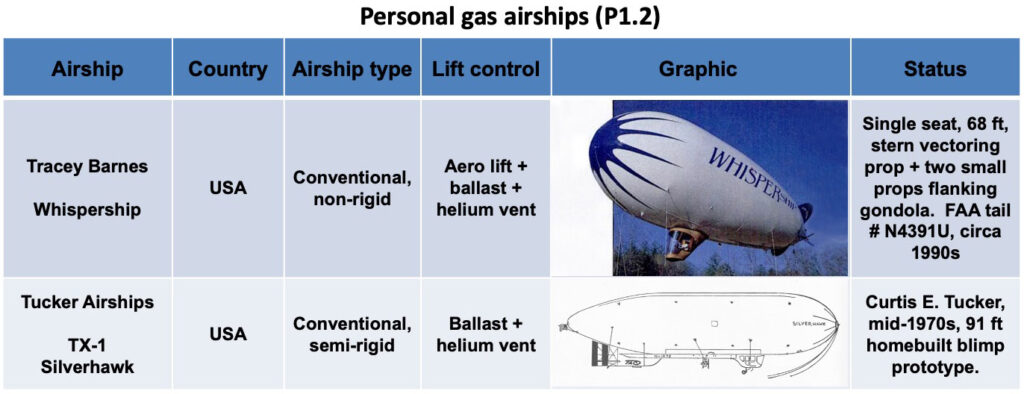

5.5 Personal gas airships

Personal airships include a range of small LTA craft, from ultra-light, single seat recreational airships (ULM Class 5) to larger airships with a passenger capacity comparable to a personal automobile. Personal airships typically are conventional non-rigid or semi-rigid airships. They may be powered by various means, including petrol engine, electric motor, or even human-powered.

The French firm Airstar has built and flown several ultra-light airships, such as the all-electric Electroplume 250. Bryan Allen’s White Dwarf is an example of a pedal-powered personal airship.

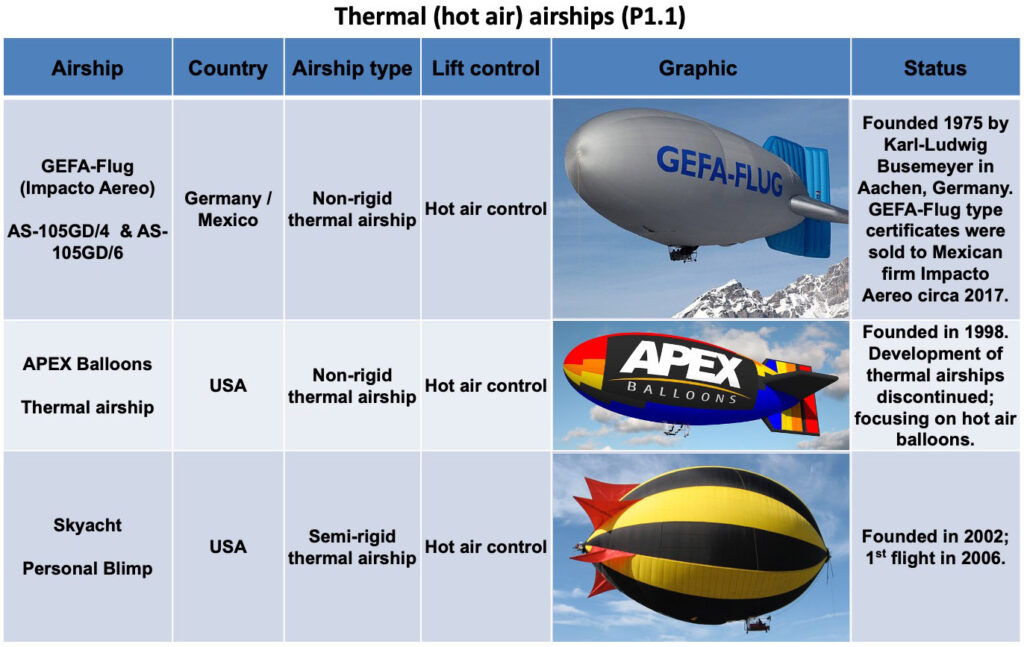

5.6 Thermal (hot air) airships

Thermal airships use hot air as the lifting gas in place of helium or hydrogen. A given volume of hot air can lift only about one-third as much as the same volume of helium. Therefore, the gas envelope on a thermal airship is proportionally larger than it would be on a comparable airship using helium as the lifting gas.

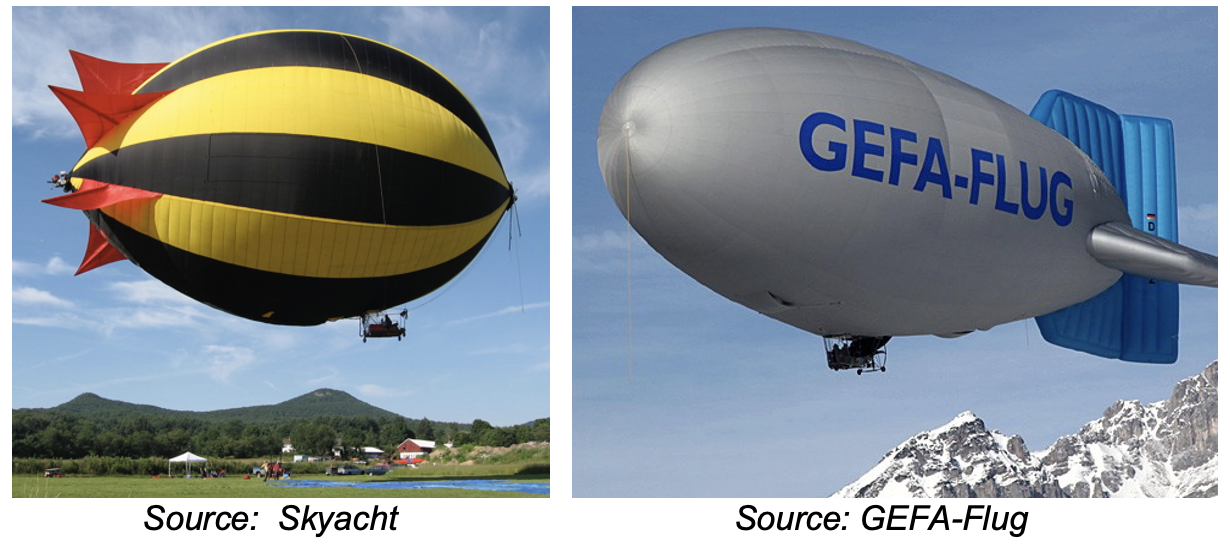

The non-rigid GEFA-Flug four-seat AS-105GD/4 and six-seat AS-105GD/6, and the semi-rigid, two-seat Skyacht Personal Blimp are examples of current thermal airships that use propane burners to produce the hot air for lift. Pitch can be controlled with fore and aft burners. There are no ballonets.

Advanced concepts for solar-powered thermal airships are described in Modern Airships – Part 3.

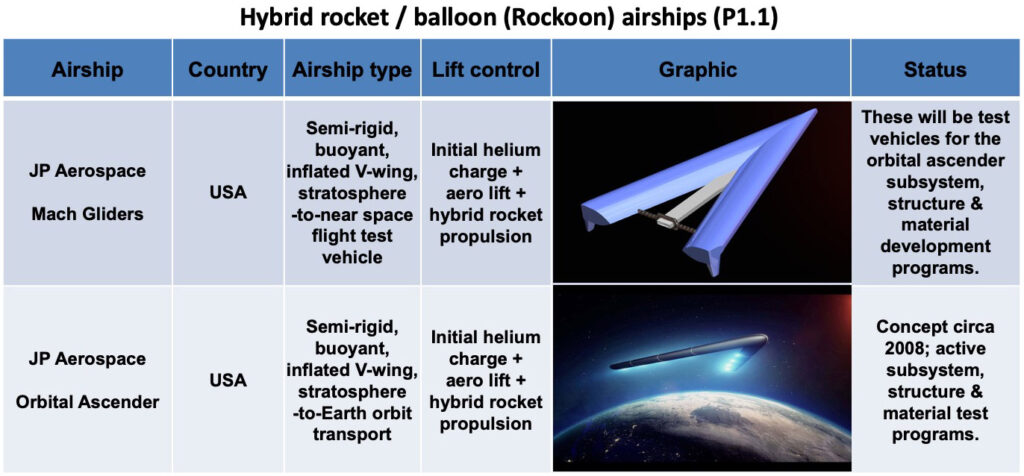

5.7 Hybrid rocket / balloon (Rockoon) airships

The term “Rockoon” has been used to refer to a ground-launched, high-altitude balloon that carries a small sounding rocket aloft to be launched in the stratosphere, perhaps 15 to 20 miles (24 to 32 km) above the ground. Starting the rocket’s powered flight at high-altitude enables it to reach a much higher altitude than from a conventional ground launch.

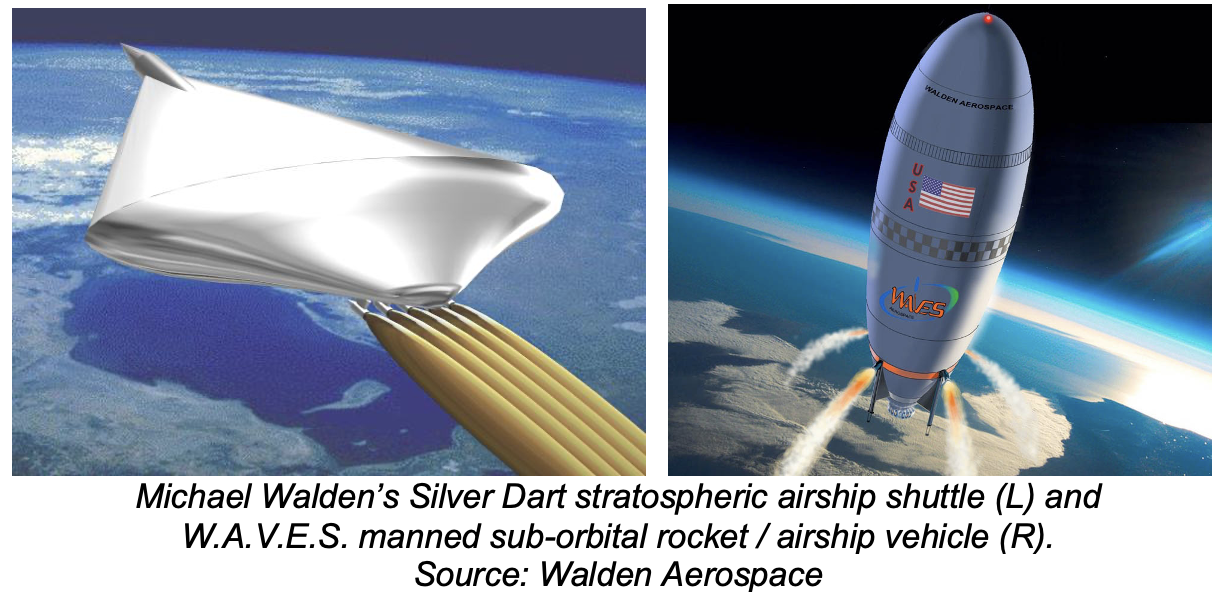

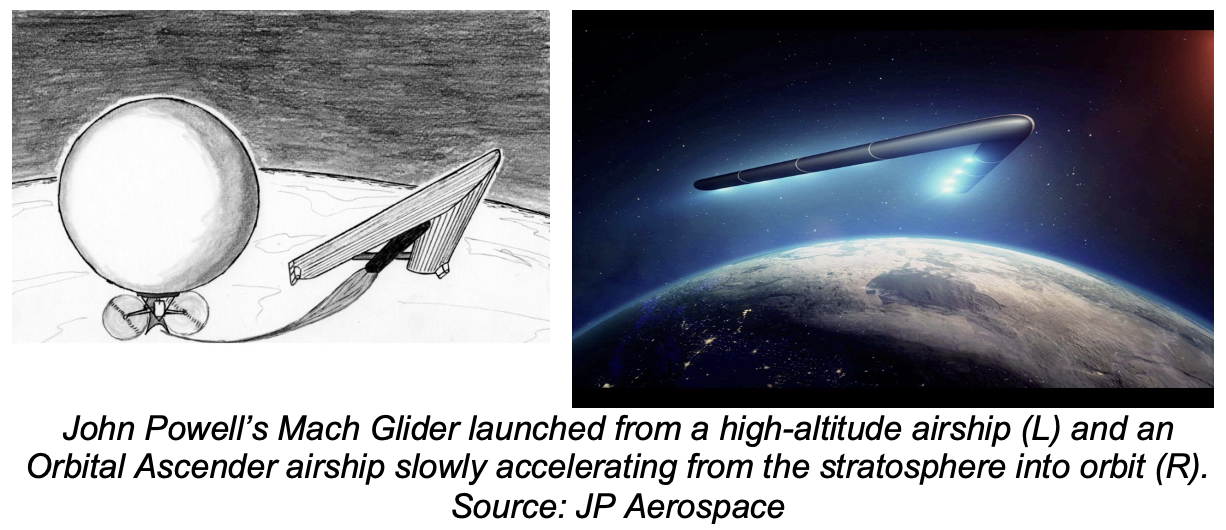

Airship designers Michael Walden (LTAS / Walden Aerospace) and John Powell (JP Aerospace) have applied the rocket / balloon hybrid concept more broadly to produce several diverse design concepts for airships capable of operating in the stratosphere, in near-space, and all the way to Earth orbit.

For more than a decade, JP Aerospace has been developing electric / chemical MHD (magnetohydrodynamic) hybrid plasma engines for use in their planned Trans-atmospheric and Orbital Ascender airships.

5.8 Electro-kinetically (EK) propelled airships

EK propulsion uses electrostatic and/or electromagnetic fields to generate thrust, typically a rather low thrust with currently available hardware. In principle, EK propulsion could be used in place of conventional propulsion means, such as propellers and turbine engines, particularly on airships that operate in the stratosphere.

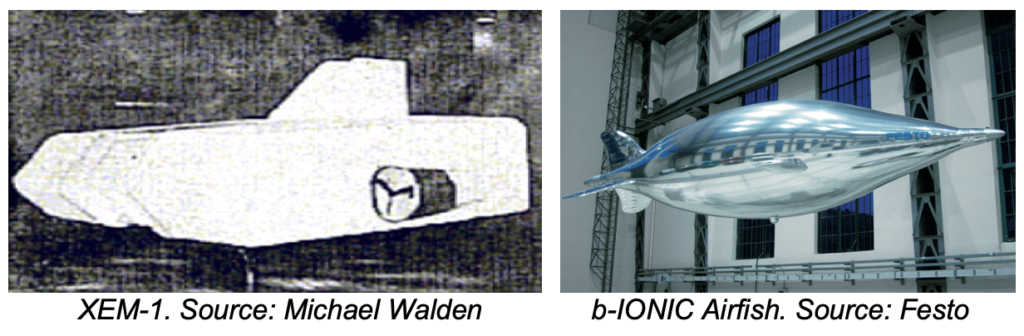

EK propulsion has been demonstrated experimentally with small, neutrally-buoyant airships, such as Michael Walden’s (LTAS / Walden Aerospace) XEM-1 rigid, hybrid EK drive demonstrator that first flew in 1974, and the graceful, non-rigid b-IONIC Airfish that was developed and flown in 2005 by the German firm Festo.

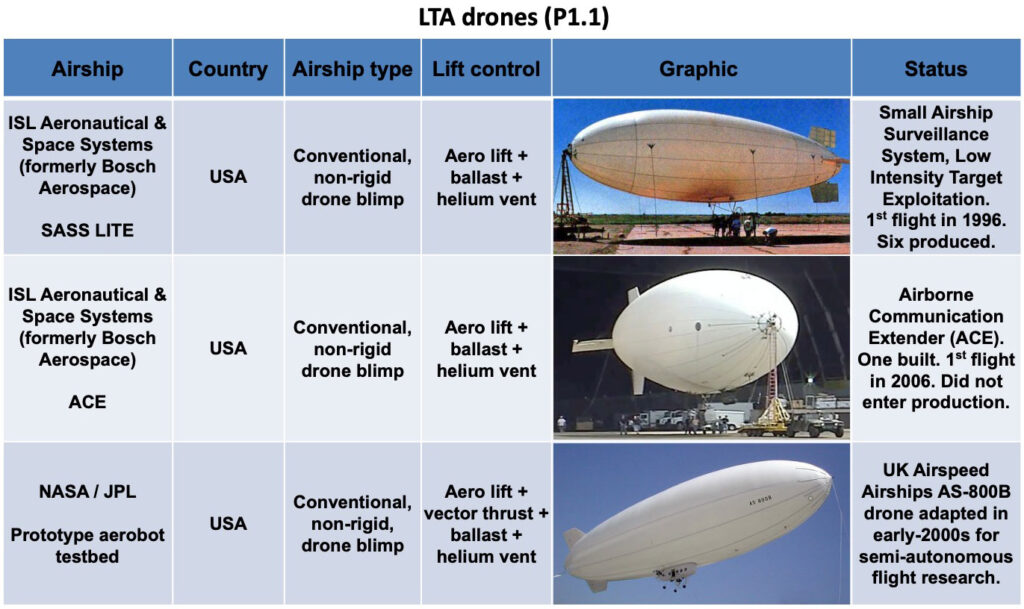

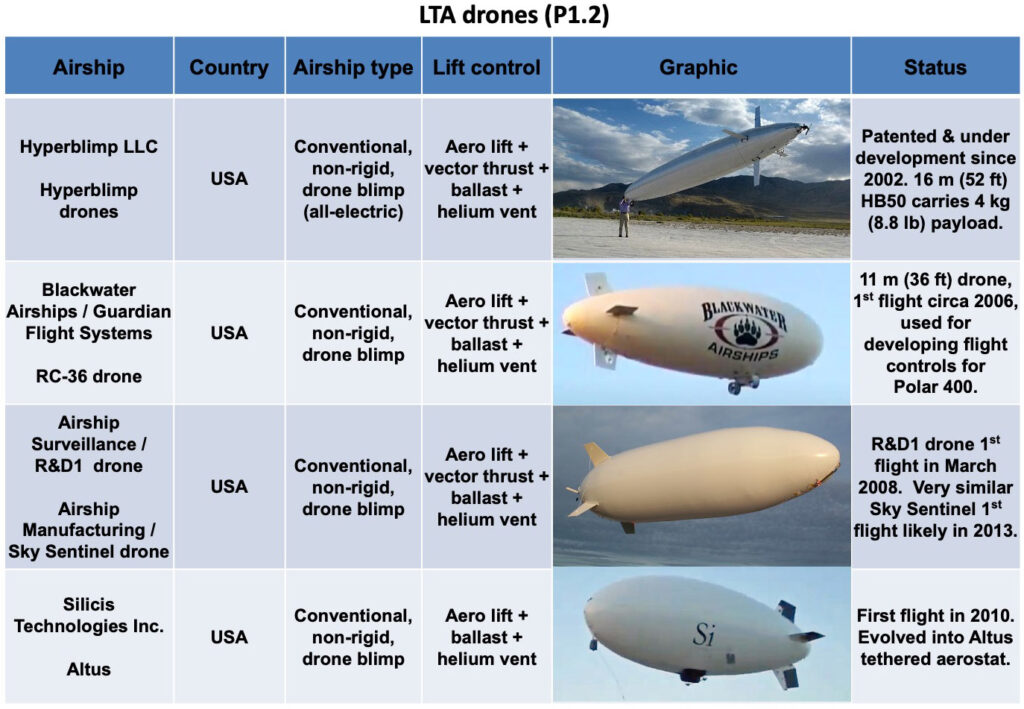

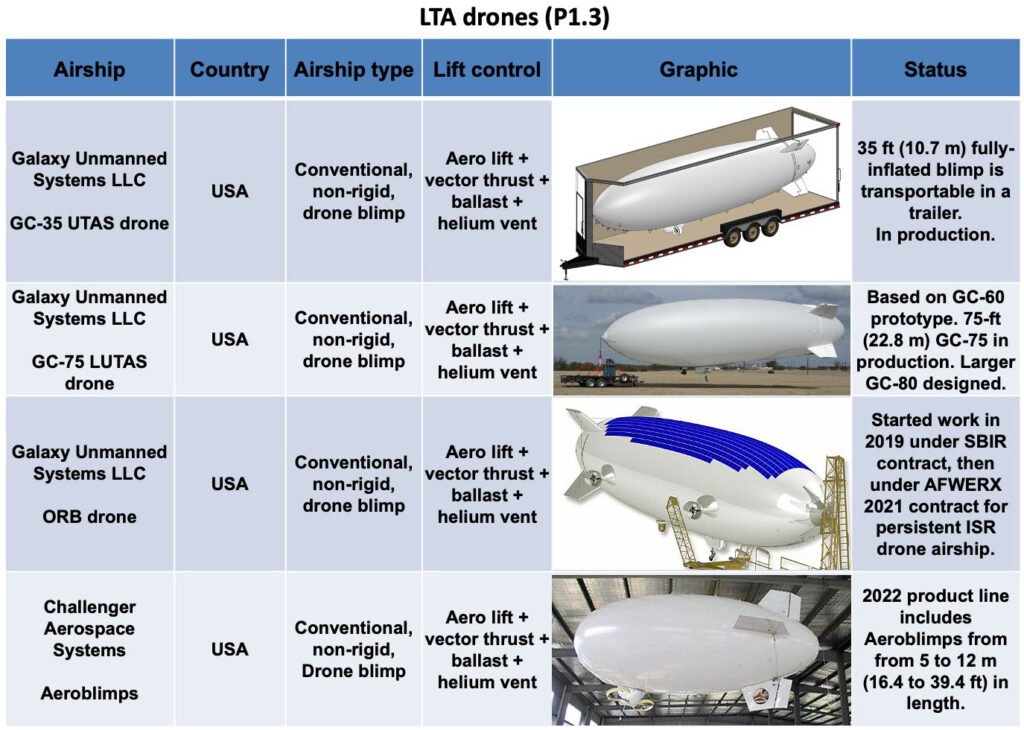

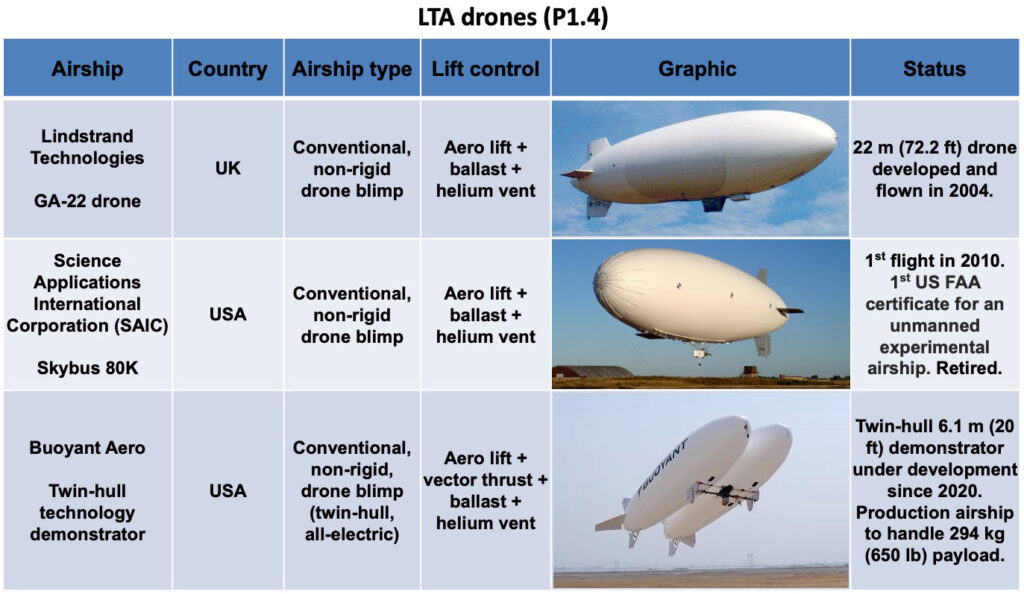

5.9 LTA drones

LTA drones are uncrewed airships that may be flown by remote control or by onboard control systems with varying degrees of autonomy. Such drones are being developed worldwide. Many LTA drones are small, conventional, elliptical or cylindrical hull airships. However, other designs, including twin-hull, spherical, lenticular and inflated delta wing have been developed and flown. Many are all-electric, and some have a photovoltaic solar array to help increase their range and operational flexibility.

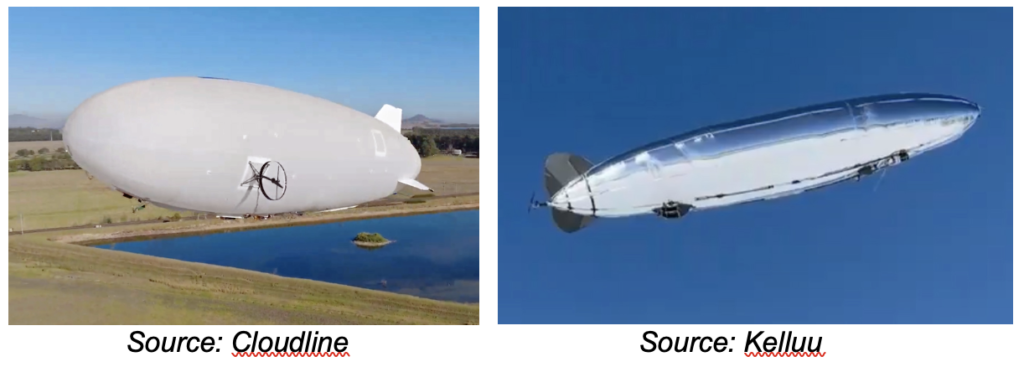

Two examples of modern, autonomous, all-electric LTA drones are the Cloudline cargo drone developed in South Africa and being operationally tested since mid-2023, and Kelluu’s persistent aerial monitoring drone developed and being tested in Finland, along with an information management infrastructure for rapidly delivering processed data to clients.

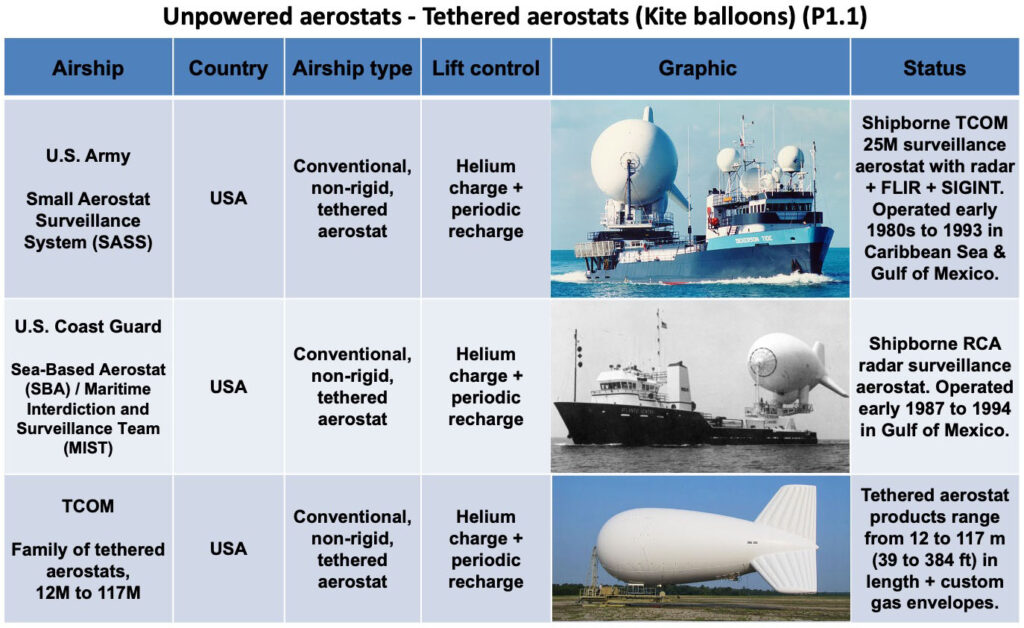

5.10 Unpowered aerostats

Unpowered aerostats include tethered and free-flying balloons used in a wide variety of applications. These vehicles are not “airships.”

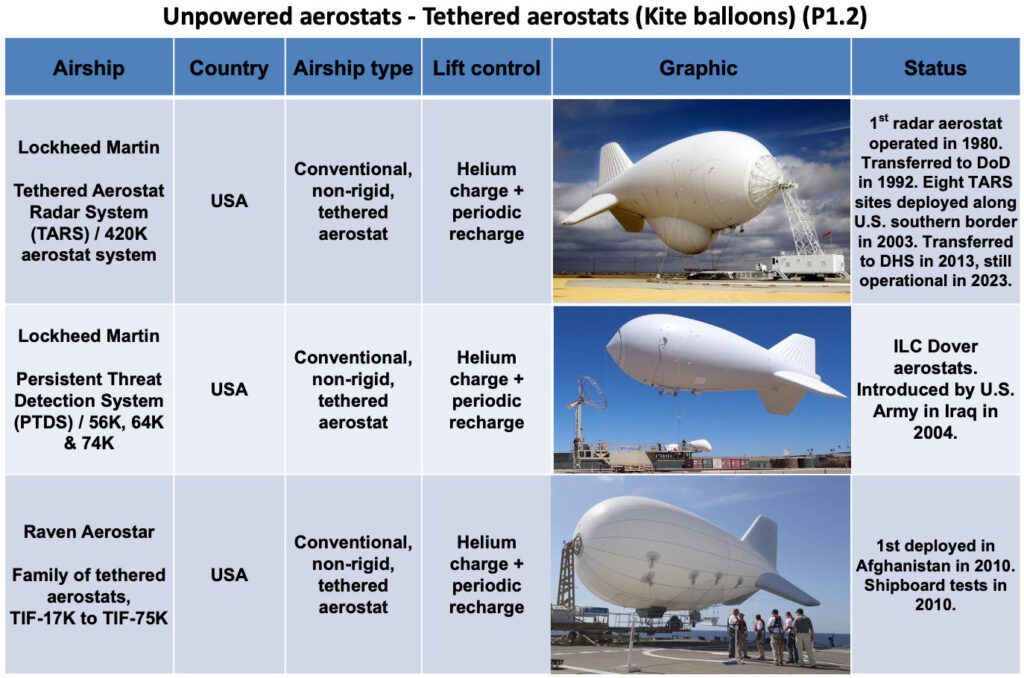

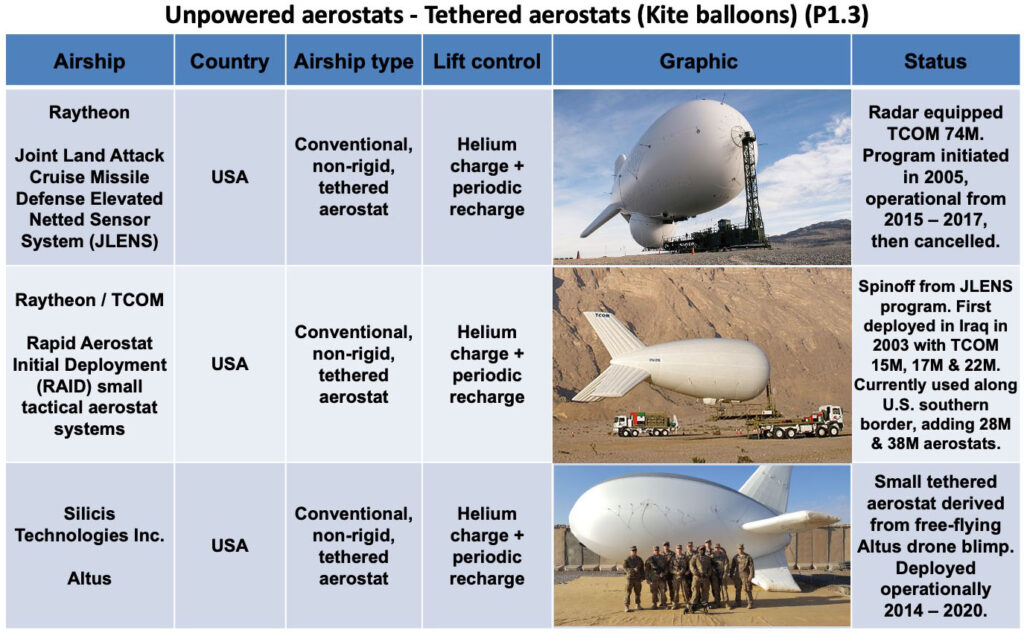

Tethered aerostats (kite balloons)

Many firms offer tethered aerostats for missions such as persistent surveillance and environmental monitoring, with instruments carried on the aerostat to an operating altitudes ranging from of several hundreds to several thousands of meters. The tether may be a simple steel or composite material cable (i.e., Kevlar), or it may be a powered tether that delivers electrical power to aerostat and payload systems and establishes a secure fiber optic data link between the aerostat and its ground station.

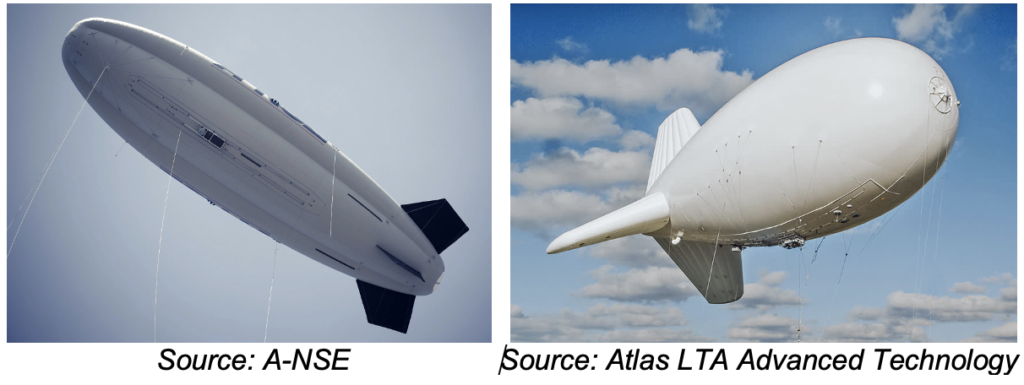

Examples are the T-C350 from the French firm A-NSE and the medium volume tethered aerostat from the Israeli firm Atlas LTA Advanced Technology.

Tethered manned aerostats

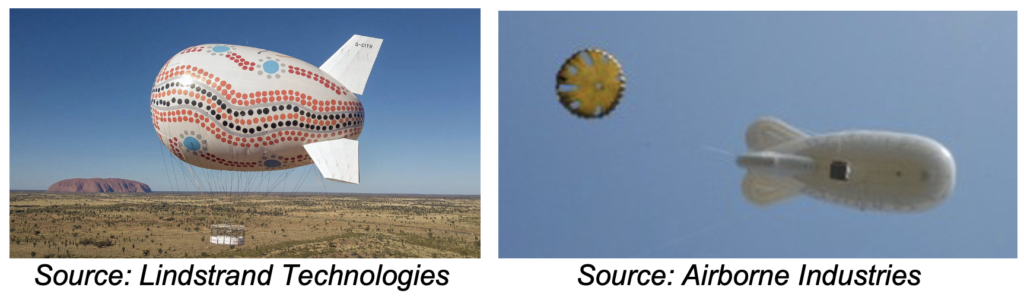

Tethered manned aerostats commonly are used in two application, as tourist sightseeing balloons and as parachute training balloons. Both applications require flying at relatively low altitude (305 m / 1,000 ft) with up to 30 tourist passengers or 8 – 10 parachute trainees. Spherical balloons are common for tourist flights. The latest Lindstrand manned aerostat has a more aerodynamic shape, like many unmanned tethered aerostats, and is able to operate in stronger wind conditions than a spherical manned aerostat.

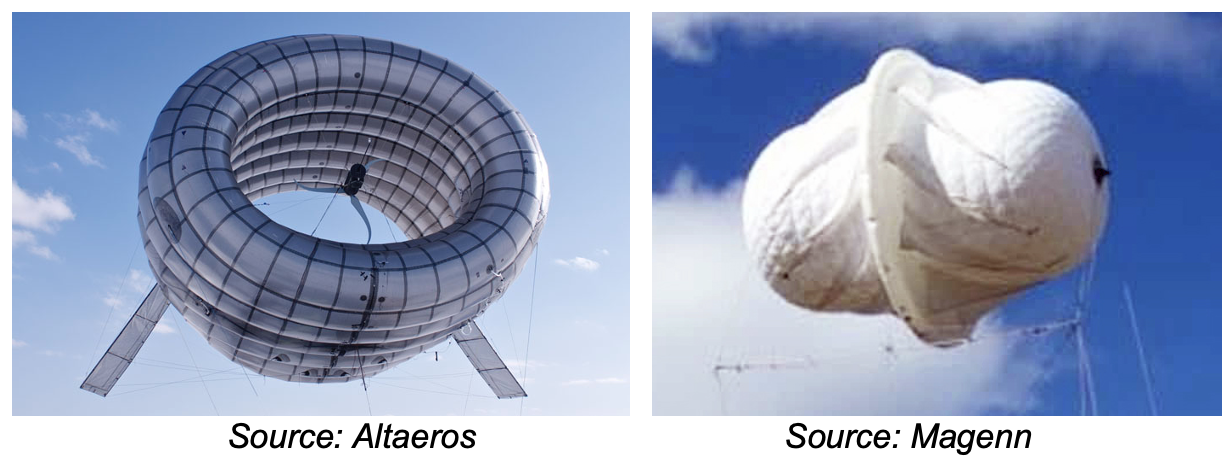

Tethered LTA wind turbines

Tethered buoyant wind turbines operate at altitudes of hundreds to thousands of feet above the ground, where stronger prevailing winds offer more energy for harvesting than at ground level. These tethered aerostats (kite balloons) carry one or more compact, wind-driven electric power generating systems that deliver power via the tether to a substation on the ground, and then onward to a regional electrical grid.

Two examples that have been tried, but not (yet) commercialized, are the Altaeros Energies BAT and the Magenn Air Rotor System (MARS).

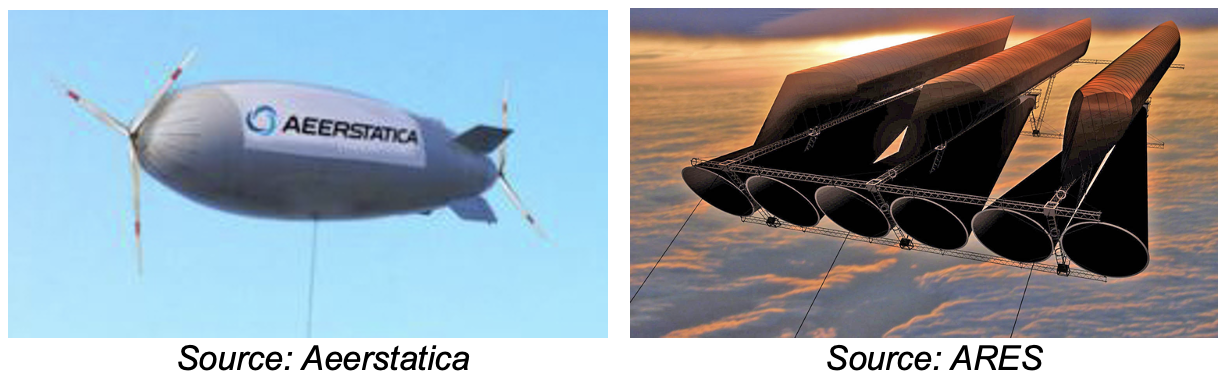

New, but untried airborne wind turbine systems are being developed in 2023 by Aeerstatica Energy Airships and by AirbineTM Renewable Energy Systems (ARES).

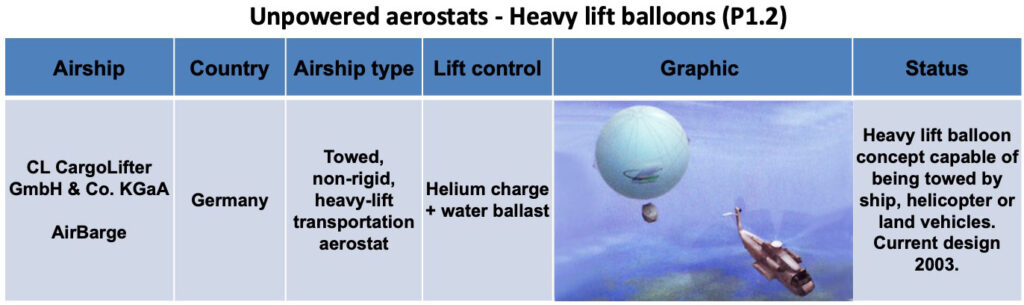

Tethered heavy lifter balloons

Another tethered aerostat application is as a heavy load lifter. In this application, the aerostat may be tethered at a fixed site to function as an heavy lift crane, replacing a conventional construction crane. The tethered aerostat may be designed for a mobile application, lifting a payload and being towed to a delivery site by a vehicle on the ground, a helicopter or by some other means.

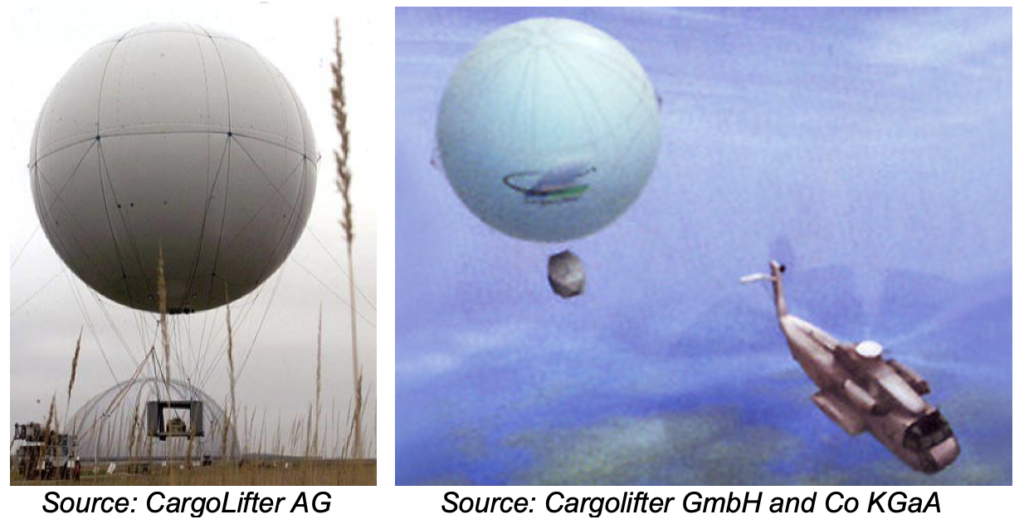

Examples are the German CargoLifter AG CL75-AC Air Crane, which flew in 2002, and AirBarge designed by the successor firm, CL Cargolifter GmbH and Co KGaA.

Hybrid tethered aerostat / free-flying powered airships

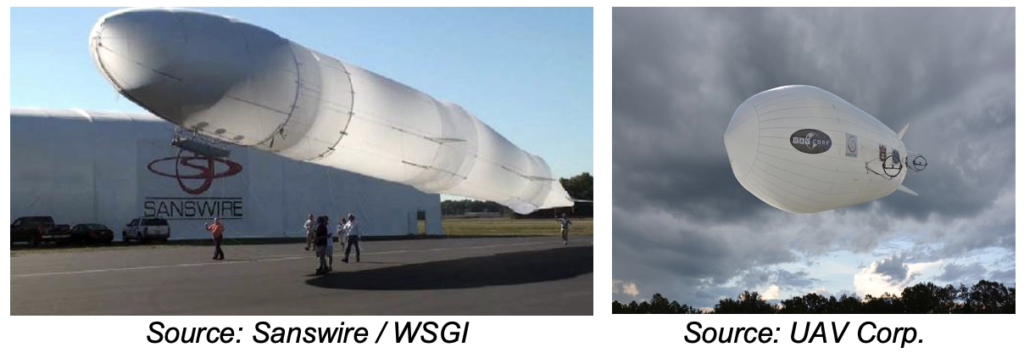

Some aerostats are designed to operate on a tether and, on command, detach and continue the mission as a free-flying airship. This hybrid vehicle can operate on station for a long period of time as an tethered aerostat until something of interest is detected. Then the vehicle detaches and flies away to provide a closeup investigation at the point of interest.

Examples are the Sanswire / WSGI Argus One Hybrid aerostat / UAV and the Detachable Airship from a Tether (DATT) being developed by UAV Corp.

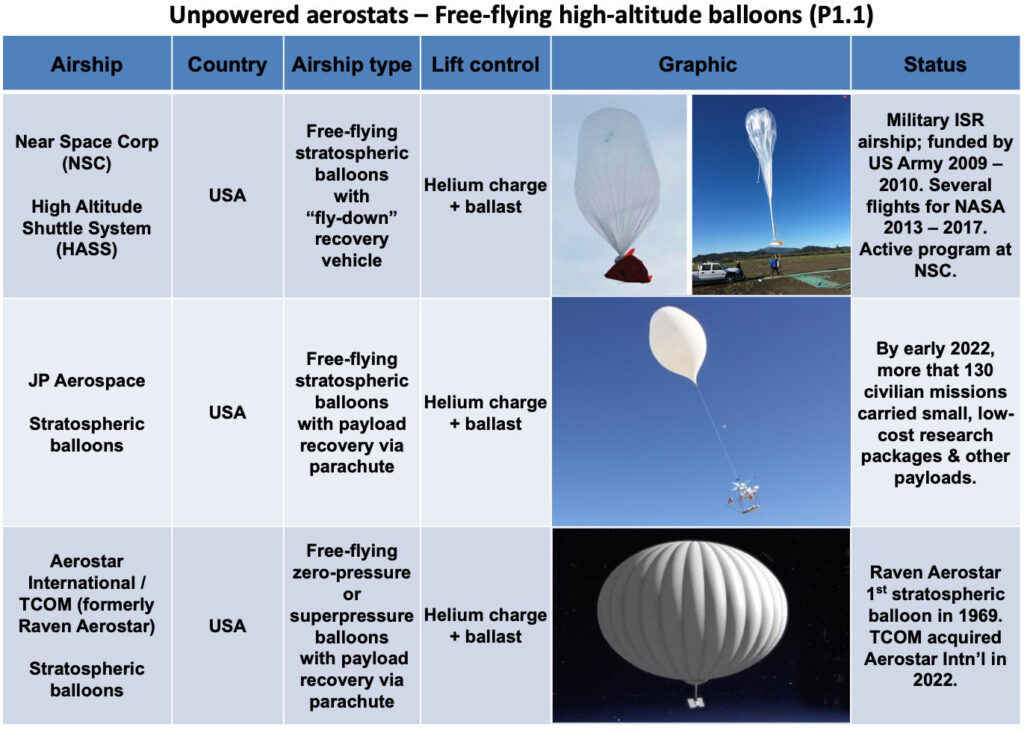

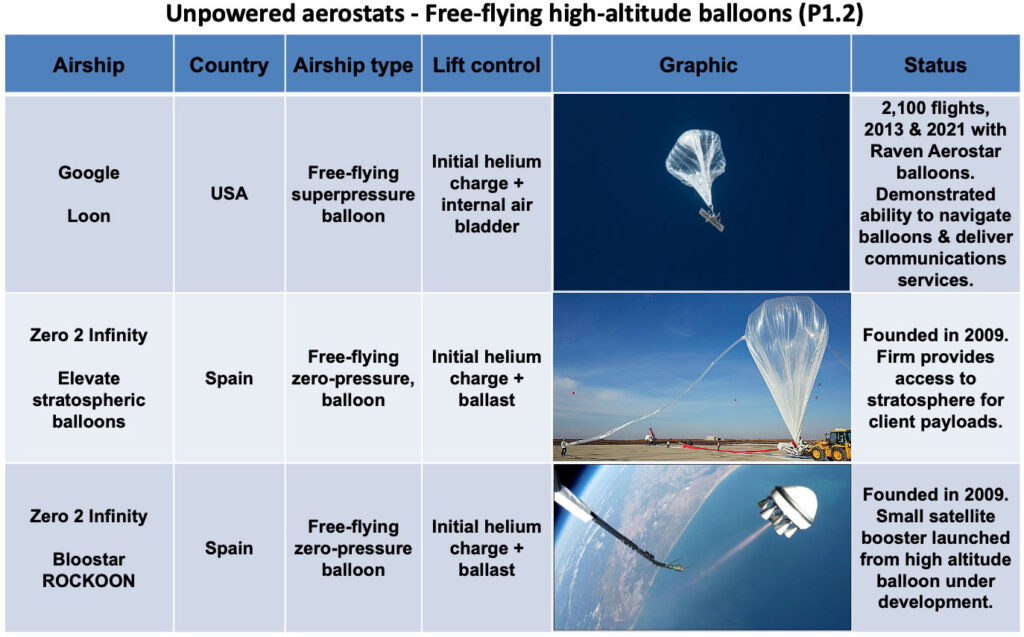

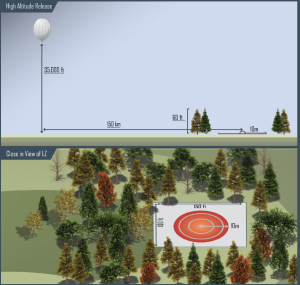

Free-flying, high-altitude balloons

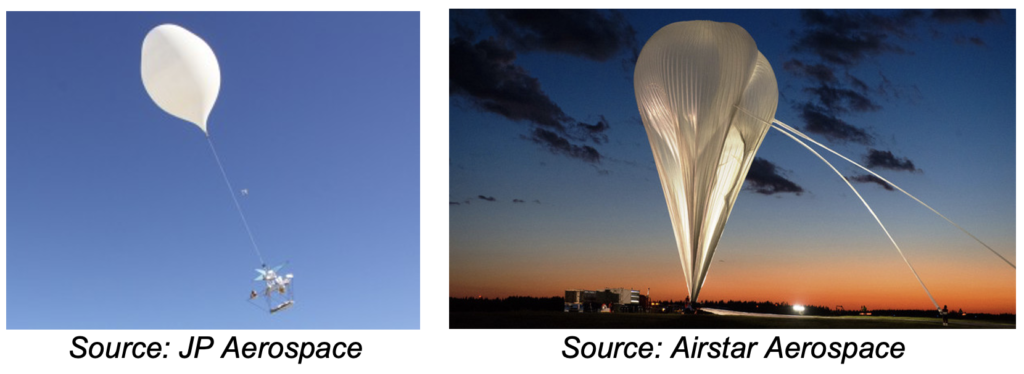

Free-flying balloons can provide relatively low-cost access to the stratosphere. Zero-pressure balloons can lift large payloads (up to thousands of kilograms) to altitudes up to about 45,000 meters (147,638 ft / 28.0 miles) on missions lasting up to a week. Superpressure balloons can remain aloft much longer than zero-pressure balloons and can be deployed on missions of several months, but with smaller payloads. Several firms offer stratospheric assess with free-flying balloons, including Airstar Aerospace, Aerostar/TCOM, Zero 2 Infinity and JP Aerospace.

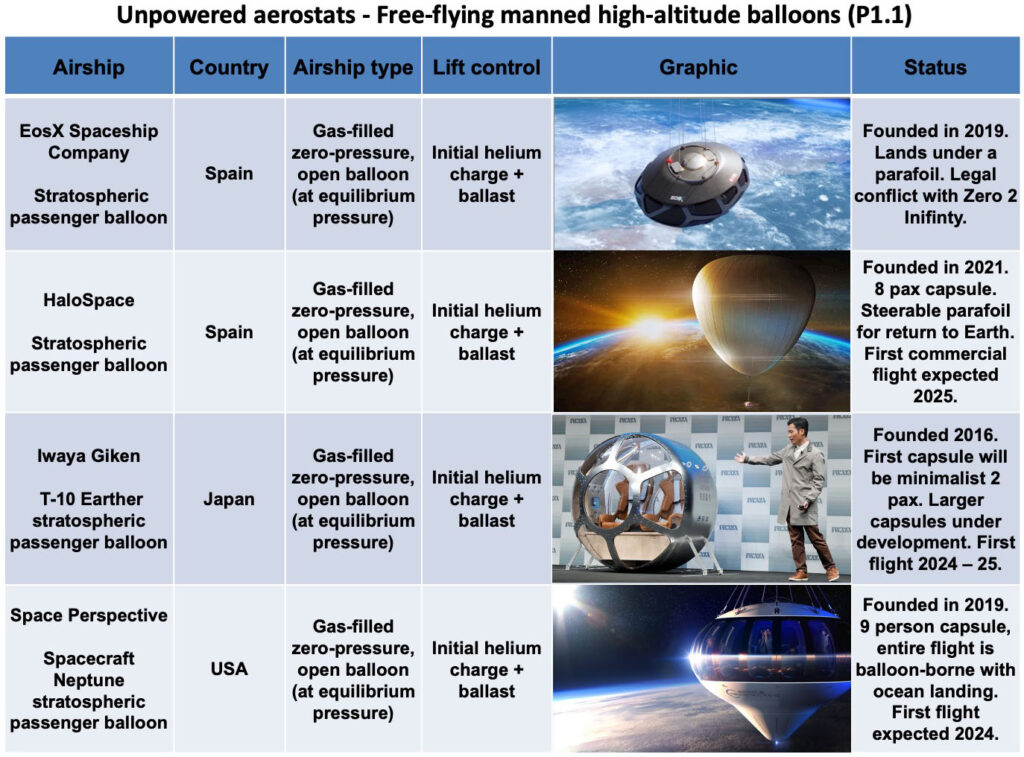

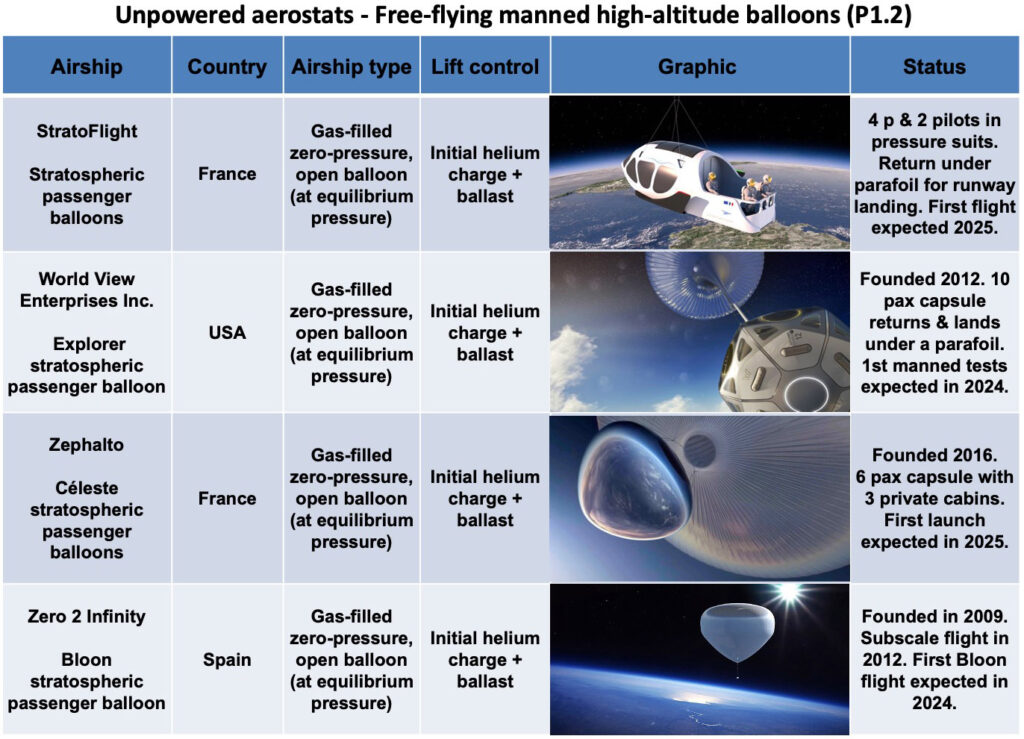

Free-flying, manned, high-altitude balloons

There are many firms developing pressurized passenger capsules to carry “space tourists” to altitudes up to about 40 km (25 miles) under very large stratospheric balloons. These flights will include a couple of hours to view the Earth from maximum altitude. After initial descent under the balloon, most of the capsules return to Earth under a parachute or parafoil with a landing on the ground or in the sea. The balloon typically is not recovered. Full-scale system test flights are expected to begin in 2024, with initial passenger flights by 2025.

6. How does an airship pick up and deliver a heavy load?

The term “load exchange” refers to the pickup and delivery of cargo by an airship, with or without an exchange of external ballast to compensate for the mass of cargo being moved on or off the airship. This isn’t a simple problem to solve.

The problem of buoyancy control

In Jeanne Marie Laskas’ article, Igor Pasternak, CEO of airship manufacturer Worldwide Aeros Corp. (Aeros), commented on the common problem facing all airships when a heavy load is delivered:

“The biggest challenge in using lighter-than-air technology to lift hundreds of tons of cargo is not with the lifting itself—the larger the envelope of gas, the more you can lift—but with what occurs after you let the stuff go. ‘When I drop the cargo, what happens to the airship?’ Pasternak said. ‘It’s flying to the moon.’ An airship must take on ballast to compensate for the lost weight of the unloaded cargo, or a ground crew must hold it down with ropes.”

Among the many current designers and manufacturers of large airships, the matter of maintaining the airship’s net buoyancy within certain limits while loading and unloading cargo and passengers is handled in several different ways depending on the type of airship involved. Some load exchange solutions require ground infrastructure at fixed bases and/or temporary field sites for external ballast handling, while others require no external ballasting infrastructure and instead use systems aboard the airship to adjust buoyancy to match current needs or provide vectored thrust (or suction) to temporarily counteract the excess buoyancy. The solution chosen for managing airship buoyancy during a load exchange strongly influences how an airship can be operationally employed and where it can pickup and deliver its payload.

Additional problems for airborne load exchanges

Several current designers and manufacturers of large airships report that their airships will have the ability to conduct airborne load exchanges of cargo from a hovering airship. Jeremy Fitton, the Director of SkyLifter, Ltd., described the key issues affecting a precision load exchange executed by a hovering airship as follows:

“The buoyancy management element of (an airborne) load-exchange is not the main control problem for airships. Keeping the aircraft in a geo-stationary position – in relation to the payload on the ground – is the main problem, of which buoyancy is a component.”

The matters of precisely maintaining the airship’s geo-stationary position throughout an airborne load exchange and controlling the heading of the airship and the suspended load are handled in different ways depending on the type of airship involved. The time required to accomplish the airborne load exchange can be many minutes or much longer, depending on the weight of the cargo being picked up or delivered and the time it takes for the airship to adjust its buoyancy for its new loaded or unloaded condition. Most of the airships offering an airborne load exchange capability are asymmetrical (i.e., conventional “cigar shaped” or hybrid aerobody-shaped) and must point their nose into the wind during an airborne load exchange. Their asymmetrical shape makes these airships vulnerable to wind shifts during the load exchange. The changing cross-sectional area exposed to the wind complicates the matter of maintaining a precise geo-position with an array of vectoring thrusters.

During such a delivery in variable winds, even with precise geo-positioning over the destination, the variable wind direction may require the hovering airship to change its heading slightly to point into the wind. This can create a significant hazard on the ground, especially when long items, such as a wind turbine blade or long pipe segment are being delivered. For example, the longest wind turbine blade currently in production is the GE Haliade-X intended for off-shore wind turbine installations. This one-piece blade is 107 meter (351 ft) long. A two degree change in airship heading could sweep the long end of the blade more than three meters (10 feet), which could be hazardous to people and structures on the ground.

Regulatory requirements pertaining to load exchanges

The German / Netherlands “Transport Airship Requirements” (TAR), includes the following requirement for load exchanges in TAR 80, “Loading / Unloading”:

(c) During any cargo exchange…the airship must be capable of achieving a safe free flight condition within a time period short enough to recover from a potentially hazardous condition.”

Similar requirements exist in the EASA proposed Special Conditions published in February 2021, in SC GAS.2125, “Loading / Unloading.”

These requirements will be a particular challenge for airships designed to execute an airborne load exchange from a hovering airship.

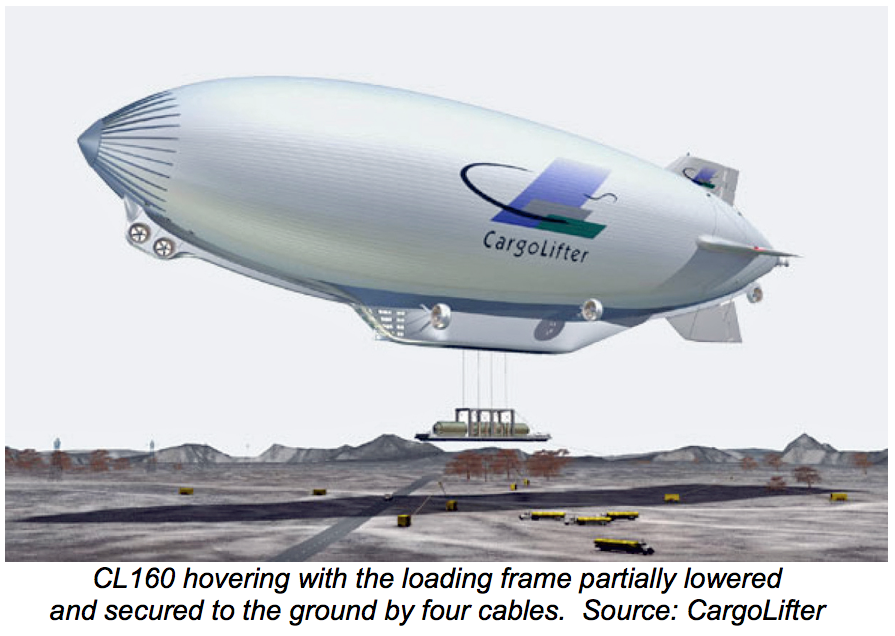

The CargoLifter approach to an airborne load exchange

One early approach for delivering a load from a hovering airship was developed for the CargoLifter CL160. As described on the Aviation Technology website (https://www.aerospace-technology.com/projects/cargolifter/), the CL160 would have performed an in-flight delivery of cargo as follows:

“The airship hovers at about 100 m above the ground and a special loading frame, which is fixed during flight to the keel of the airship, is then rigged with four cable winches to the ground, a procedure which is to assure that the airship’s lifting gear stays exactly above the desired position. Ballast water is then pumped into tanks on the frame and the payload can be unloaded. The anchor lines are released and the frame is pulled back into the payload bay of the airship.”

In a 2002 test using the heavy-lift CargoLifter CL75 aerostat as an airship surrogate, a 55 metric ton German mine-clearing tank was loaded, lifted and discharged from the loading frame as water ballast was unloaded and later reloaded in approximately the same time it took to secure the tank in the carriage (several minutes). In this test, the 55 metric tons cargo was exchanged with about 55 cubic meters (1,766 cubic feet, 14,530 US gallons) of water ballast.

The SkyLifter approach to an airborne load exchange

One airship design, the SkyLifter, addresses the airborne load exchange issues with a symmetrical, disc-shaped hull that presents the same effective cross-sectional area to a wind coming from any direction. With the aid of cycloidal propellers, his airship is designed to move equally well in any direction (omni-directional), simplifying airship controls in changing wind conditions, and likely giving the SkyLifter an advantage over other designs in maintaining a precise geolocation above a site while conducting an airborne load exchange without the need for the system of ground tethers used by the CL160

Source: Skylifter (now Luffships Ltd.)

You’ll find more information on airship load exchange issues in a December 2017 paper by Charles Luffman, entitled, “A Dissertation on Buoyancy and Load Exchange for Heavy Airships (Rev. B)”, which is available at the following link: https://www.luffships.com/wp-content/uploads/2018/02/buoyancy_and_load_exchange.pdf

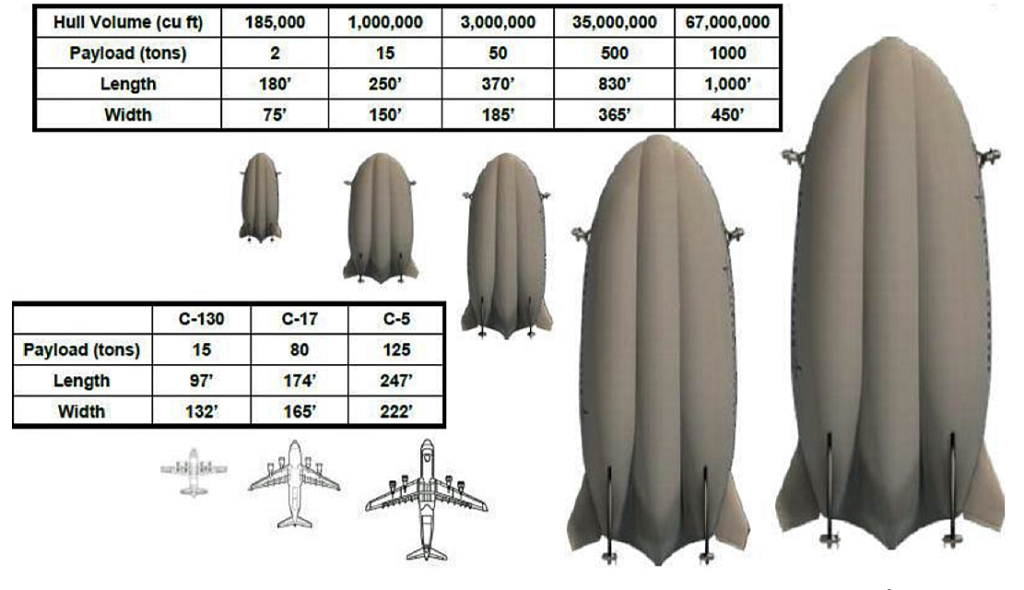

7. The scale of large cargo airships

Some of the advanced airship concepts being developed, especially for future heavy-lift cargo carriers, will result in extremely large air vehicles on a scale not seen since the heyday of the giant zeppelins in the 1930s. Consider the following semi-rigid hybrid airships shown to scale with contemporary US Air Force fixed-wing cargo aircraft.

Source: DoD 2012

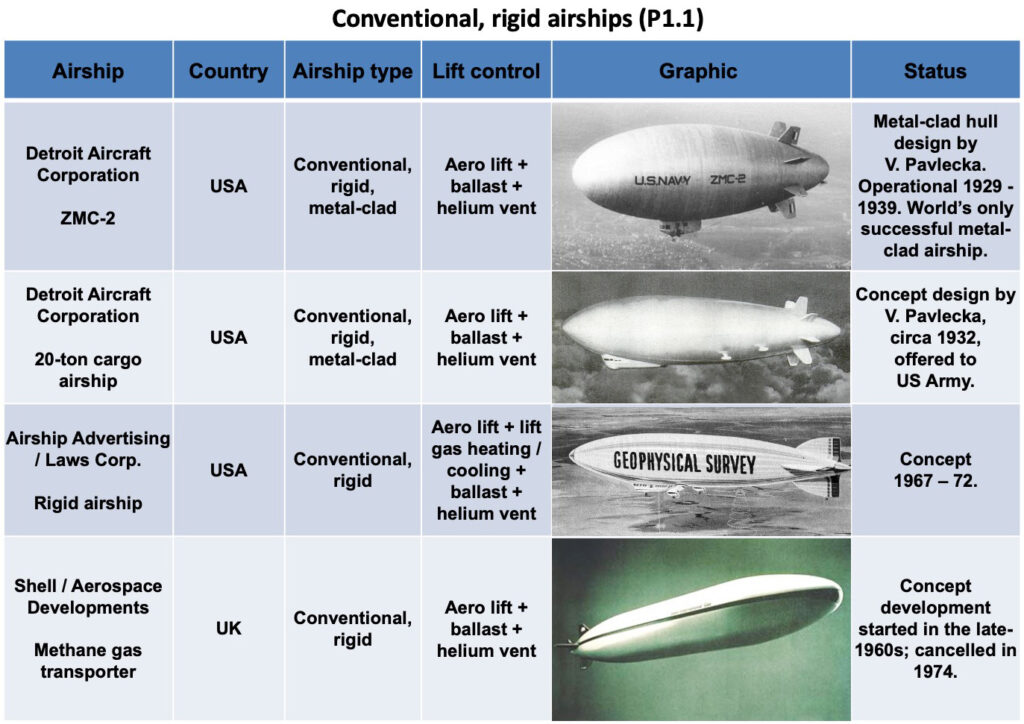

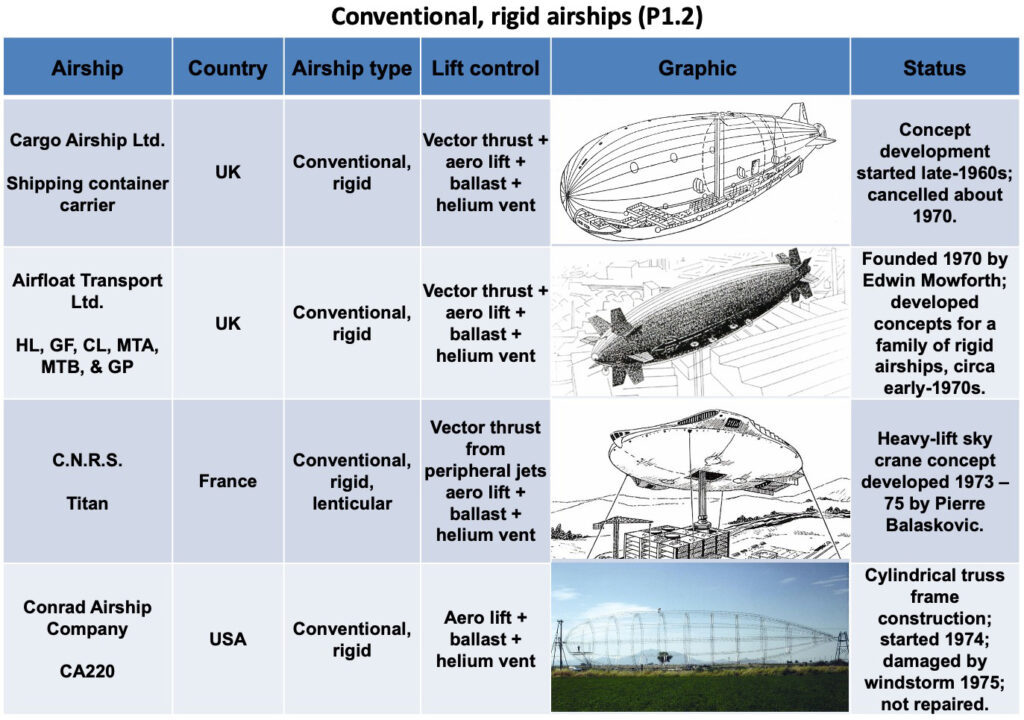

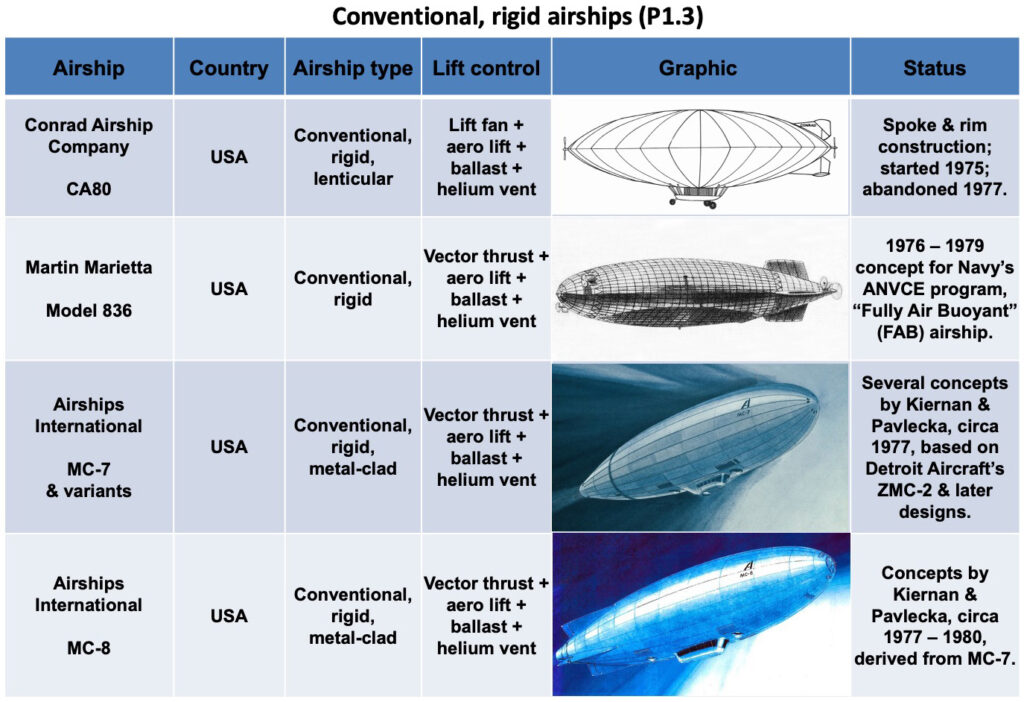

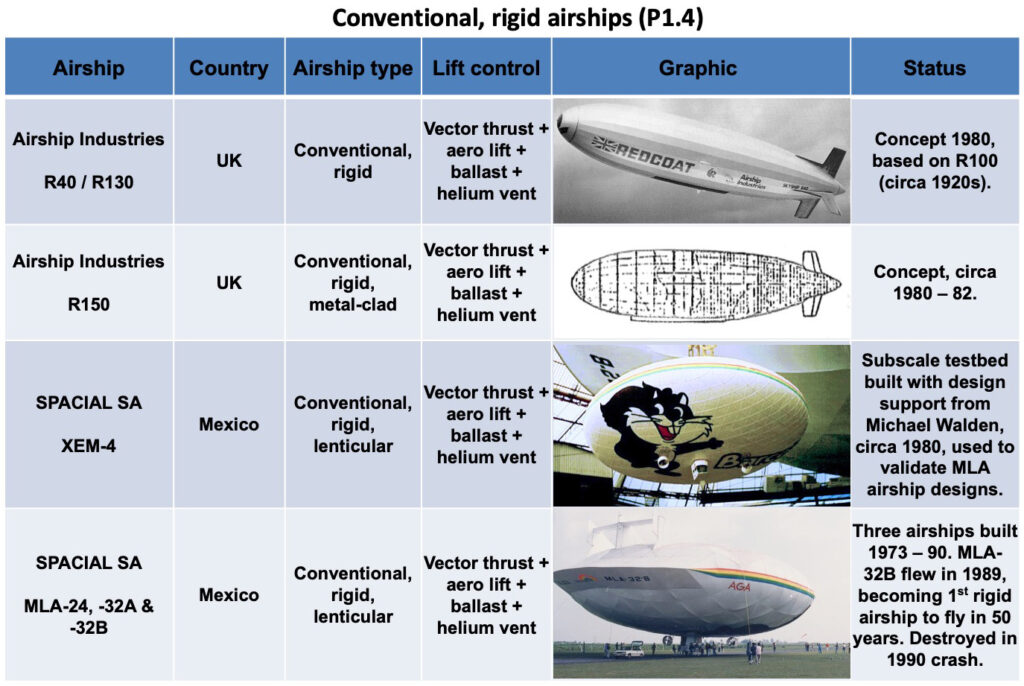

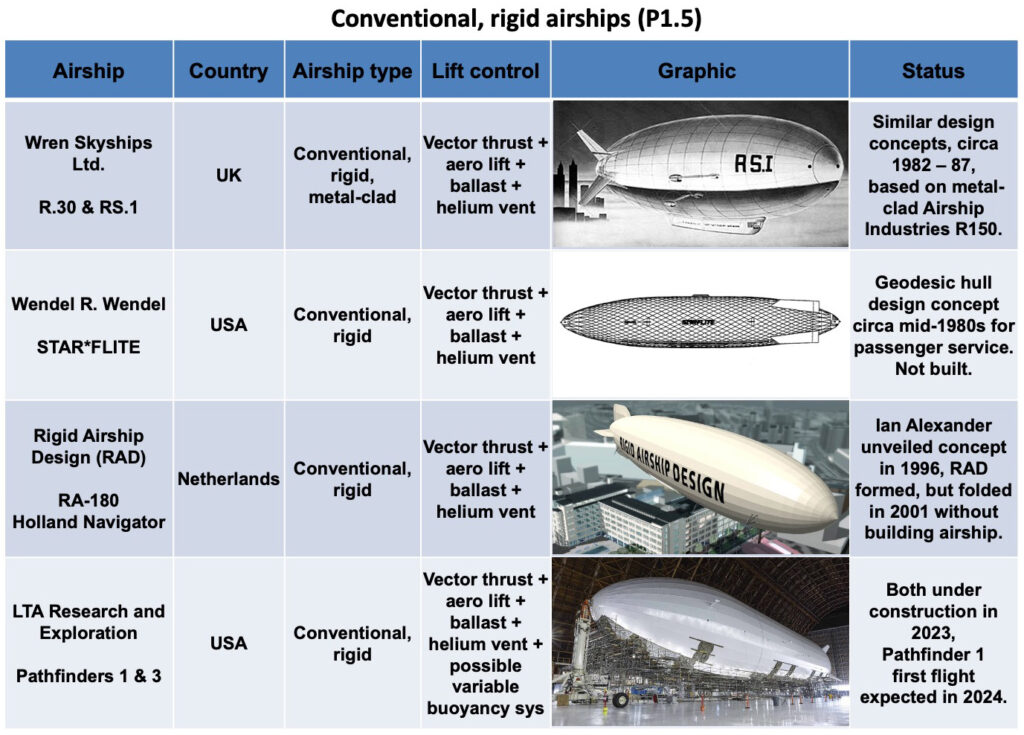

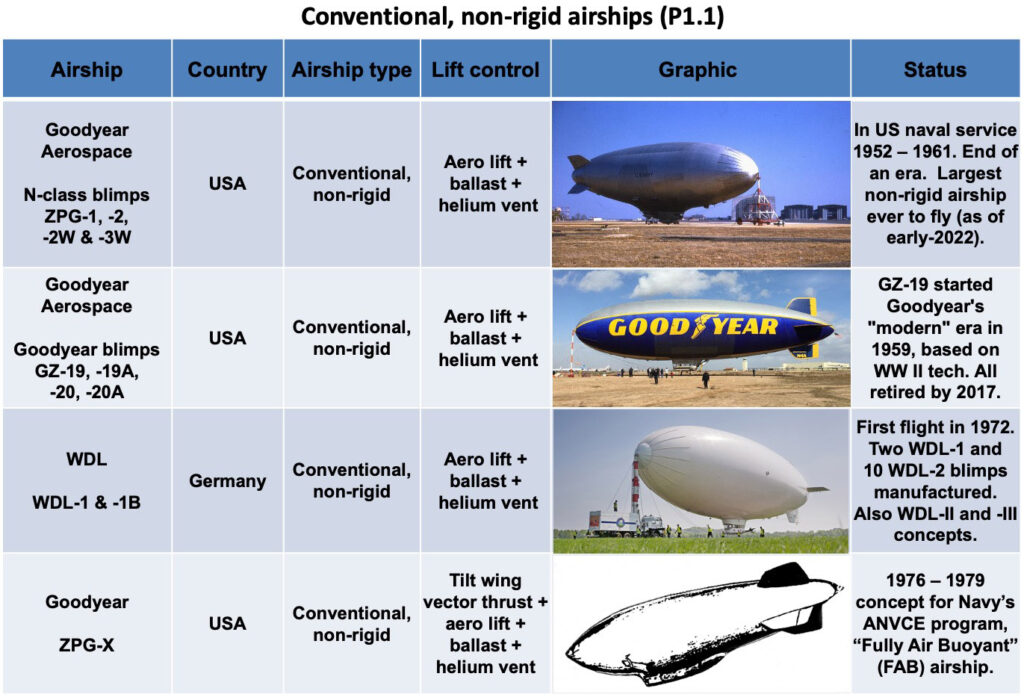

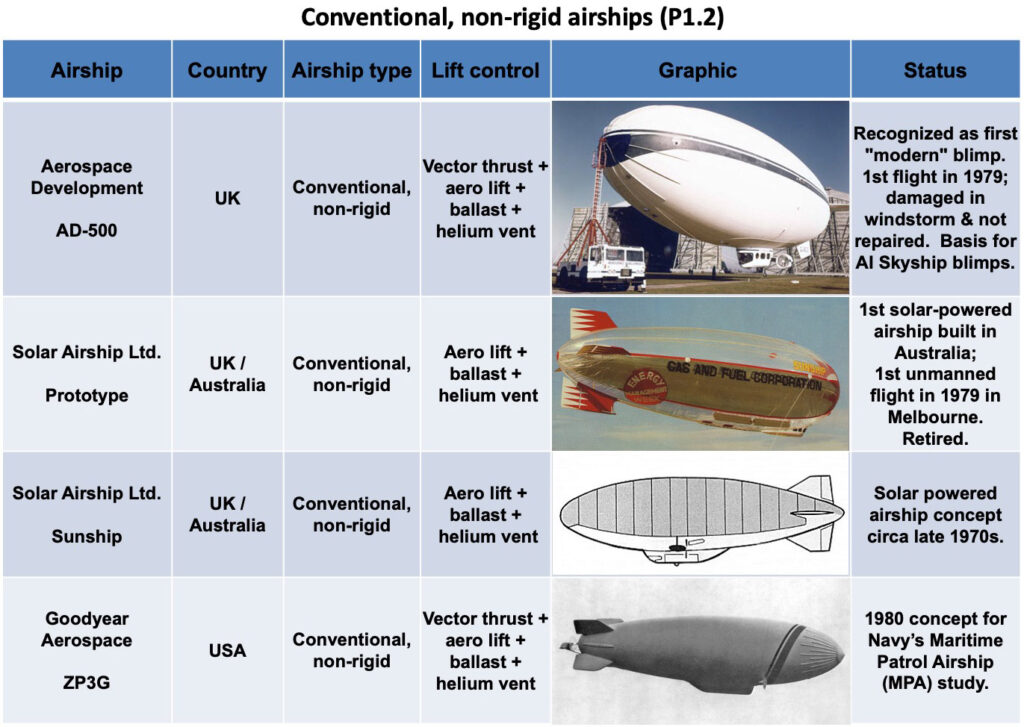

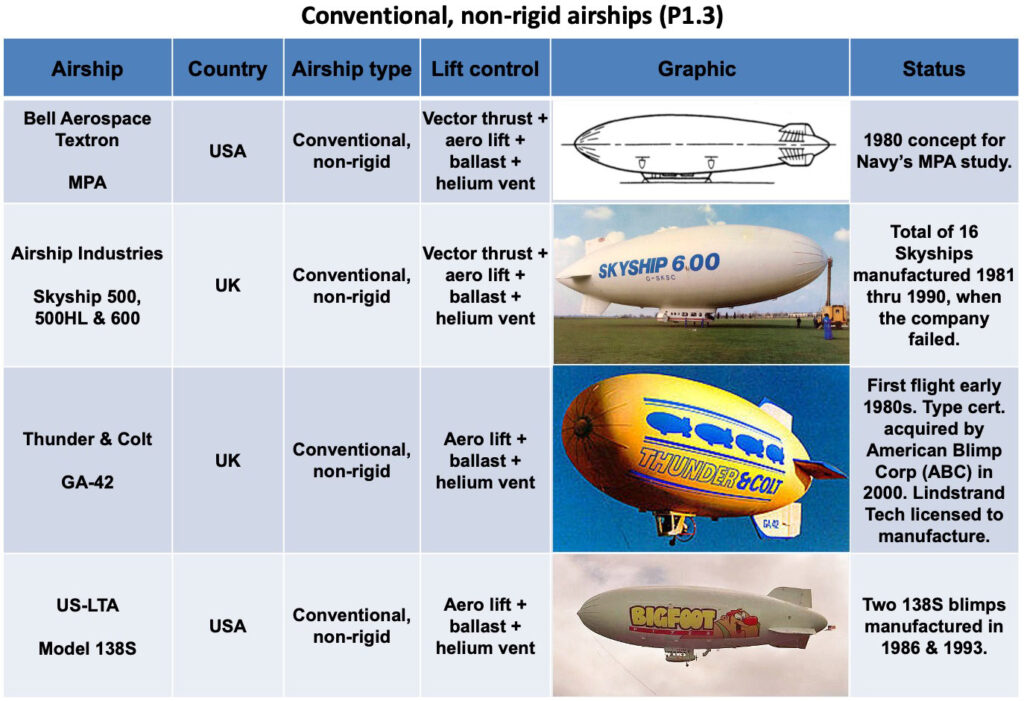

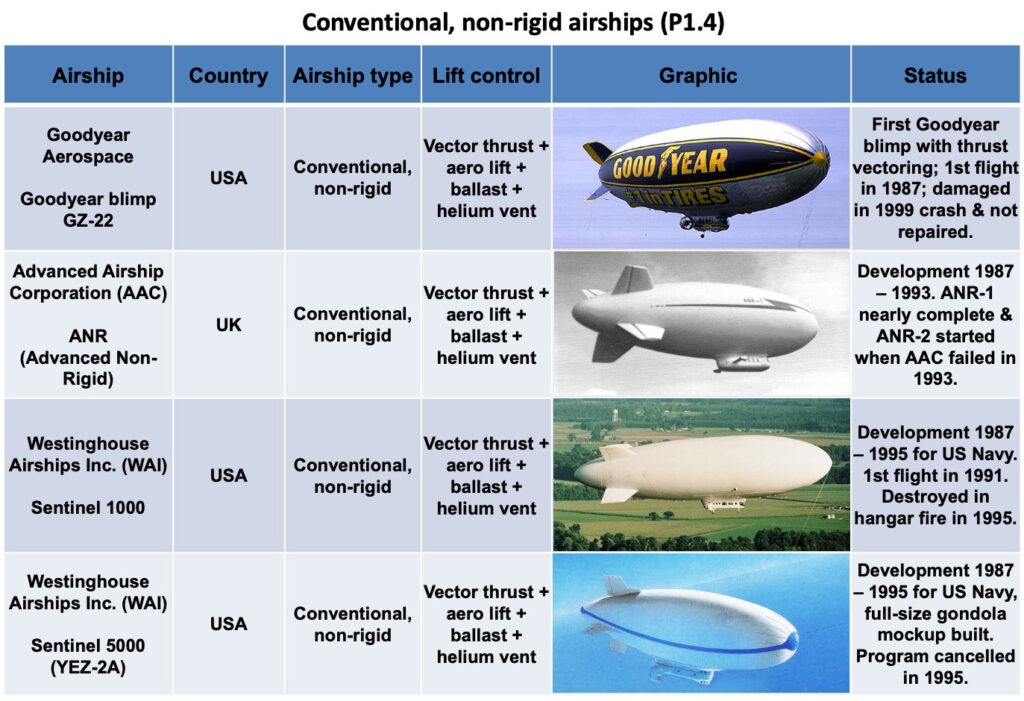

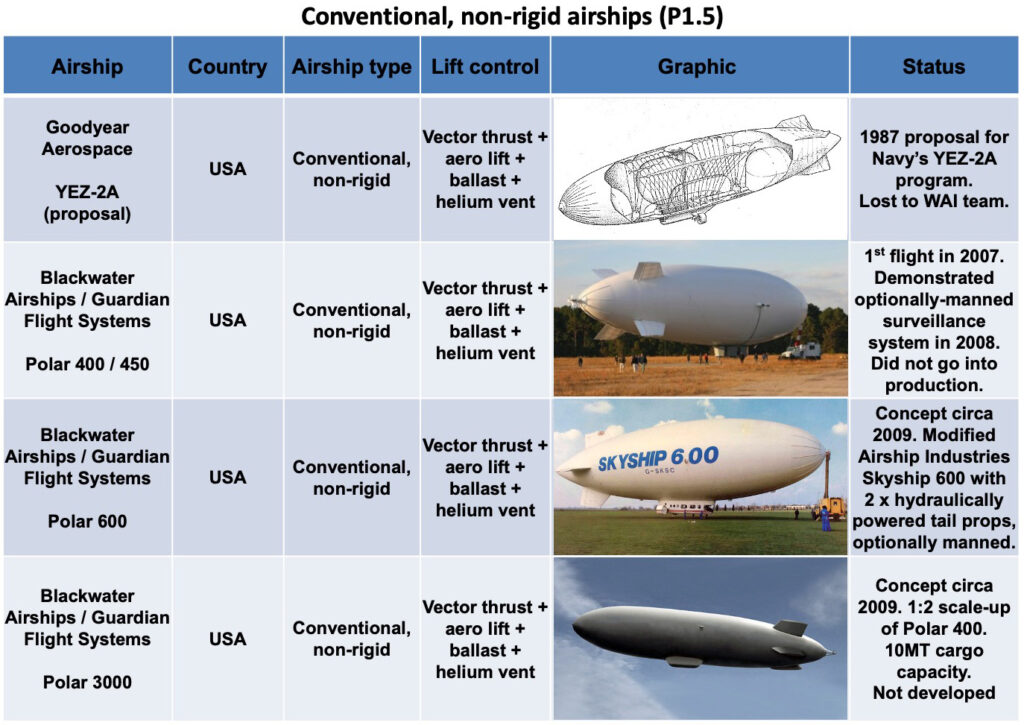

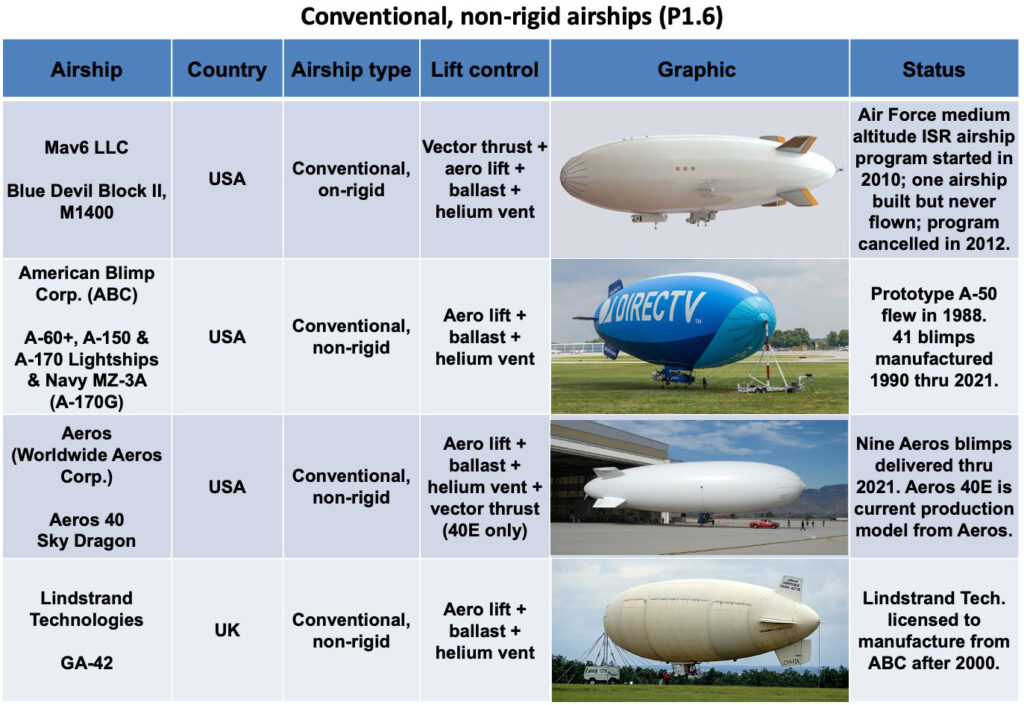

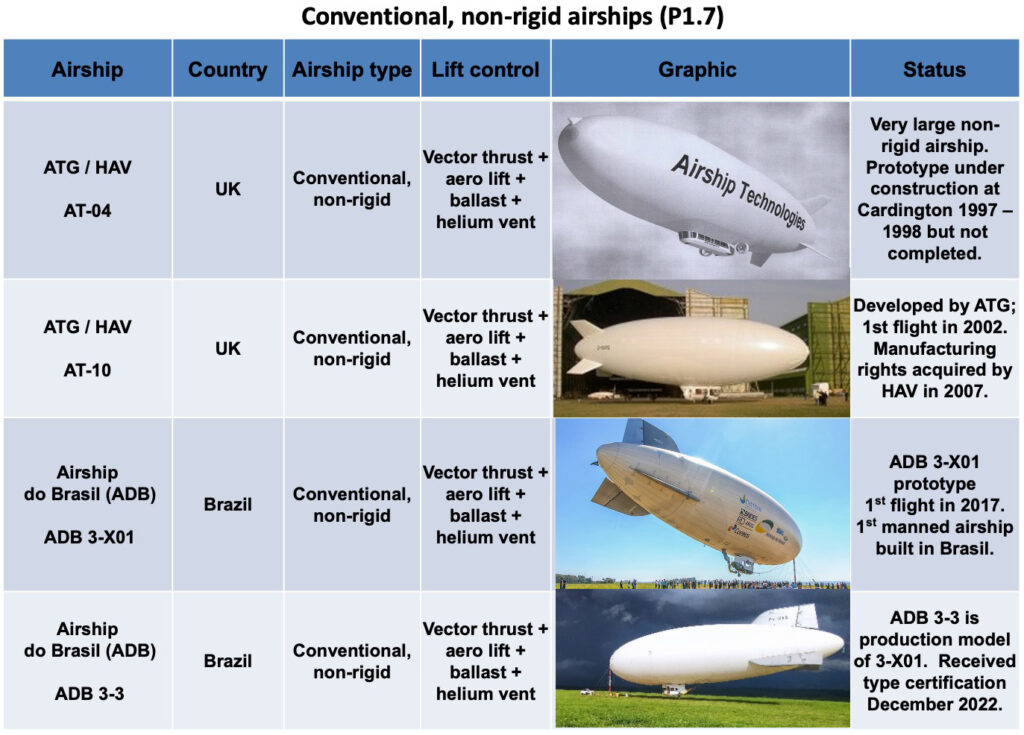

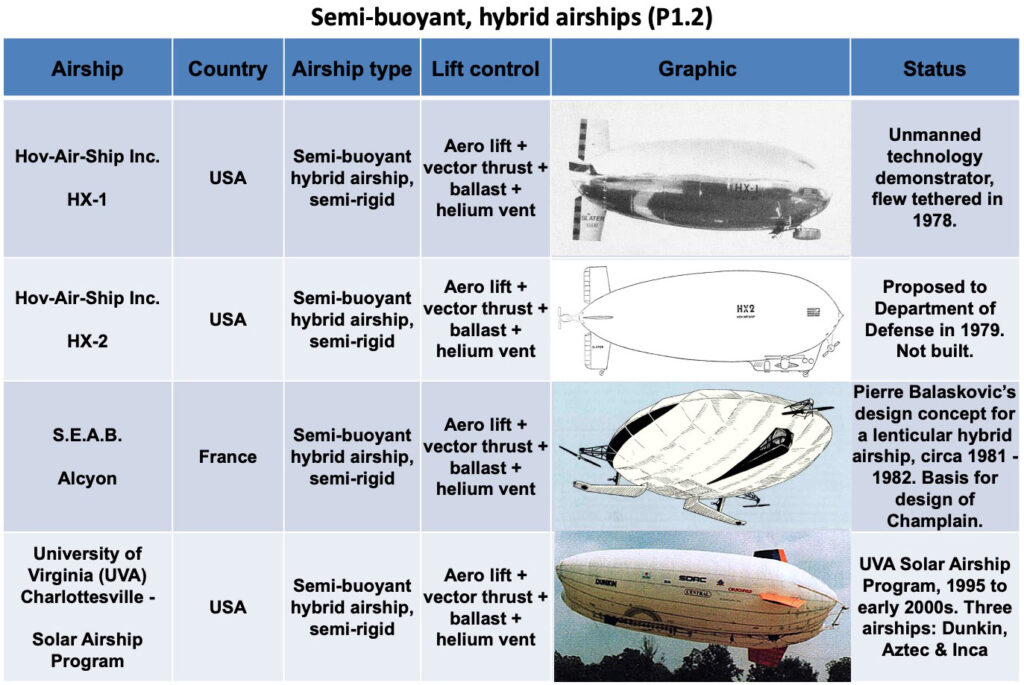

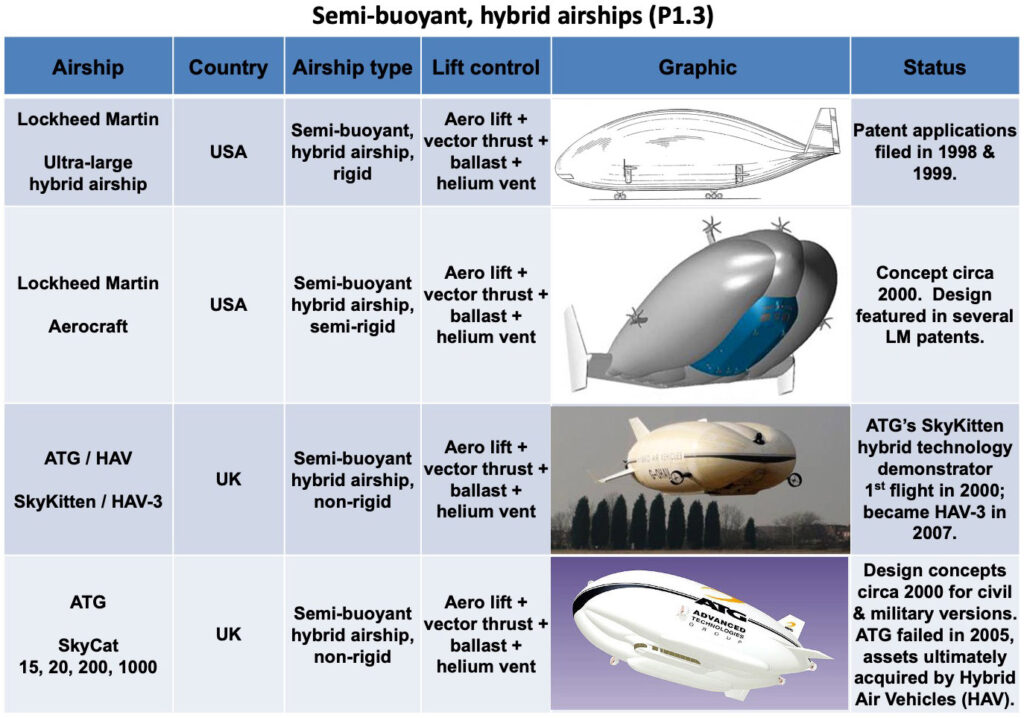

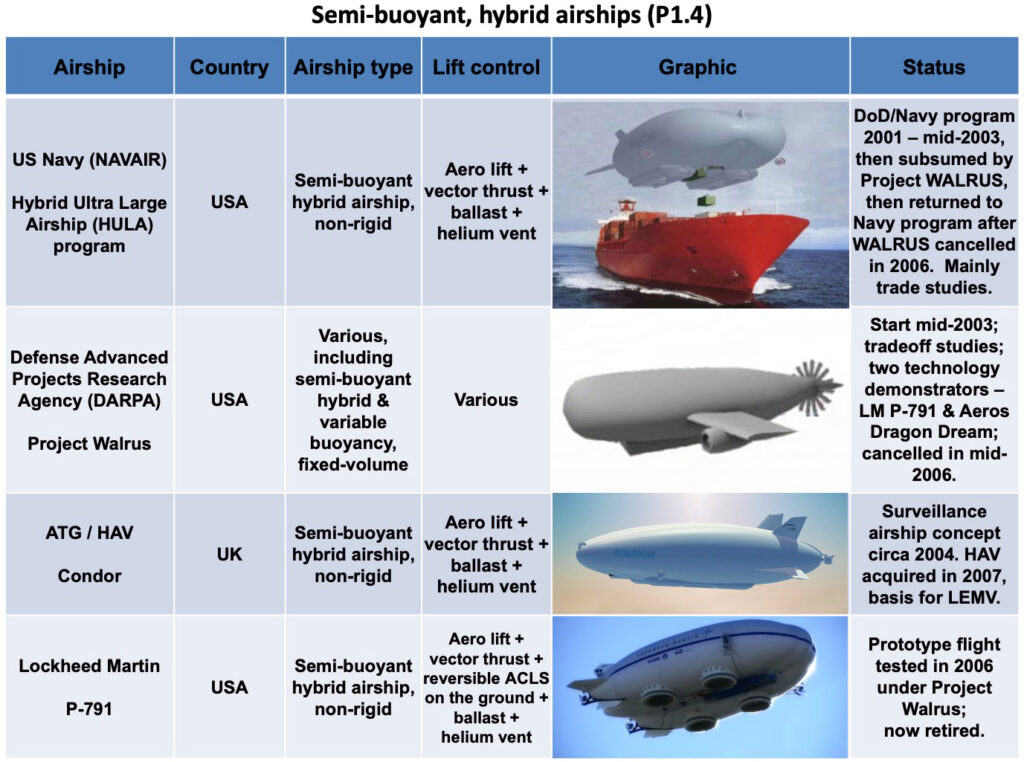

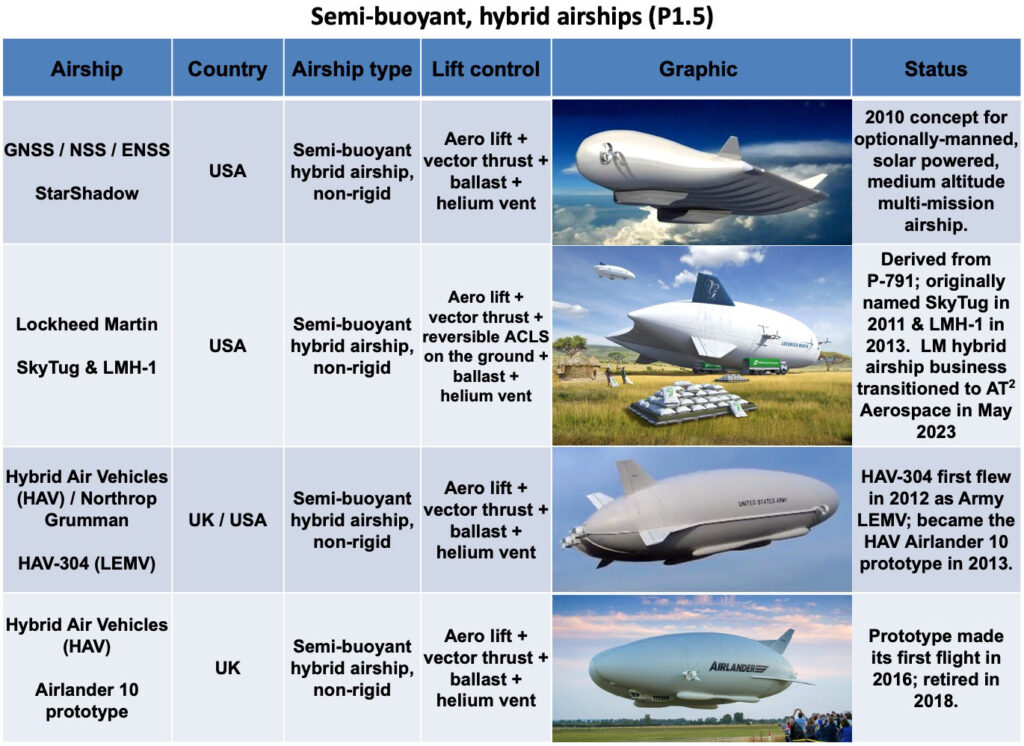

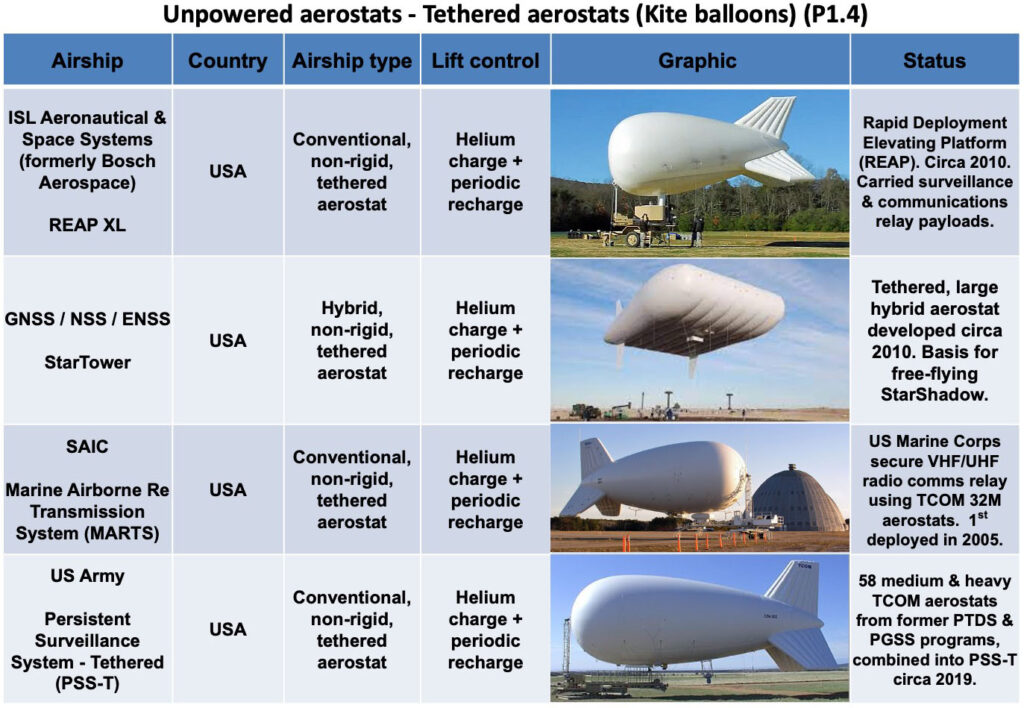

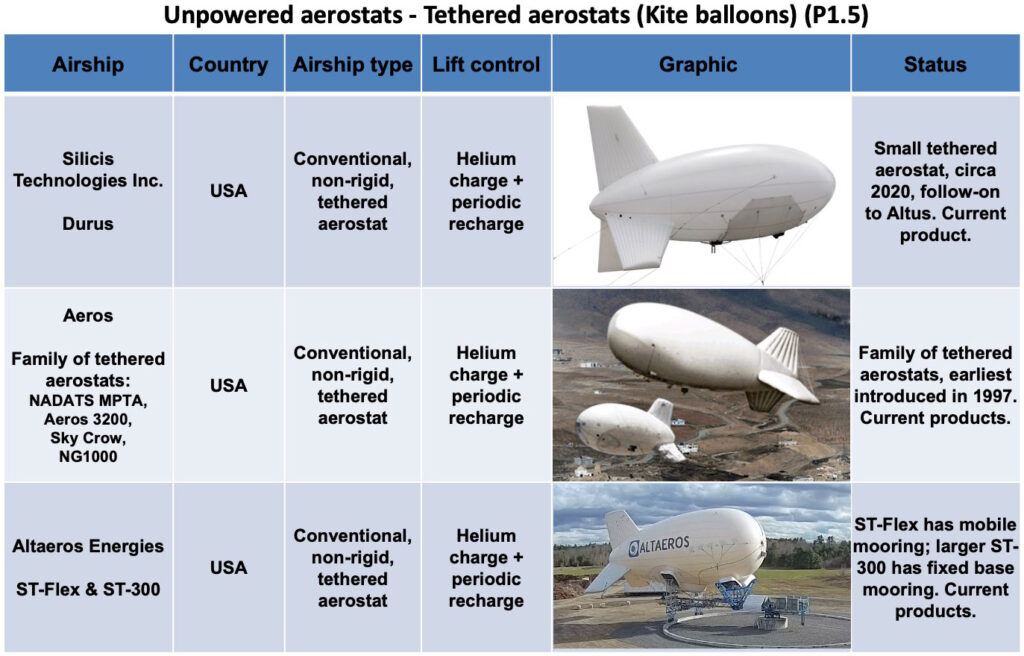

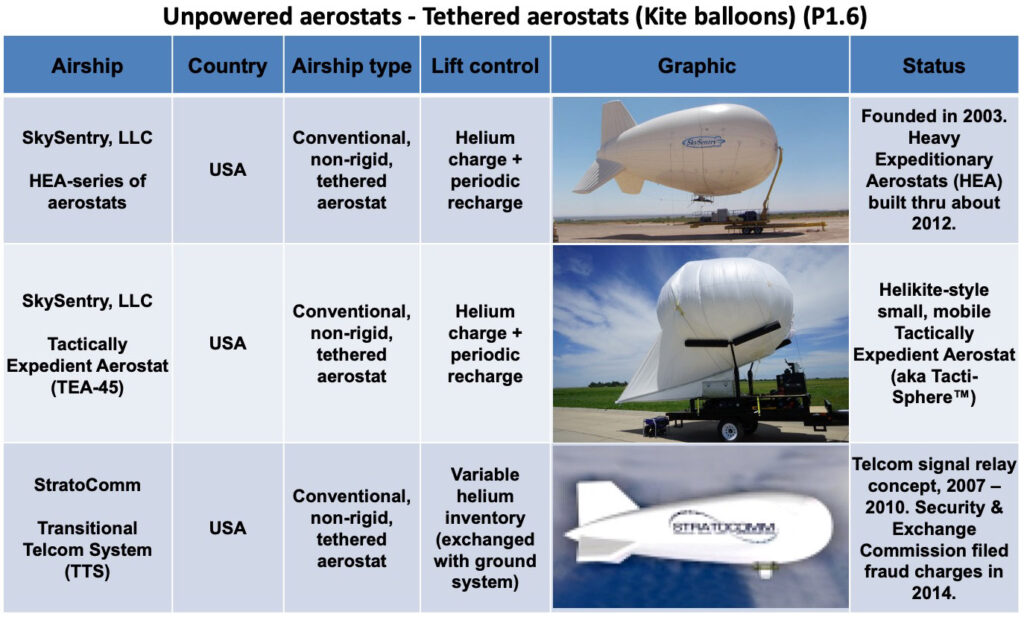

8. Graphic tables

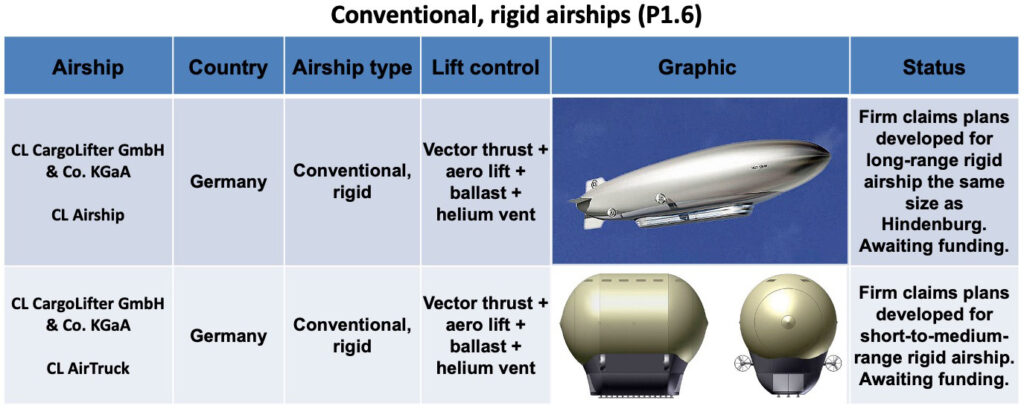

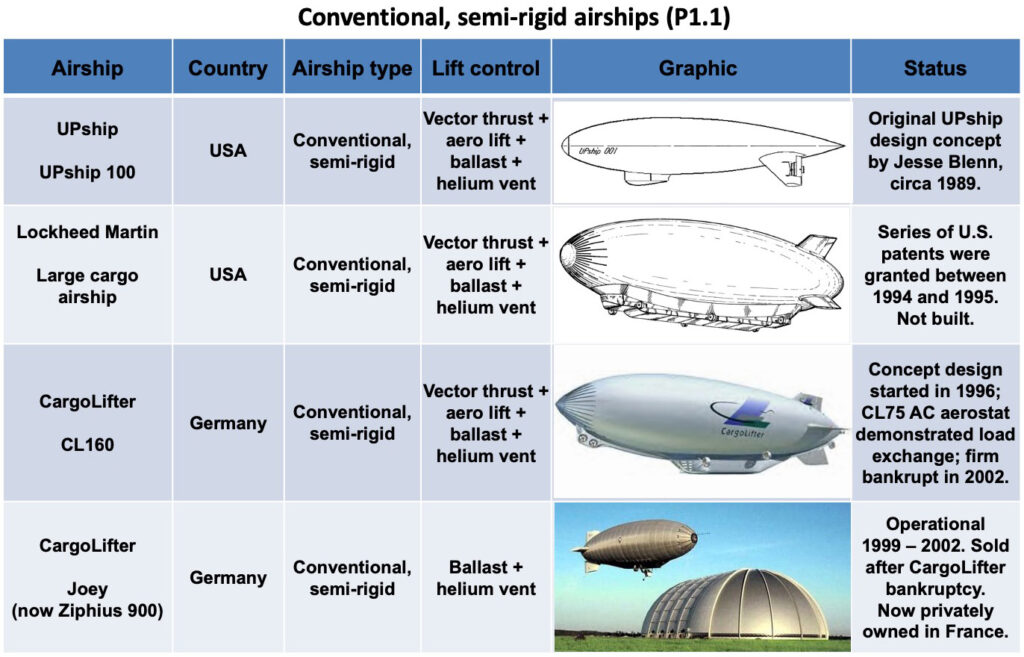

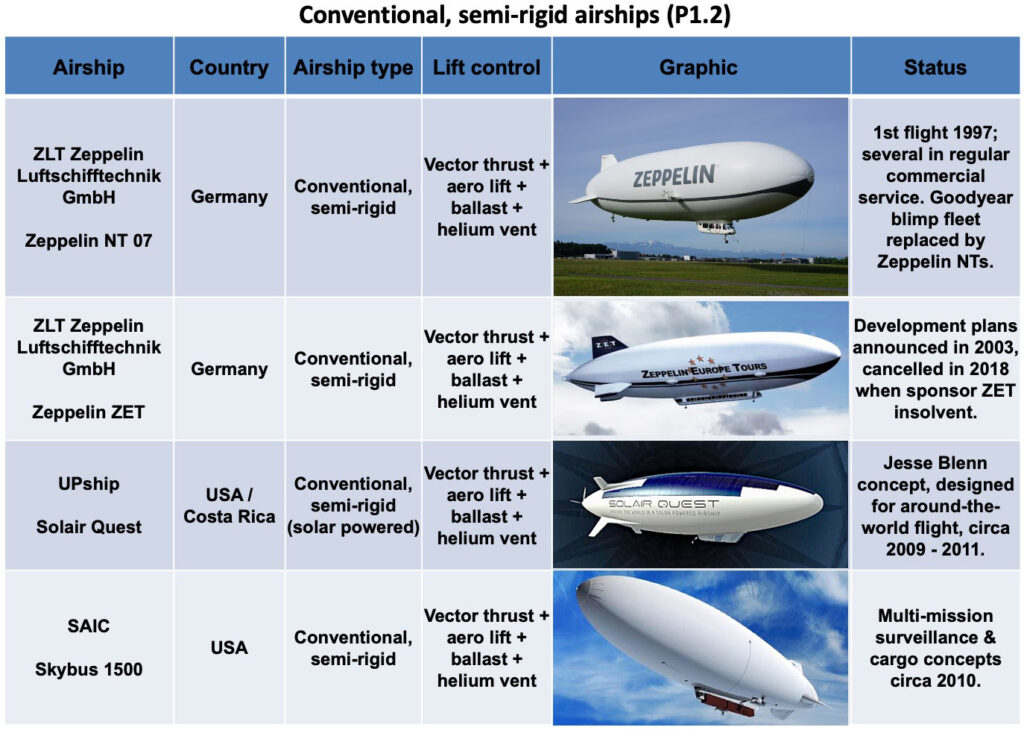

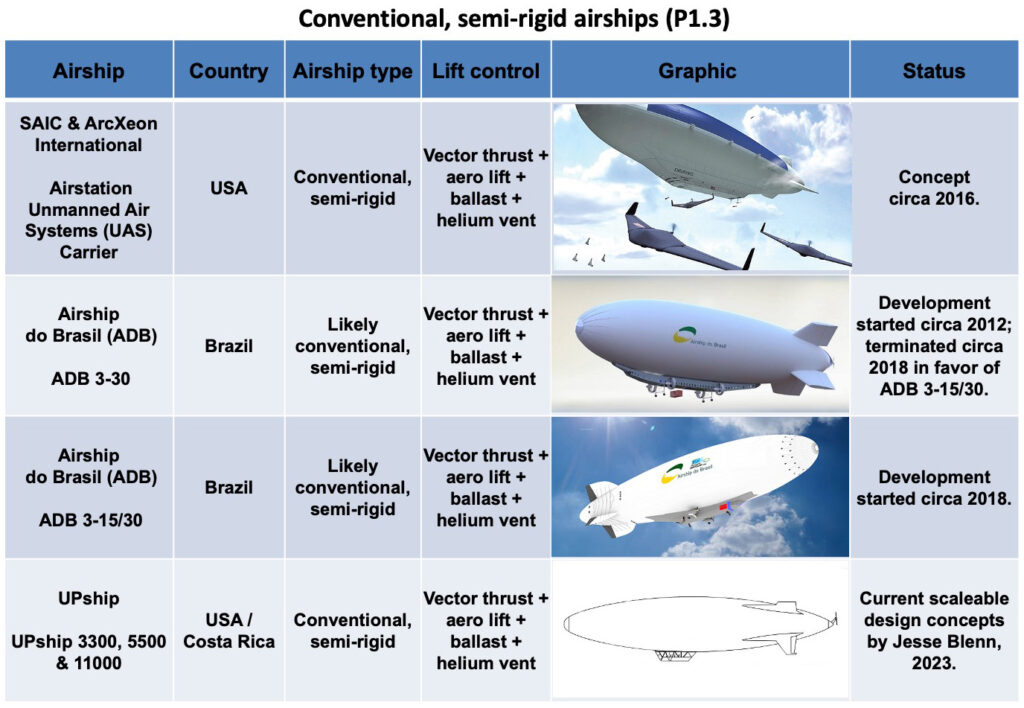

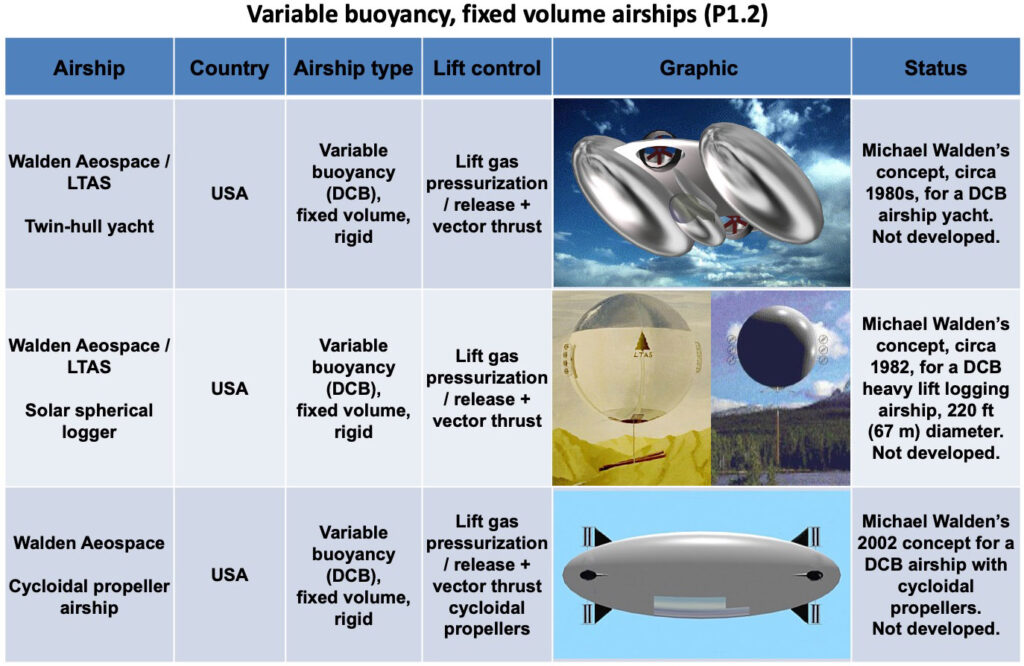

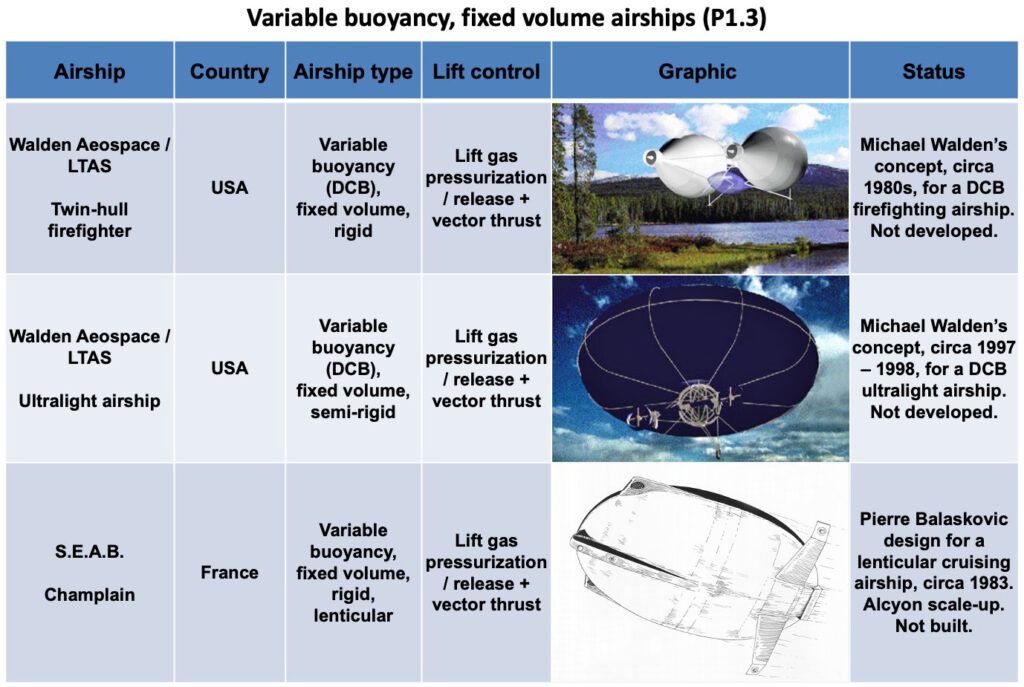

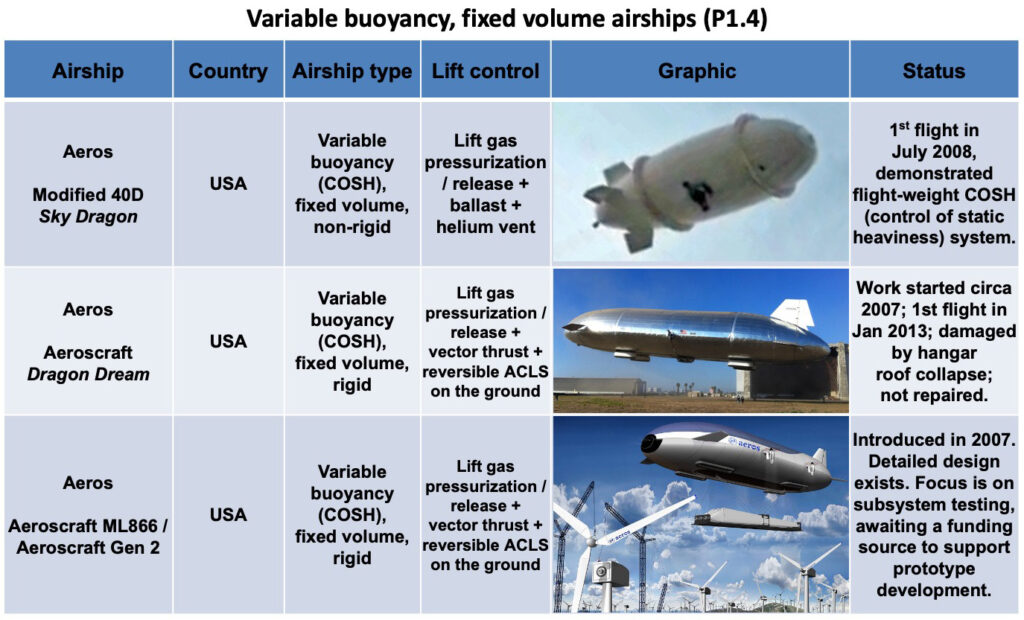

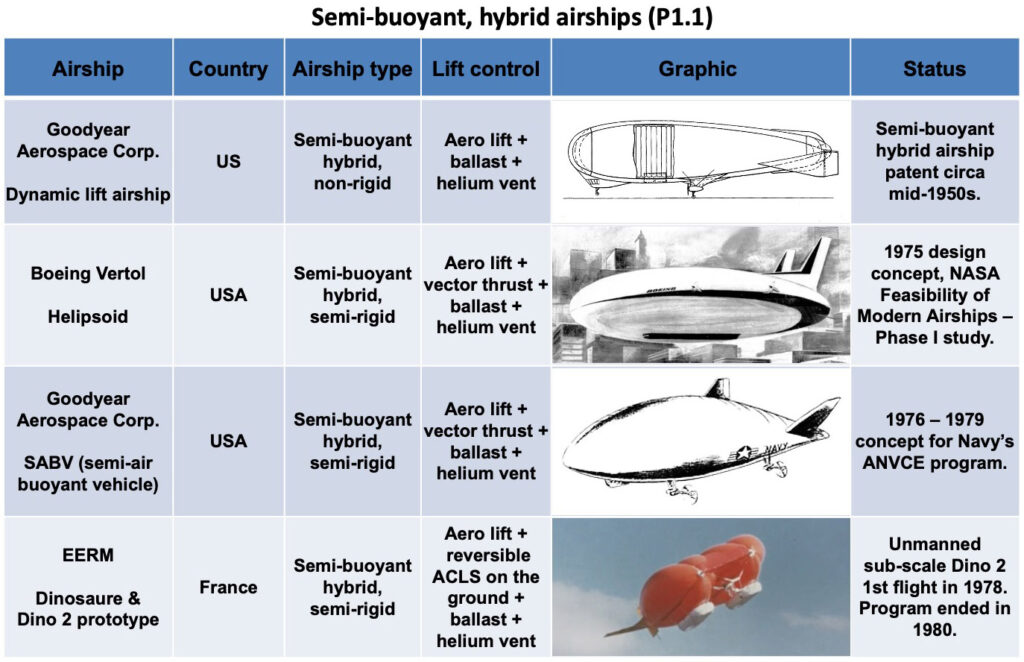

The airships and aerostats reviewed in Modern Airships – Part 1 are summarized in the following set of graphic tables that are organized into the airship type categories listed below:

- Conventional airships

- Rigid airships

- Semi-rigid airships

- Non-rigid airships (blimps)

- Variable buoyancy airships

- Variable buoyancy, fixed volume airships

- Semi-buoyant hybrid air vehicles

- Semi-buoyant, hybrid airships

- Semi-buoyant, airplane / airship hybrids (Dynairship, Dynalifter, Megalifter)

- Semi-buoyant, helicopter / airship hybrids (helistats, Dynastats, rotostats)

- Stratospheric airships / High-Altitude Platform Stations (HAPS)

- Personal gas airships

- Hybrid rocket / balloon (Rockoon) airships

- LTA drones

- Unpowered aerostats

- Tethered aerostats (kite balloons)

- Tethered manned aerostats

- Tethered heavy lift balloons

- Free-flying high-altitude balloons

- Free-flying manned high-altitude balloons

Within each category, each page of the table is titled with the name of the airship type category and is numbered (P1.x), where P1 = Modern Airships – Part 1 and x = the sequential number of the page in that category. For example, “Conventional, rigid airships (P1.2)” is the page title for the second page in the “Conventional, rigid airships” category in Part 1. There also are conventional, rigid airships addressed in Modern Airships – Part 2. Within a category, the airships are listed in the graphic tables in approximate chronological order.

Links to the individual Part 1 articles on these airships are provided in Section 10. Some individual articles cover more than one particular airship. Have fun exploring!

9. Assessment of near-term LTA market prospects

Among the new airships described in Part 1, the following advanced airship seems to be the best candidate for achieving type certification in the next five years:

- LTA Research and Exploration (USA): Pathfinder 1 rigid airship, which is expected to make its first flight in 2024. The program appears to be well funded.

The following airship manufacturers in Part 1 have advanced designs and they seem to be ready to manufacture a first commercial prototype if they can arrange adequate funding:

- AT2 Aerospace (USA): Their Z1 hybrid airship formerly was known as the Lockheed Martin LMH-1. In May 2023, Lockheed Martin exited the hybrid airship business without completing type certification and transitioned that business, including intellectual property and related assets, to the newly formed, commercial company AT2 Aerospace. In June, Straightline Aviation (a former LMH-1 customer) signed a Letter of Intent with AT2 Aerospace, signaling commercial support for the Z1 hybrid airship.

- Aeros (USA): It seems that Aeros has been ready for more than a decade to begin type certification and manufacture a prototype of their Aeroscraft ML866 / Aeroscraft Gen 2 variable buoyancy / fixed volume airship. The firm has reported successful subsystem tests.

Recent changes in European aviation regulations reduce some of the regulatory uncertainty for advanced airship type certification in the EU. The US FAA has not yet published comparable guidance for advanced airships, resulting in continuing regulatory uncertainty in the USA.

The promising airships in Part 1, as listed above, will be competing in the worldwide airship market with candidates identified in Modern Airships – Part 2, which potentially could enter the market in the same time frame. Among the airships described in Part 2, the following advanced airship seems to be the best candidate for achieving type certification in the next five years:

- Flying Whales (France): The LCA60T rigid cargo airship was significantly redesigned in 2021, which resulted in a considerable schedule delay. In March 2023, Flying Whales reported that they expected to complete construction and flight testing of the first production prototype in the 2024 – 2025 timeframe, followed by EASA certification and start of industrial production in 2026. The project appears to be well funded from diverse international sources in France, Canada, China and Morocco. Full-scale production facilities are planned in France, China and Canada and commercial airship operating infrastructure is being planned.

- Hybrid Air Vehicles (UK): The Airlander 10 commercial passenger / cargo hybrid airship is being developed by HAV based on their experience with the Airlander 10 prototype, which flew from 2016 to 2017. In 2022, Valencia, Spain-based Air Nostrum, which operates regional flights, ordered 10 Airlander 10 aircraft, with delivery scheduled for 2026. Also in 2022, Highlands and Islands Airport (HIAL) sponsored a study for introducing the Airlander 10 in Scotland. In April 2023, the regional UK government of South Yorkshire concluded a financial agreement that is expected to lead to the Airlander 10 being manufactured in Doncaster, in the north of England. Things are moving in the right direction. However, FutureFlight reported that “the plan cannot proceed unless HAV secures a strategic investor. It needs at least £100 million to begin construction.”

The following airship manufacturers in Part 2 have advanced designs and they seem to be ready to manufacture a first prototype if they can arrange funding:

- Aerovehicles (USA / Argentina): They claim their AV-10 non-rigid, multi-mission blimp can carry a 10 metric ton payload and be type certified within existing regulations for blimps. This should provide a lower-risk route to market for an airship with an operational capability that does not exist today.

- Atlas LTA Advanced Technology (Israel): After acquiring the Russian firm Augur RosAeroSystems in 2018, Atlas is continuing to develop the ATLANT variable buoyancy, fixed volume heavy lift airship. They also are developing a new family of non-rigid Atlas-6 and -11 blimps and unmanned variants. However, the development plans and schedules have not yet been made public.

- BASI (Canada): The firm has a well-developed design in the MB-30T and a fixed-base operating infrastructure design that seems to be well suited for their primary market in the Arctic.

- Euro Airship (France): The firm reports having production-ready plans for their rigid airship designs. In June 2023, Euro Airship announced plans to build and fly a large rigid airship known as Solar Airship One around the world in 2026.

- Millennium Airship (USA & Canada): The firm has well developed designs for their SF20T and SF50T SkyFreighters, has identified its industrial team for manufacturing, and has a business arrangement with SkyFreighter Canada, Ltd., which would become a future operator of SkyFreighter airships in Canada. In addition, their development plan defines the work needed to build and certify a prototype and a larger production airship.

The 2020s will be an exciting time for the airship industry. We’ll finally get to see if the availability of several different heavy-lift airships with commercial type certificates will be enough to open a new era in airship transportation. Aviation regulatory agencies need to help reduce investment risk by reducing regulatory uncertainty and putting in place an adequate regulatory framework for the wide variety of advanced airships being developed. Customers with business cases for airship applications need to step up, place firm orders, and then begin the pioneering task of employing their airships and building a worldwide airship transportation network with associated ground infrastructure. This will require consistent investment over the next decade or more before a basic worldwide airship transportation network is in place to support the significant use of commercial airships in cargo and passenger transportation and other applications. Perhaps then we’ll start seeing the benefits of airships as a lower environmental impact mode of transportation and a realistic alternative to fixed-wing aircraft, seaborne cargo vessels and heavy, long-haul trucks.

10. Links to the individual articles

The following links will take you to the individual Modern Airships – Part 1 articles. The organization of the following list matches the graphic table.

Note that several of these articles address more than one airship design from the same manufacturer / designer and they may be in different categories (i.e., Airship Industries, Ohio Airships, Walden Aerospace). These designs are listed separately in the above graphic tables and in the following index. The links listed below will take you to the correct article.

CONVENTIONAL AIRSHIPS

Conventional, rigid:

- Airfloat Transport Ltd.: http://lynceans.org/wp-content/uploads/2020/12/Airfloat-HL-converted.pdf

- Airship Advertising / Laws Corp. – rigid airship: https://lynceans.org/wp-content/uploads/2021/08/Airship-Advertising-Laws-Corp_rigid-airship-converted.pdf

- Airship Industries – R40/R130 & R150: https://lynceans.org/wp-content/uploads/2021/08/Airship-Industries-converted-compressed.pdf

- Airships International – Metal clad rigid airships: https://lynceans.org/wp-content/uploads/2023/11/Airships-International.pdf

- Cargo Airship Ltd.: http://lynceans.org/wp-content/uploads/2022/02/Cargo-Airship-Ltd-converted.pdf

- CL CargoLifter GmbH & Co. KGaA – rigid heavy-lift airships: https://lynceans.org/wp-content/uploads/2023/10/CargoLifter-GmbH.pdf

- C.N.R.S. – Titan: https://lynceans.org/wp-content/uploads/2021/08/CNRS_Titan-converted.pdf

- Conrad Airship Company – CA220 & CA80: https://lynceans.org/wp-content/uploads/2021/09/Conrad-Airship-Company_R1-converted-compressed.pdf

- Detroit Aircraft Corporation – ZMC-2 metal-clad airship: https://lynceans.org/wp-content/uploads/2022/09/ZMC2-metalclad-airship-compressed.pdf

- LTA Research and Exploration – rigid airships: https://lynceans.org/wp-content/uploads/2022/03/LTA-Research-and-Exploration-converted-compressed-1.pdf

- Martin Marietta – Model 836 (Navy ANVCE): https://lynceans.org/wp-content/uploads/2021/08/US-Navy_ANVCE-program-airships_1976-converted.pdf

- Rigid Airship Design (RAD) – RA-180 Holland Navigator: https://lynceans.org/wp-content/uploads/2021/08/RAD_RA-180_Holland-Navigator.pdf

- Shell / Aerospace Developments – methane gas transporter: https://lynceans.org/wp-content/uploads/2020/12/Shell-AD_Methane-gas-carrier.pdf

- SPACIAL SA – XEM-4, MLA-24, -32A & -32B: https://lynceans.org/wp-content/uploads/2021/08/SPACIAL-SA_lenticular-airships-converted-compressed.pdf

- Wendel R. Wendel – STAR*FLITE: http://lynceans.org/wp-content/uploads/2022/03/Wendel-R-Wendel_STARFLITE-airship-converted.pdf

- Wren Skyships Ltd. – R.30 & RS.1: https://lynceans.org/wp-content/uploads/2021/08/Wren-Skyships-AAC-converted-compressed.pdf

Conventional, semi-rigid airships:

- Airship do Brasil (ADB) – ADB 3-30 & 3-15/30: https://lynceans.org/wp-content/uploads/2021/04/Airships-do-Brasil-compressed.pdf

- CargoLifter AG – CL160 & Joey: https://lynceans.org/wp-content/uploads/2020/12/Cargolifter-AG.pdf

- Lockheed Martin – Large conventional semi-rigid airship: https://lynceans.org/wp-content/uploads/2023/10/Lockheed-Martin_Large-conventional-semi-rigid-airship.pdf

- SAIC – Skybus 1500: https://lynceans.org/wp-content/uploads/2021/08/SAIC_Skybus-1500-converted.pdf

- SAIC & ArcXeon International – Airstation UAS Carrier: http://lynceans.org/wp-content/uploads/2021/04/SAIC-ArcXeon_UAS-carrier-airship_R1-converted.pdf

- UpShip: https://lynceans.org/wp-content/uploads/2022/02/UPship.pdf

- ZLT Zeppelin Luftschifftechnik GmbH – Zeppelin NT: http://lynceans.org/wp-content/uploads/2021/08/Zeppelin-NT_R1-converted-compressed-1.pdf

- ZLT Zeppelin Luftschifftechnik GmbH – Zeppelin ZET: https://lynceans.org/wp-content/uploads/2020/12/Zeppelin-ZET.pdf

Conventional, non-rigid airships (blimps):

- Advanced Airship Corp. (AAC) – ANR-1: https://lynceans.org/wp-content/uploads/2021/08/Wren-Skyships-AAC-converted-compressed.pdf

- Aeros (Worldwide Aeros Corp.) – Aeros 40 Sky Dragon: https://lynceans.org/wp-content/uploads/2021/09/Aeros-40-Sky-Dragon-blimp_R1-converted.pdf

- Aerospace Development – AD-500: https://lynceans.org/wp-content/uploads/2021/08/Airship-Industries-converted-compressed.pdf

- Airship do Brasil (ADB) ADB 3-X01 & 3-3: https://lynceans.org/wp-content/uploads/2021/04/Airships-do-Brasil_R1-converted.pdf

- Airship Industries – Skyship 500, 500HL & 600: https://lynceans.org/wp-content/uploads/2021/08/Airship-Industries-converted-compressed.pdf

- American Blimp Corp – A-60+, A-150 & A-170 Lightships & Navy MZ-3A (A-170G): http://lynceans.org/wp-content/uploads/2021/08/American-Blimp-Corp-converted-compressed-1.pdf

- ATG / HAV – AT-04 & AT-10: https://lynceans.org/wp-content/uploads/2021/08/ATG_blimps.pdf

- Bell Aerospace Textron – MPA (Navy MPA): https://lynceans.org/wp-content/uploads/2021/08/US-Navy_Maritime-Patrol-Airship-Study_1980-converted.pdf

- Blackwater Airships / Guardian Flight Systems – Polar 400 / 450, Polar 600 & Polar 3000: https://lynceans.org/wp-content/uploads/2021/04/Blackwater_Guardian-Flight-Sys_Polar-airships.pdf

- Goodyear Aerospace – N-Class blimps ZPG-1, -2, -2W & -3W: https://lynceans.org/wp-content/uploads/2021/08/Goodyear_N-class-blimps-converted-compressed.pdf

- Goodyear Aerospace – Civilian blimps GZ-19, -19A, -20, -20A & GZ-22: https://lynceans.org/wp-content/uploads/2021/08/Goodyear_civilian-blimps-converted-compressed.pdf

- Goodyear Aerospace – ZPG-X (Navy ANVCE): https://lynceans.org/wp-content/uploads/2021/08/US-Navy_ANVCE-program-airships_1976-converted.pdf

- Goodyear Aerospace – ZP3G (Navy MPA): https://lynceans.org/wp-content/uploads/2021/08/US-Navy_Maritime-Patrol-Airship-Study_1980-converted.pdf

- Goodyear Aerospace – YEZ-2A (Navy Sentinel 5000 proposal): https://lynceans.org/wp-content/uploads/2021/08/US-Navy_YEZ-2A_Sentinel-1000-5000-converted-compressed.pdf

- Lindstrand Technologies – GA-42: http://lynceans.org/wp-content/uploads/2022/02/Lindstrand-GA-42-GA-22-converted.pdf

- Mav6 LLC – Blue Devil Bock 2 – M1400: https://lynceans.org/wp-content/uploads/2020/12/Mav6_Blue-Devil-Block-2_M1400.pdf

- Solar Airship Ltd. – subscale prototype & Sunship: http://lynceans.org/wp-content/uploads/2022/02/Solar-Airship-Ltd_Sunship-converted-compressed.pdf

- Thunder & Colt – GA-42: http://lynceans.org/wp-content/uploads/2022/02/Thunder-Colt_GA42-blimp-converted.pdf

- US-LTA – Model 138S: https://lynceans.org/wp-content/uploads/2021/08/US-LTA-Corp_Model-138S-blimp.pdf

- Westinghouse Airships Inc. (WAI) – Sentinel 1000 & 5000 (Navy YEZ-2A): https://lynceans.org/wp-content/uploads/2021/08/US-Navy_YEZ-2A_Sentinel-1000-5000-converted-compressed.pdf

- West Deutsche Lufterwerbung GmbH (WDL) – WDL-1 & -1B: https://lynceans.org/wp-content/uploads/2021/08/WDL-converted-compressed.pdf

VARIABLE BUOYANCY AIRSHIPS

Variable buoyancy, fixed volume airships:

- Aeros – Dragon Dream & modified 40D Sky Dragon: https://lynceans.org/wp-content/uploads/2021/04/Aeros_Dragon-Dream.pdf

- Aeros – Aeroscraft ML866 / Aeroscraft Generation 2: https://lynceans.org/wp-content/uploads/2021/08/Aeros_Aeroscraft.pdf

- S.E.A.B. – Champlain: http://lynceans.org/wp-content/uploads/2021/08/SEAB_Alcyon-Champlain_lenticular-airships-converted.pdf

- Vaeth & Stehling – Helium Horses: http://lynceans.org/wp-content/uploads/2022/03/Vaeth-Stehling_Helium-Horses-converted-compressed.pdf

- Walden Aerospace / LTAS – lenticular, toroidal, variable buoyancy airships:https://lynceans.org/wp-content/uploads/2021/08/Walden-LTAS_Lenticular-toroidal-DCB-airships_R1.pdf

SEMI-BUOYANT AIR VEHICLES

Semi-buoyant hybrid airships:

- Advanced Technology Group (ATG) – SkyCat & SkyKitten: http://lynceans.org/wp-content/uploads/2021/08/ATG_SkyCat-SkyKitten-converted-compressed-1.pdf

- ATG / Hybrid Air vehicles (HAV) – Condor: http://lynceans.org/wp-content/uploads/2021/08/ATG_HAV_Condor_R1-converted.pdf

- AT2 Aerospace – Z1: https://lynceans.org/wp-content/uploads/2023/06/AT2-Aerospace.pdf

- Boeing Vertol – Helipsoid: https://lynceans.org/wp-content/uploads/2021/08/Boeing-Vertol_Helipsoid-converted.pdf